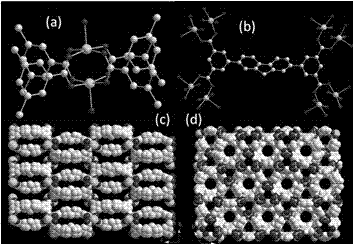

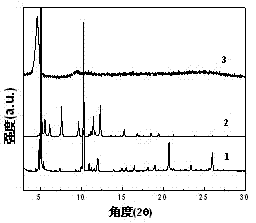

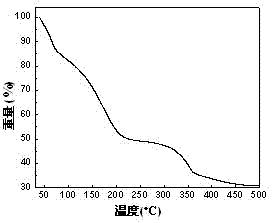

Microporous transition-group metal organic framework material, and preparation and application methods thereof

A technology of metal-organic frameworks and transition metals, applied in the field of microporous transition metal-organic framework materials and their preparation and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of microporous metal-organic framework materials:

[0035] (1) Dissolve 10g of 5-amino-dimethylisophthalate into 225mL of 15% hydrobromic acid solution, stir rapidly and cool to 0℃ . Slowly add 22.5 mL of an aqueous solution of sodium nitrite with a molar concentration of 2.5 mol / L to carry out the diazotization reaction, and continue the reaction for 30 minutes after the addition is complete to obtain a diazonium salt solution;

[0036] (2) Dissolve 9.8g of cuprous bromide into 90mL of hydrobromic acid solution with a mass concentration of 15%, cool to 0°C, and slowly add the diazonium salt obtained in step (1) dropwise to the solution while stirring solution, react at 0°C for 20 minutes, then react at room temperature 8 hours, after the reaction was over, the organic layer was separated by filtration and washed 5 times with water, then the organic layer was dissolved in dichloromethane and washed with anhydrous MgSO 4 Dry, filter and spin-dry the solven...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com