Preparation method and application of microwave-assisted synthesized chlorine-element-doped surface molecular imprinting photocatalyst

A surface molecular imprinting and photocatalyst technology, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Slow rate and other issues, to achieve the effect of improving photocatalytic activity, improving photodegradation activity, and reducing the bandgap width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

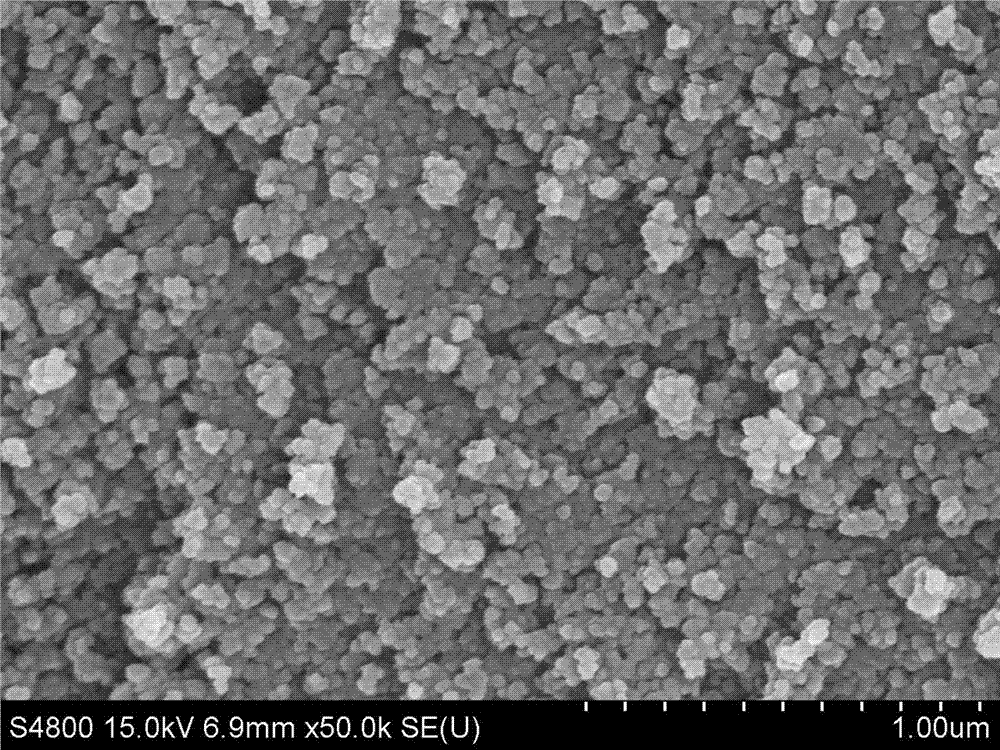

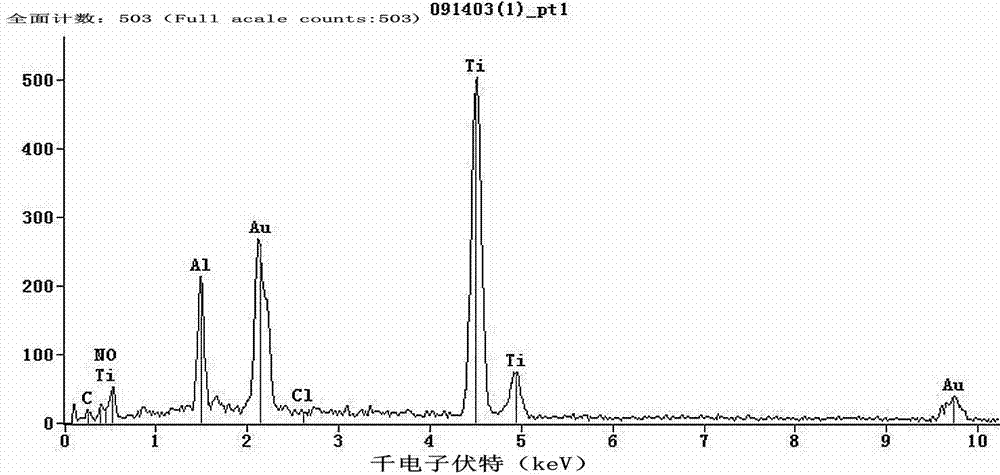

[0031] (1) Add 10mL tetrabutyl titanate slowly and dropwise to 100mL absolute ethanol solution, stir at room temperature for 30min; add 100mL 1mol / L dilute hydrochloric acid dropwise to the above solution and stir for 6h, aging for 2h until To form a gel; dry the resulting gel in a vacuum drying oven at 70°C for 10 hours, take it out and put it in a muffle furnace at 500°C for 4 hours, and cool it naturally to obtain a chlorine-doped titanium dioxide composite photocatalyst;

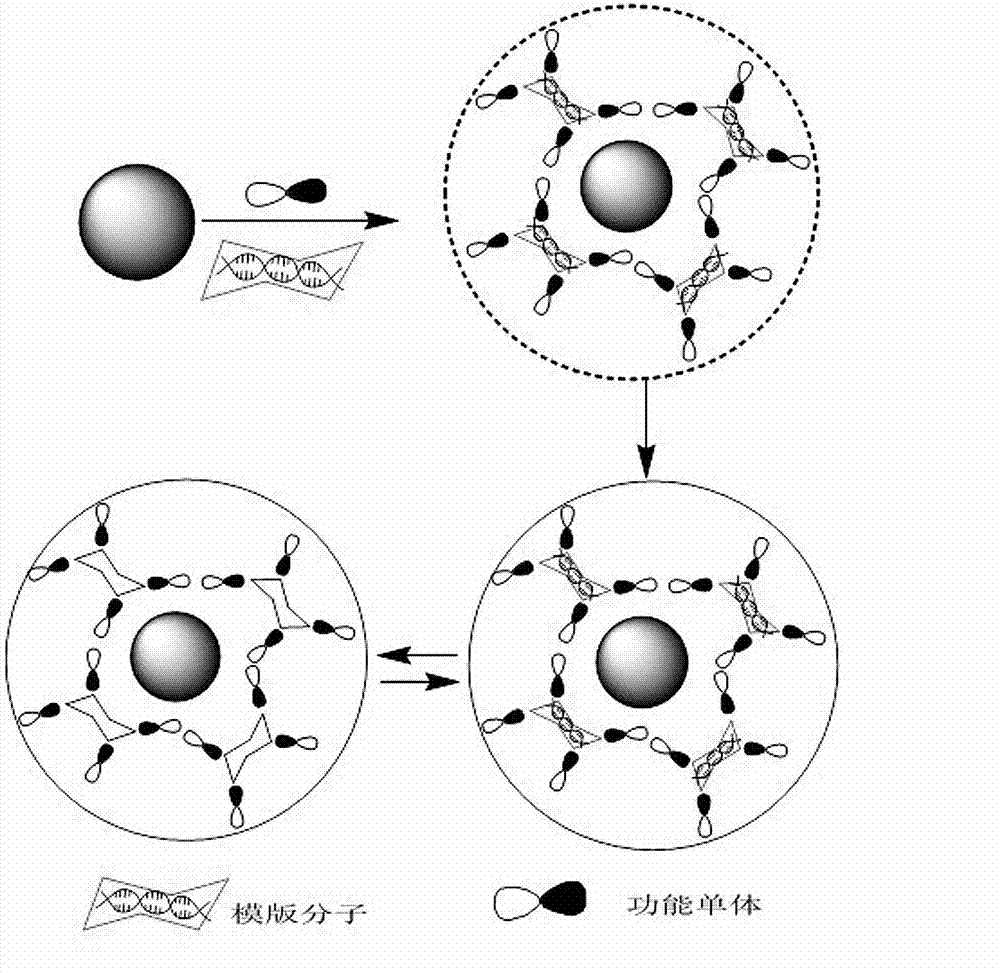

[0032] (2) Completely dissolve 1mmol of tetracycline template molecule in 30mL acetonitrile. After stirring in a water bath at 25°C for 30min, add the functional monomer (4-vinylpyridine) to the above solution and stir for 1h, then add the crosslinking agent (trimethylol Base propane acrylate) and initiator (azobisisobutyl cyanide) are stirred for 30 minutes, where the ratio of the amount of template molecule: functional monomer: crosslinking agent: initiator is 1:2:6:0.3; take 1g (1) Add the photocatalyst ...

Embodiment 2

[0035] According to the steps in Example 1, the difference is that in (2), 1mmol of tetracycline template molecules are completely dissolved in 30mL of toluene, and after stirring in a water bath at 25°C for 30 minutes, the functional monomer (4-vinylpyridine) is added to the above solution Stir for 1h, then add crosslinking agent (trimethylolpropane acrylate) and initiator (azobisisobutyronitrile) and stir for 30min, where template molecule: functional monomer: crosslinking agent: the amount of initiator The ratio is 1:2:6:0.3; take 1g of the photocatalyst synthesized in (1) and add it to the solution and keep stirring for 30min. Then inject the solution into a microwave reaction flask. Microwave 600W, 70℃ for 60min, magnetic force during heating The stirring speed is 2000 rpm, natural cooling, centrifugal separation of the obtained solution to obtain the solid matter, placed in a 60 ℃ vacuum drying oven for 12 hours; the obtained solid powder is Soxhlet extracted and eluted te...

Embodiment 3

[0038] According to the steps in Example 1, the difference is that in (2), 1 mmol of tetracycline template molecules are completely dissolved in 30 mL of methanol, and the functional monomer (4-vinylpyridine) is added to the above solution after stirring in a water bath at 25°C for 30 minutes. Stir for 1h, then add crosslinking agent (trimethylolpropane acrylate) and initiator (azobisisobutyronitrile) and stir for 30min, where template molecule: functional monomer: crosslinking agent: the amount of initiator The ratio is 1:2:6:0.3; take 1g of the photocatalyst synthesized in (1) and add it to the solution and keep stirring for 30min. Then inject the solution into a microwave reaction flask. Microwave 600W, 70℃ for 60min, magnetically stir during heating Rotation speed is 2000rpm, natural cooling, centrifugal separation of the resulting solution to obtain the solid matter, placed in a 60℃ vacuum drying oven for 12h; the obtained solid powder is Soxhlet extracted and eluted templa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com