Method for coating Ti-based denitration catalyst on honeycomb ceramic

The technology of denitration catalyst and honeycomb ceramics is applied in the field of preparation of coated ceramic honeycomb denitration catalyst, which can solve the problems of cumbersome and complicated processes, and achieve the effects of simple process, improved loading rate and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

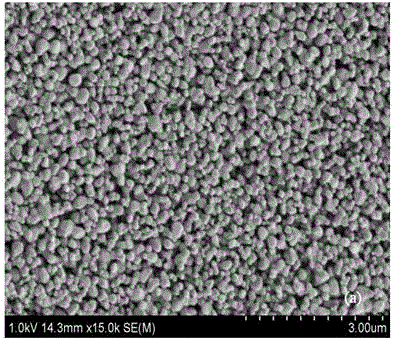

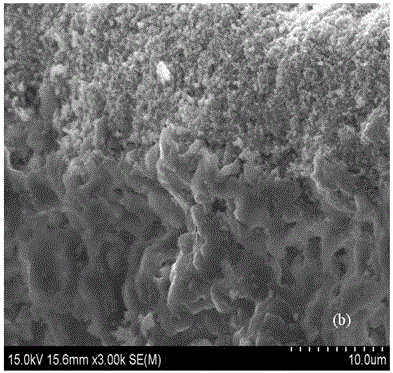

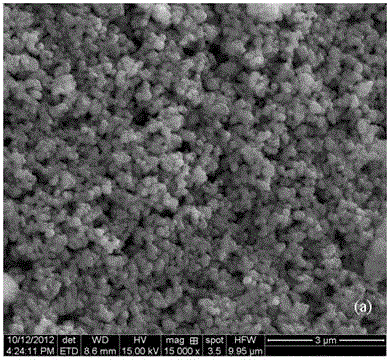

Image

Examples

preparation example Construction

[0029] The preparation of the catalyst is not an innovative point of the present invention. Those skilled in the art can prepare the required Ti-based denitration catalyst according to the method disclosed in the prior art according to the need, or purchase the required Ti-based denitration catalyst on the market. Below only with V 2 o 5 -WO 3 / TiO 2 Catalyst and the amorphous composite oxide denitration catalyst (CeTiO x ) as an example to illustrate the coating method of the present invention.

[0030] In the coating method of the automobile exhaust gas purification catalyst provided by the invention, the coating effect is evaluated by ultrasonic cleaning experiments. The method is to use an analytical balance to weigh the catalyst-coated carrier, immerse it in deionized water and ultrasonically sound for 10 min, take it out, blow off the residual liquid in the hole, dry it at 100 ° C, roast at 500 ° C for 2 h, and then use Analytical balance weighs the weight of the ca...

Embodiment 1

[0032] Weigh 6.08 g oxalic acid, 12.77 g ammonium tungstate (in WO 3 accounted for 10% of the total catalyst content) was dissolved in 150 ml deionized water, and stirred thoroughly to obtain a salt solution. Add 100 g of anatase titanium dioxide to the salt solution, and evaporate to dryness in an oil bath at 75°C. Drying overnight at 100°C and calcination at 500°C for 2 h yielded 10% WO 3 / TiO 2 powder catalyst. Grind and sieve the catalyst into a powder larger than 80 mesh, and weigh it.

[0033] According to the 10% WO obtained above 3 / TiO 2 Powder catalyst, weigh a certain amount of ammonium metavanadate (in V 2 o 5 Accounting for 1% of the total catalyst content) and oxalic acid, dissolved in 150 ml deionized water. After complete dissolution, add the prepared 10% WO 3 / TiO 2 The powder catalyst was evaporated to dryness in an oil bath at 75°C. Dry overnight at 100°C and bake at 500°C for 2 h to obtain 1% V 2 o 5 / 10% WO 3 / TiO 2 catalyst. Grind and siev...

Embodiment 2

[0039] Weigh 3.04 g oxalic acid, 6.39 g ammonium tungstate (in WO 3 Accounting for 5% of the total catalyst content) was dissolved in 150 ml of deionized water and stirred thoroughly to obtain a salt solution. Add 100 g of anatase titanium dioxide to the salt solution, and evaporate to dryness in an oil bath at 75 °C. Drying overnight at 100 °C and calcination at 500 °C for 2 hours yielded 5% WO 3 / TiO 2 powder catalyst. The catalyst is ground and sieved into a powder larger than 80 mesh.

[0040] Based on the 5%WO obtained above 3 / TiO 2 powder catalyst, weigh a certain amount of ammonium metavanadate (in V 2 o 5 Accounting for 1% of the total catalyst content) and oxalic acid, dissolved in 150 ml deionized water. After complete dissolution, add the prepared 5% WO 3 / TiO 2 The powder catalyst was evaporated to dryness in an oil bath at 75 °C. Dry overnight at 100 °C and bake at 500 °C for 2 h to obtain 1% V 2 o 5 / 5%WO 3 / TiO 2 catalyst. Grind and sieve the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com