Crop trace element organic complex fertilizer and preparation method thereof

A technology of trace elements and organic complexation, applied in fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of large loss of raw materials, large residues, poor absorption of crops, etc., to improve disease resistance, improve growth quality, The effect of shortening the crop growth cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

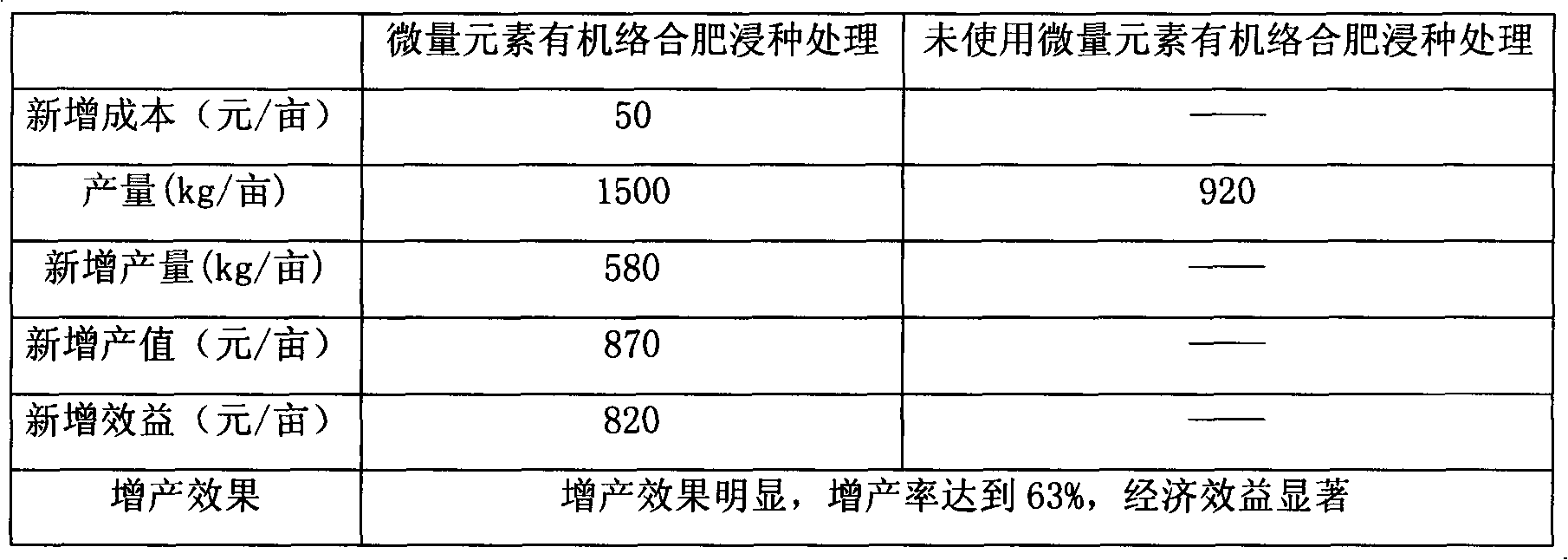

Image

Examples

Embodiment 1

[0030] Based on the preparation of 100kg crop trace element organic complex fertilizer:

[0031] 1. Add 20kg of water to the reaction kettle, start stirring, weigh 6kg of urea into the kettle and dissolve it completely;

[0032] 2. Mix 0.2kg citric acid, 3kg ZnSO 4 , 2kg borax and 2kg ammonium molybdate are respectively added in the kettle according to the amount and then stirred, dissolved and mixed;

[0033] 3. Put 0.8kg CuSO 4 、3kg FeSO 4 and 0.3kg MnSO 4 After weighing, add to the kettle and stir to dissolve and mix;

[0034] 4. Under the condition of stirring, add 8kg vitamin B3 into the reaction kettle to dissolve. At this time, vitamins, urea, citric acid and CuSO 4 , FeSO 4 , ZnSO 4 , MnSO 4 , borax, and ammonium molybdate complexation reaction;

[0035] 5. Under stirring conditions, add 1 kg of titanium trichloride after weighing, at this moment, titanium trichloride and vitamin B3, urea, and citric acid that did not participate in the reaction in 4 undergo a...

Embodiment 2

[0041] Based on the preparation of 100kg crop trace element organic complex fertilizer:

[0042] 1. Add 20.5kg of water to the reaction kettle, start stirring, weigh 15kg of urea into the kettle and dissolve it completely;

[0043] 2. Mix 2kg citric acid, 0.5kg ZnSO 4 , 3kg borax and 0.3kg ammonium molybdate were added to the kettle and stirred, dissolved and mixed successively according to the amount;

[0044] 3. Put 4kg CuSO 4 , 0.5kg FeSO 4 and 5kg MnSO 4 After weighing, add to the kettle and stir to dissolve and mix;

[0045] 4. Under stirring conditions, add 3kg vitamin B9 and 1kg vitamin C into the reaction kettle to dissolve. At this time, vitamins, urea, citric acid and CuSO 4 , FeSO 4 , ZnSO 4 , MnSO 4 , borax, and ammonium molybdate complexation reaction;

[0046] 5. Under stirring conditions, add 4kg of titanium tetrachloride after weighing, at this moment, titanium tetrachloride and vitamin C, vitamin B9, urea, and citric acid that do not participate in th...

Embodiment 3

[0052] Based on the preparation of 100kg crop trace element organic complex fertilizer:

[0053] 1. Add 50kg of water to the reaction kettle, start stirring, weigh 11kg of urea into the kettle and dissolve it completely;

[0054] 2. Mix 0.5kg citric acid, 1kg ZnSO 4 , 3.5kg borax and 1.5kg ammonium molybdate were added to the kettle and stirred, dissolved and mixed successively according to the amount;

[0055] 3. Put 2.5kg CuSO 4 、3kg FeSO 4 and 2.6kg MnSO 4 After weighing, add to the kettle and stir to dissolve and mix;

[0056] 4. Under stirring conditions, add 1.4kg vitamin B1 and 2kg vitamin E into the reaction kettle to dissolve. At this time, vitamins, urea, citric acid and CuSO 4 , FeSO 4 , ZnSO 4 , MnSO 4 , borax, and ammonium molybdate complexation reaction;

[0057] 5. Under stirring conditions, add 0.8kg of titanium sulfate after weighing, at this time, titanium sulfate and vitamin B1, vitamin E, urea and citric acid that do not participate in the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com