Semiconductor laser cavity surface passivation film structure and preparation method thereof

A passivation film and laser technology, which is applied in semiconductor lasers, lasers, laser components, etc., can solve the problems of expensive equipment, high equipment requirements, and complicated processes, and achieve simple preparation methods, low dielectric constant, and reduced stress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

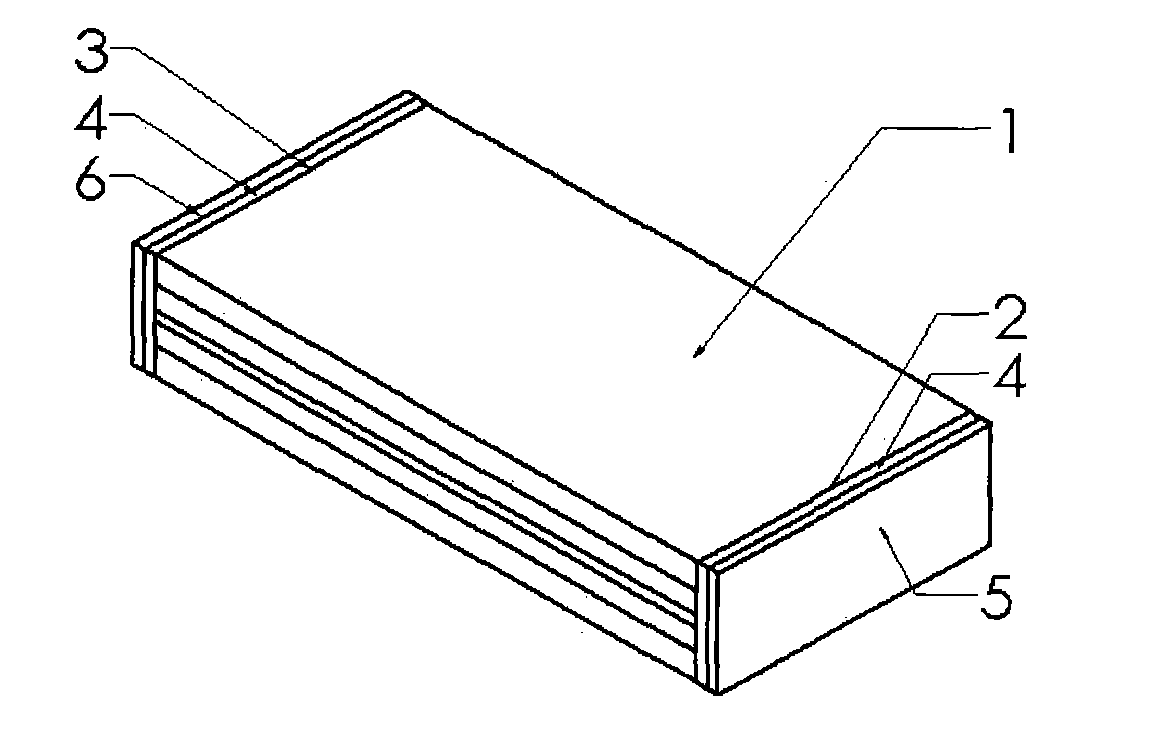

[0020] After the semiconductor laser is cleaved into bar 1 in the air, it is loaded into a special coating fixture, and then put into a magnetron sputtering vacuum chamber.

[0021] Ion pre-cleaning, that is, using low-energy large-beam ions with energy less than 100eV in the magnetron sputtering vacuum chamber to non-destructively remove oxides and impurities on the cavity surface cleaved in air, as well as the surface states and interface states formed by non-radiative recombination. In the center: carry out the ion pre-cleaning on the front cavity surface 2 of the semiconductor laser for 30 seconds to 6 minutes.

[0022] In the high vacuum chamber of the magnetron sputtering system, the background vacuum is 3*10 -9 Torr, the deposition pressure is 16~20mTorr, h-BN is used as the target material, the substrate is equipped with a high-frequency AC power bias device to control the bombardment of the particles on the substrate, the substrate bias is -10~-120V; the RF power is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com