Fluorine-based surfactant, and coating composition and resist composition each using same

A technique for surfactants and compositions, which is applied in the field of coating compositions and resist compositions using the surfactants, can solve problems such as difficulty in maintaining the performance of surfactants, and achieve excellent leveling and excellent reduction , the effect of high surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

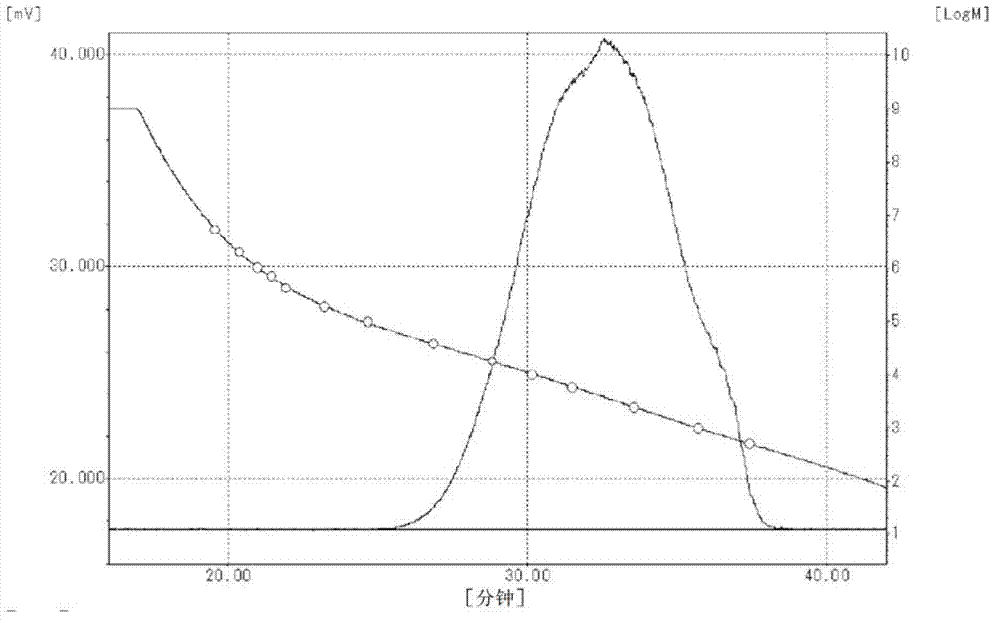

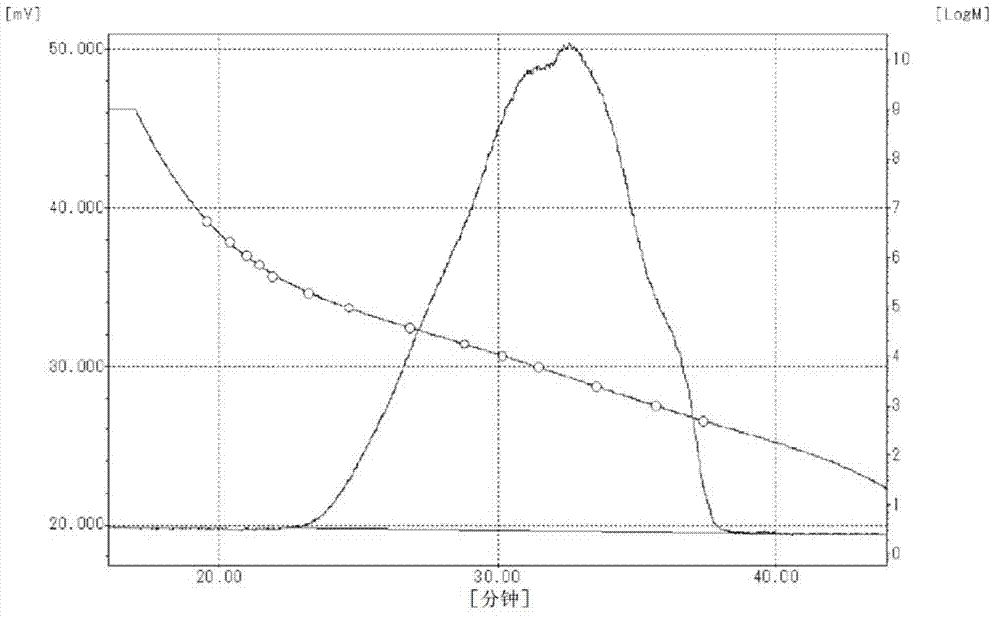

[0132] Examples and comparative examples are given below to describe the present invention in further detail. In addition, in the following examples, the weight average molecular weight (Mw) and the number average molecular weight (Mn) were calculated|required by GPC measurement under the following conditions.

[0133] [GPC measurement conditions]

[0134] Measuring device: "HLC-8220GPC" manufactured by TOSOH Corporation,

[0135] Column: Guard column "HHR-H" manufactured by TOSOH Corporation (6.0mmI.D.×4cm)

[0136] + "TSK-GEL GMHHR-N" manufactured by TOSOH Corporation (7.8mmI.D.×30cm)

[0137] + "TSK-GEL GMHHR-N" manufactured by TOSOH Corporation (7.8mmI.D.×30cm)

[0138] + "TSK-GEL GMHHR-N" manufactured by TOSOH Corporation (7.8mmI.D.×30cm)

[0139] + "TSK-GEL GMHHR-N" manufactured by TOSOH Corporation (7.8mmI.D.×30cm)

[0140] Detector: ELSD ("ELSD2000" manufactured by Ortec Ltd.)

[0141] Data processing: "GPC-8020Model II data analysis version 4.30" manufactured by...

Synthetic example 1)

[0163] Into a glass flask equipped with a stirring device, a thermometer, a condenser, and a dropping device, add 20 parts by mass of a perfluoropolyether compound having hydroxyl groups at both ends represented by the following formula (a2-1-1), and diisocyanate as a solvent. 20 parts by mass of propyl ether, 0.02 parts by mass of p-methoxyphenol as a polymerization inhibitor, and 3.1 parts by mass of triethylamine as a neutralizing agent. Stirring was started under air flow, and the inside of the flask was kept at 10°C. 2.7 parts by mass of acryloyl chloride were added dropwise over 1 hour. After completion of the dropwise addition, the mixture was stirred at 10° C. for 1 hour, heated and stirred at 30° C. for 1 hour, then heated to 50° C. and stirred for 10 hours to perform a reaction, and the disappearance of acryloyl chloride was confirmed by gas chromatography. Next, after adding 40 parts by mass of diisopropyl ether as a solvent, washing by mixing and stirring 80 parts ...

Synthetic example 2)

[0170] Add 30 parts by mass of a block copolymer of ethylene oxide and propylene oxide represented by the following formula (B1'-1) and 2.8 parts by mass of acrylic acid into a glass flask equipped with a stirring device, a thermometer, a condenser tube, and a dropping device parts, 64 parts by mass of toluene as a solvent, 0.03 parts by mass of phenothiazine as a polymerization inhibitor, and 0.6 parts by mass of methanesulfonic acid as a catalyst. Stirring was started under air flow, heated to 120° C., and refluxed for dehydration. After confirming that 0.63 parts by mass of dehydration was present, it was cooled to 65°C and neutralized with triethylamine. After neutralization, the temperature was raised to 85°C, 2.3 parts by mass of ion-exchanged water was added, liquid separation was performed, and the lower layer was separated. The washing operation was repeated until the pH of the lower layer was measured to be 7 or higher. After cooling to 30° C., it was diluted with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com