Preparation method of polyaniline nanotubes

A technology of polyaniline and nanotubes, which is applied in the field of high value-added and high-performance preparation of nanomaterials, can solve problems such as unsatisfactory electrical conductivity, weak product shape control, and heavy metal ion wastewater, so as to achieve abundant reserves and reduce Generation cost, effect of increasing surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

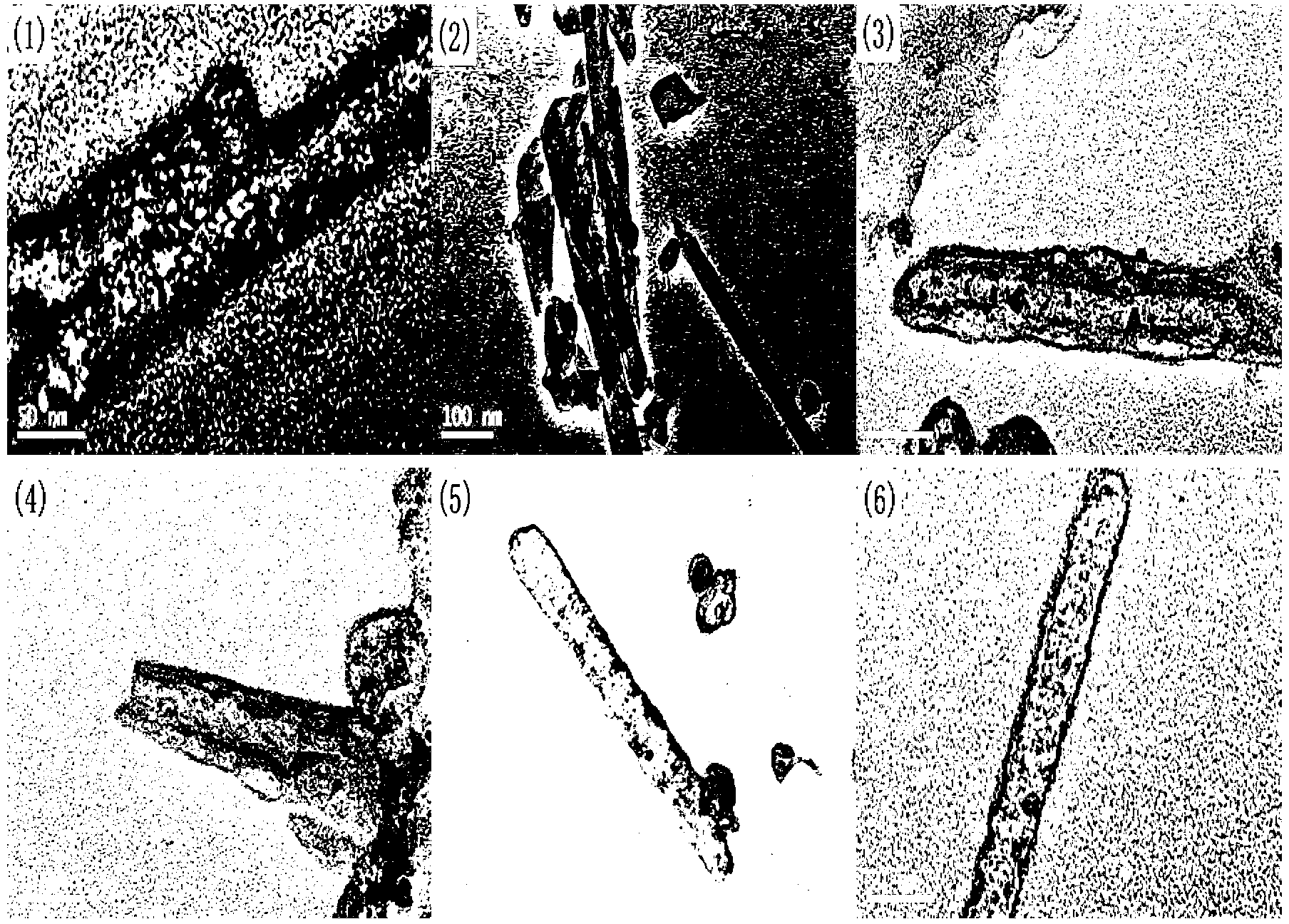

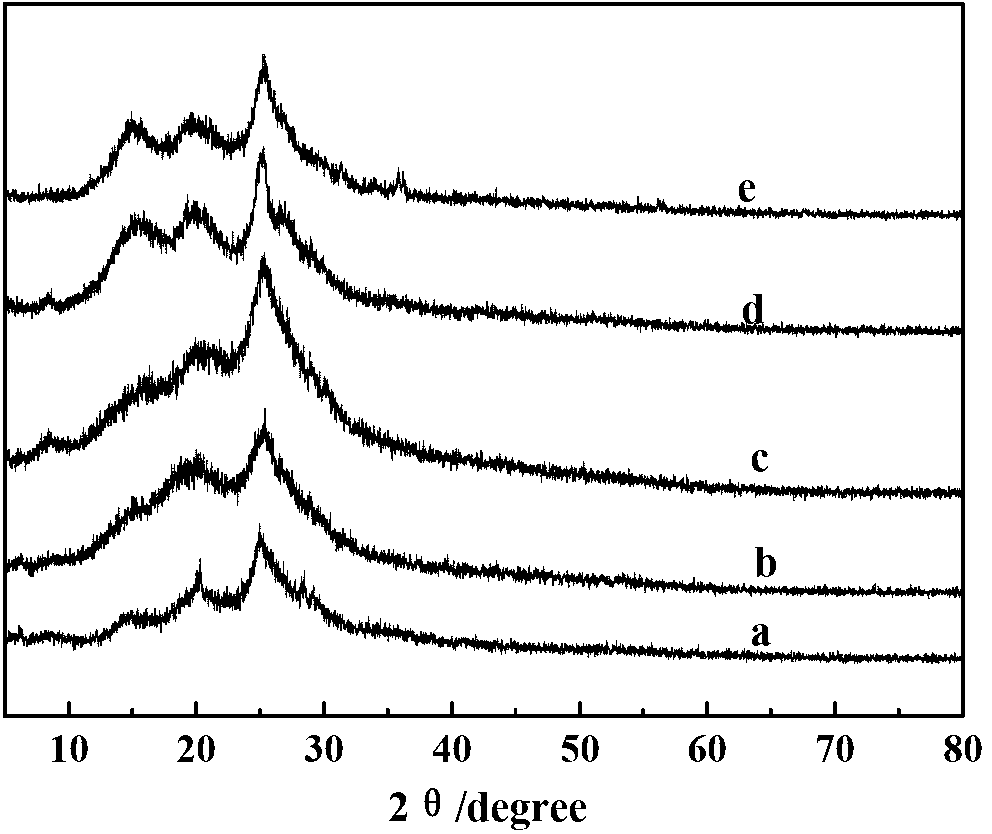

Embodiment 1

[0022] 1. Disperse 5.0 kg of sepiolite in 16.7 kg of deionized water, add 0.25 kg of acrylic acid monomer, add 0.05 kg of ammonium persulfate at a system temperature of 50°C, stir, keep the temperature for 0.5 hours, and keep the system temperature At 0°C, add 1.5 kg of aniline, while stirring, add 8.0 liters of ferric chloride solution with a concentration of 4.0 mol / liter, react for 6 hours, filter with suction, and dry at 90°C to obtain a sepiolite / polyaniline composite material , The measured volume resistivity was 10.0Ω·cm.

[0023] 2. Disperse the composite material prepared in step 1 in a hydrofluoric acid solution with a mass percent concentration of 40% so that the mass ratio of the silicate clay / polyaniline composite material to the acid solution is 0.5, let stand for 1 hour, and pump Filter, wash until the filtrate has a pH value of 3, dry at 60° C., and pulverize to obtain polyaniline nanotubes. The measured volume resistivity is 6.4 Ω·cm.

Embodiment 2

[0025] 1. Disperse 2.0 kg of attapulgite in 40.0 kg of deionized water, add 0.3 kg of methacrylic acid monomer, and add 0.015 kg of ammonium persulfate at a system temperature of 100°C, stir, keep warm for 2 hours, and keep The temperature of the system is 30°C, add 2.0 kg of aniline, and while stirring, add 10.0 liters of potassium dichromate solution with a concentration of 1.0 mol / liter, react for 1 hour, filter with suction, and dry at 50°C to obtain attapulgite / polyaniline Composite material, the measured volume resistivity is 5.7Ω·cm.

[0026] 2. the composite material that step 1 is made is dispersed in the hydrofluoric acid solution that mass percent concentration is 10% so that the mass ratio of silicate clay / polyaniline composite material and acid solution is 1.1, stand for 12 hours, pump Filter, wash until the pH of the filtrate is 5, dry at 80° C., and pulverize to obtain polyaniline nanotubes. The measured volume resistivity is 2.4 Ω·cm.

Embodiment 3

[0028] 1. Disperse 5.0 kg of wollastonite in 25.0 kg of deionized water, add 0.4 kg of methacrylic acid monomer, and add 0.4 kg of ammonium persulfate at a system temperature of 65°C, stir, keep warm for 1.5 hours, and keep The temperature of the system is 20°C, add 4.0 kg of aniline, and while stirring, add 14.3 liters of potassium iodate solution with a concentration of 3.0 mol / liter, react for 4 hours, filter with suction, and dry at 80°C to obtain a wollastonite / polyaniline composite The material has a measured volume resistivity of 4.6Ω·cm.

[0029] 2. The composite material prepared in step 1 is dispersed in a hydrofluoric acid solution with a mass percentage concentration of 30% to make the mass ratio of the silicate clay / polyaniline composite material to the acid solution be 0.8, leave it to stand for 5 hours, and pump Filter, wash until the filtrate has a pH value of 3.5, dry at 70° C., and pulverize to obtain polyaniline nanotubes. The measured volume resistivity is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

| Volume resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com