High-protein microbiological feed and preparation method thereof

A microbial feed and high-protein technology, applied in the field of resource environment and biological feed, can solve the problems of scum influence and difficult resource utilization of scum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] 1. Preparation of expanded culture medium

[0068] Expanded culture solution formula 1: Weigh the materials according to the following weights: molasses 2Kg, water 8.5Kg, urea 0.08Kg, potassium dihydrogen phosphate 0.03Kg, adjust the pH to 5.0, and steam sterilize at 115°C for 20 minutes.

[0069] Expanded culture solution formula 2: Weigh the materials according to the following weights: molasses 1.6Kg, water 7.5Kg, urea 0.01Kg, potassium dihydrogen phosphate 0.01Kg, adjust the pH to 6.0, and steam sterilize at 115°C for 20 minutes.

[0070] Expanded culture medium formula 3: Weigh the following materials: molasses 1.83Kg, water 8.1Kg, urea 0.05Kg, potassium dihydrogen phosphate 0.02Kg, adjust the pH to 5.5, and steam sterilize at 115°C for 20 minutes.

[0071] 2. Preparation of expansion medium

[0072] Expanded medium formula 1: Weigh the materials according to the following weight: 4.5Kg of bran, 0.1Kg of sucrose, 4.5Kg of water, 0.01Kg of diammonium hydrogen phosp...

Embodiment 1

[0077] 1. Preparation of beneficial fermentation agent: inoculate Trichoderma longhandii and Candida utilis into the expansion medium formula 1 respectively, and cultivate Trichoderma longhandi for 5 days under aerobic conditions at 25~30° C. to produce Candida prion was cultured for 1 day, and the culture was dried at 40°C under normal pressure and then crushed evenly. The effective number of viable bacteria in the obtained bacterial preparation was more than 200 million / g, and the rate of miscellaneous bacteria was lower than 30%.

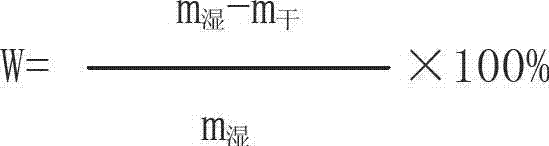

[0078] 2. Sugar cane sugar factory scum pretreatment: the sugar cane sugar factory mixed juice scum is dehydrated through plate and frame pressure filtration to obtain wet scum with a water content of 50%, which is crushed for later use.

[0079] 3. Ingredients: Weigh mixed raw materials according to the following weight: wet scum 96.8kg (including absolute dry material 48.4kg), ammonium chloride 0.5kg, dipotassium hydrogen phosphate 0.2kg, magnes...

Embodiment 2

[0084] 1. Preparation of beneficial fermentation agent: plant Aspergillus niger into the expansion medium formula 2, cultivate it under aerobic conditions at 25-30°C for 4 days, and grind the culture evenly after air-drying under normal pressure at 38°C. The effective number of viable bacteria of the obtained bacterial agent is greater than 200 million / g, and the rate of miscellaneous bacteria is lower than 30%; the beer yeast is inoculated into the expanded culture solution 1, and cultivated for 2 days at 25-30°C under aerobic conditions, and the obtained bacteria The effective number of viable bacteria of the agent is more than 100 million / g, and the miscellaneous bacteria rate is lower than 20%.

[0085] 2. Sugarcane sugar factory scum pretreatment: the sugarcane sugar factory mixed juice scum is dehydrated through plate and frame pressure filtration to obtain wet scum with a water content of 40%, which is crushed for later use.

[0086] 3. Ingredients: Weigh the mixed ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com