Preparation method of nano-hydroxyapatite/chitosan

A nano-hydroxyapatite and chitosan technology, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as lack, and achieve the effects of regular morphology, simple preparation process and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

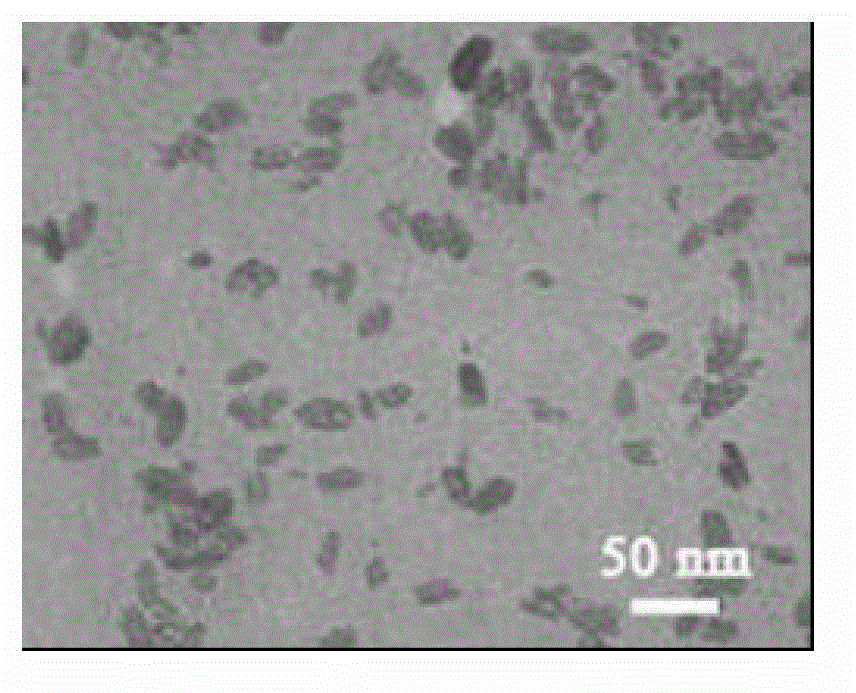

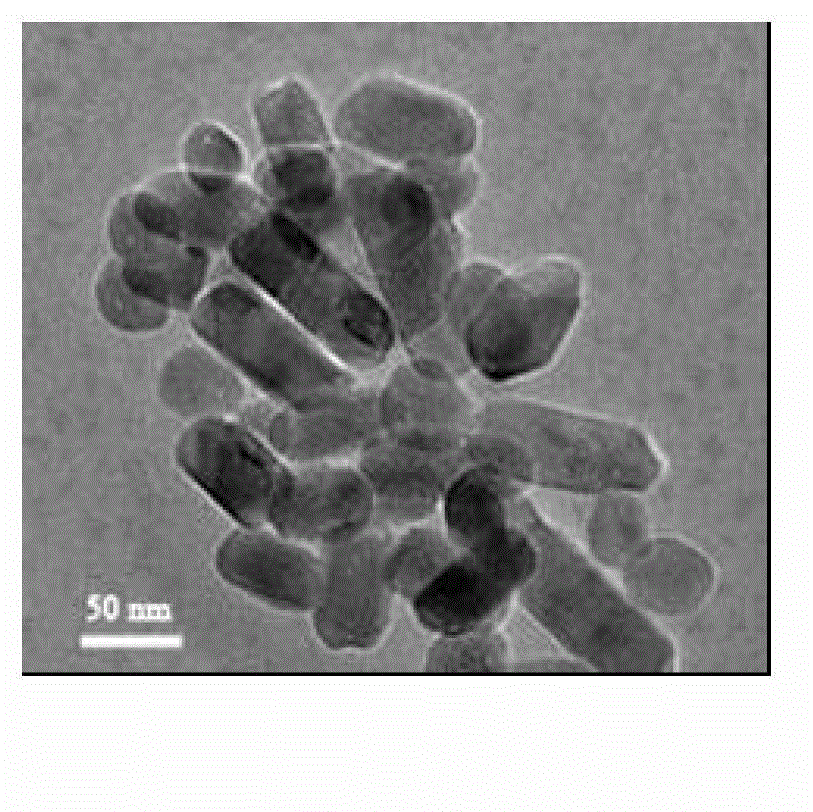

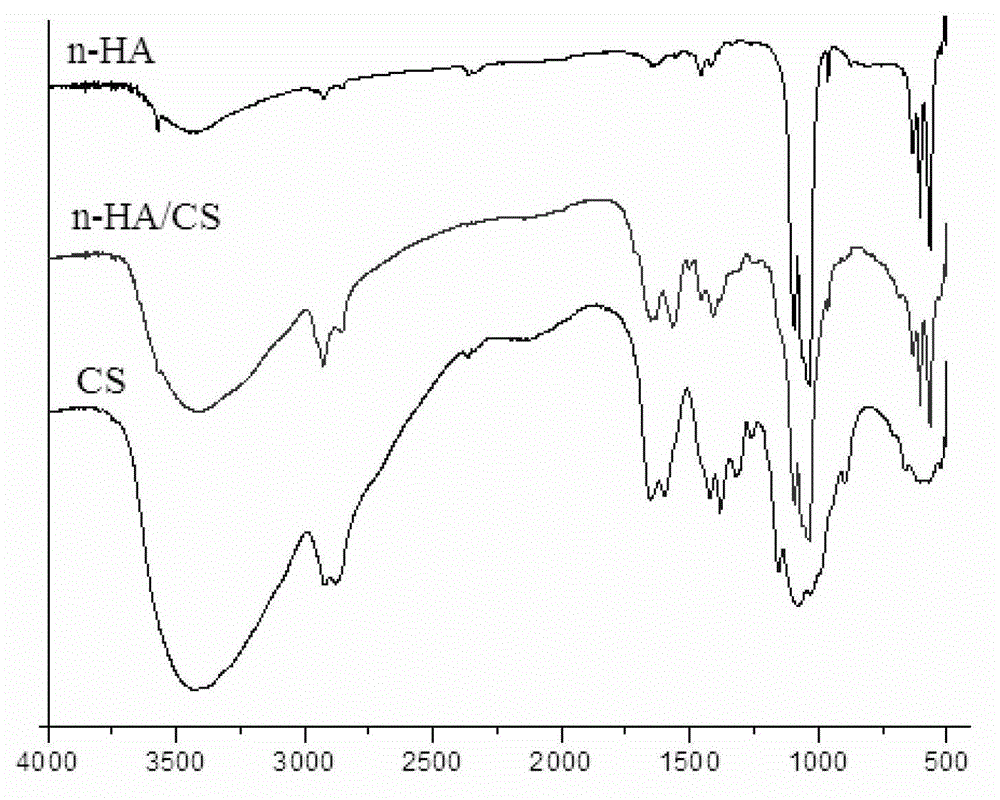

Image

Examples

Embodiment 1

[0022] Embodiment one: a kind of preparation method of nano-hydroxyapatite / chitosan, comprises the following processing steps:

[0023] (1) Synthesis of nano-hydroxyapatite: Mix sodium phosphate solution, calcium chloride solution and cetyltrimethylammonium bromide solution (CTAB) to obtain a reaction system, in which Ca 2+ The ion concentration is 0.08mmol·L -1 , the concentration of phosphate ion is 0.048mmol·L -1 , the concentration of CTAB is 8×10 -4 mol L -1 , and the molar ratio of calcium ions to phosphate ions is 5:3; react for 12 to 96 hours, and adjust the pH value to remain at 8; filter the obtained product through a 0.22 μm microporous membrane after being centrifuged in a centrifuge, and The filtered solid was alternately washed twice with water and absolute ethanol, and then vacuum-dried overnight at 30°C to obtain nano-hydroxyapatite powder;

[0024] (2) Dissolve 0.05g of chitosan powder in 5mL of 1% acetic acid aqueous solution to obtain a chitosan solution...

Embodiment 2

[0029] Embodiment two: a kind of preparation method of nano-hydroxyapatite / chitosan, comprises the following processing steps:

[0030] (1) Synthesis of nano-hydroxyapatite: Mix sodium hydrogen phosphate solution, calcium chloride solution and cetyltrimethylammonium bromide solution (CTAB) to obtain a reaction system, in which Ca 2+ The ion concentration is 500mmol·L -1 , the concentration of phosphate ion is 300mmol·L -1 , the concentration of CTAB is 10.5×10 -4 mol L -1 , and the molar ratio of calcium ions to phosphate ions is 5:3; react for 96 hours, and adjust the pH value to remain at 14; filter the obtained product through a 0.22 μm microporous membrane after centrifugation, and filter to obtain The solid was alternately washed 20 times with water and absolute ethanol, and then dried in vacuum at 80°C overnight to obtain nano-hydroxyapatite powder;

[0031] (2) Dissolve 1.5g of chitosan powder in 500mL of 5% acetic acid aqueous solution to obtain a chitosan solution...

Embodiment 3

[0033] Embodiment three: a kind of preparation method of nano-hydroxyapatite / chitosan, comprises the following processing steps:

[0034] (1) Synthesis of nano-hydroxyapatite: Mix sodium dihydrogen phosphate solution, calcium chloride solution and cetyltrimethylammonium bromide solution (CTAB) to obtain a reaction system, in which Ca 2+ The ion concentration is 10 mmol L -1 , the concentration of phosphate ion is 6 mmol·L -1 , the concentration of CTAB is 9×10 -4 mol L -1 , and the molar ratio of calcium ions to phosphate ions is 5:3; react for 36 hours, and adjust the pH value to maintain at 10; filter the obtained product through a 0.22 μm microporous membrane after centrifugation, and filter to obtain The solid was alternately washed 10 times with water and absolute ethanol, and then dried under vacuum at 50°C overnight to obtain nano-hydroxyapatite powder;

[0035] (2) Dissolve 1g of chitosan powder in 250mL of 2% acetic acid aqueous solution to obtain a chitosan solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com