Basalt fiber polypropylene composite material enhanced by expansion flame retardants and method for preparing same

A basalt fiber, intumescent flame retardant technology, which is applied in the field of basalt fiber reinforced intumescent flame retardant polypropylene composite material and its preparation field, can solve problems such as toxic gas smoke, metal mold corrosion, environmental pollution, etc., and achieves improved mechanical properties and flame retardancy. Good effect, enhanced tensile strength and tensile modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

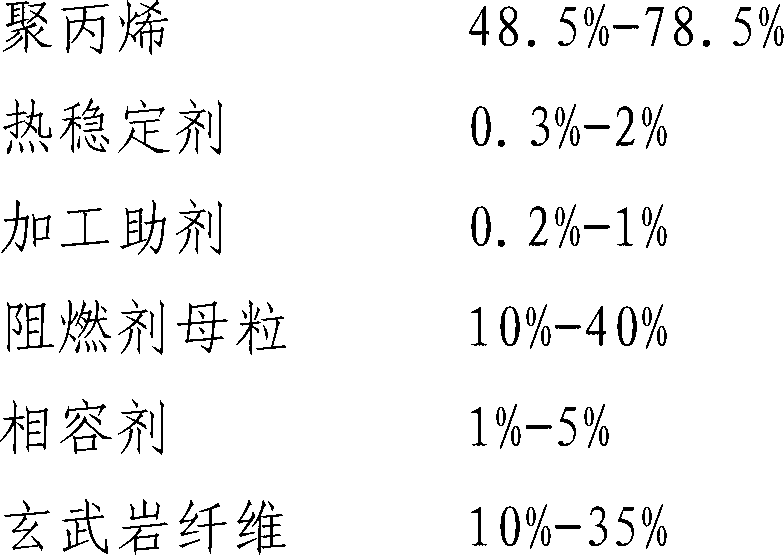

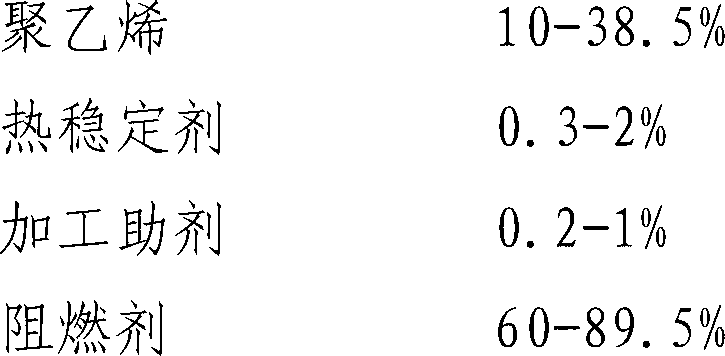

[0027] Preparation of flame retardant masterbatch: 12 kg of bimodal polyethylene PE FB2230 (Borealis), 0.5 kg of dilauryl thiodipropionate, 0.5 kg of erucamide, 1 kg of calcium stearate, 85.5 kg of melamine polyphosphate Salt and pentaerythritol compound flame retardant ANTI-610 (Shanghai Petrochemical Research Institute) is melted, mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1, extruded and granulated, and the extrusion temperature is 180 ° C ~ 230 ° C , and finally made a flame retardant masterbatch.

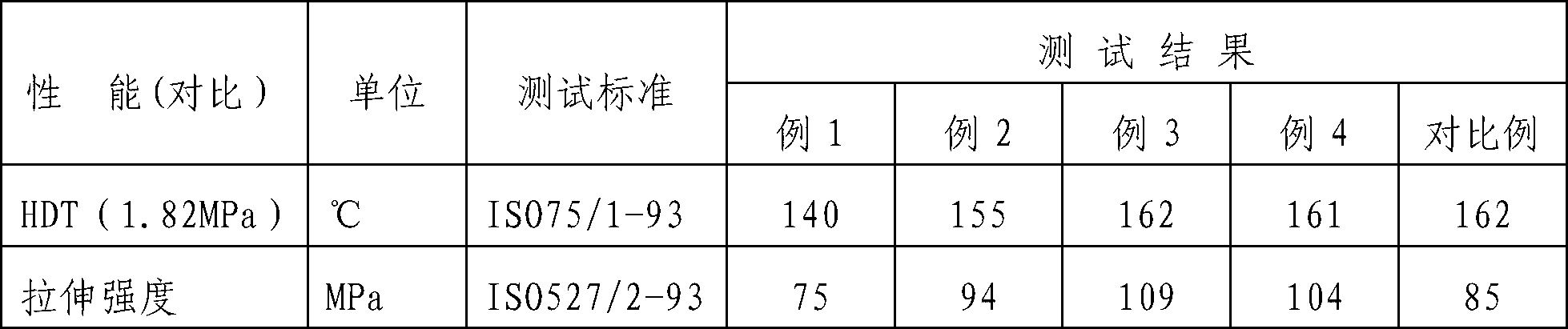

[0028] 58 kg of polypropylene PP M2600R (Shanghai Petrochemical), 0.8 kg of heat stabilizer p-phenylenediamine, 0.5 kg of heat stabilizer dilauryl thiodipropionate, 0.3 kg of processing aid erucamide, 5 kg of maleic anhydride The grafted polyethylene was melted, mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1. 12 kg of basalt chopped fiber CBF15-12 (Shanxi Baseout Technology), and 23.4 kg of flame reta...

Embodiment 2

[0029] Preparation of flame retardant masterbatch: 36 kg of bimodal polyethylene PE FB2230 (Borealis), 0.5 kg of stabilizer diphenylamine, 0.5 kg of stabilizer dihydroquinoline, 0.5 kg of erucamide, 1 kg of calcium stearate, 60 kilograms of melamine polyphosphate and pentaerythritol compound flame retardant 50A-2 (Shandong Murray) were melted, mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1, extruded and granulated, and the extrusion temperature was 180 ℃ ~ 230 ℃, finally made the flame retardant masterbatch.

[0030] 32 kg of polypropylene PP M2600R (Shanghai Petrochemical), 1.5 kg of heat stabilizer diphenylamine, 1 kg of processing aid calcium stearate, 2.5 kg of maleic anhydride grafted polypropylene and ethylene-α-ethylene-octene copolymer PC-8C (Guangdong Bochen) is melted, mixed and dispersed in a twin-screw extruder with a length-to-diameter ratio of 40:1, 25 kg of basalt chopped fiber CBF15-12 (Shanxi Bassett Technology), 38 kg of ...

Embodiment 3

[0032] Preparation of flame retardant masterbatch: 22 kg of bimodal polyethylene PE FB2310 (Borealis), 0.5 kg of stabilizer dilauryl thiodipropionate, 0.5 kg of stabilizer dihydroquinoline, 1 kg of processing aid stearin Zinc acid, 1 kg of processing aid erucamide, 75 kg of amine polyphosphate and pentaerythritol compound flame retardant FP-2200 (ADK) were melt mixed and dispersed in a single-screw extruder with a length-to-diameter ratio of 35:1. granulation, the extrusion temperature is 180°C to 230°C, and finally the flame retardant masterbatch is obtained.

[0033] 30 kg of polypropylene PP S900 (Lanzhou Petrochemical), 0.2 kg of heat stabilizer dilauryl thiodipropionate, 0.3 kg of heat stabilizer dihydroquinoline, 0.5 kg of processing aid erucamide, 2 kg of maleic anhydride Branched polypropylene is melted, mixed and dispersed in a twin-screw extruder with an aspect ratio of 40:1, 35 kg of basalt chopped fiber CBF15-12 (Shanxi Bassett Technology), and 32 kg of flame retar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com