Material used for improving performances of high-temperature resistant, abrasion and antifriction of surface of titanium alloy and application thereof

A high-temperature wear-resistant, titanium alloy technology, applied in metal material coating process, coating and other directions, can solve the problems of surface hardness and high-temperature wear resistance of a single titanium alloy, the coating is easy to peel off, and it does not reduce friction. Achieve the effects of excellent macroscopic mechanical properties, dense coating structure and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1. Mix the powder according to the following weight percentage: nickel (Ni): 15%, chromium (Cr): 12%, chromium carbide (Cr 3 C 2 ): 43%, tungsten disulfide (WS 2 ): 30%. The alloy powder mixture is obtained by mechanical mixing, and the powder particle size reaches 200-300 mesh.

[0025] 2. Dissolving methyl cellulose in ether as a binder, blending with the powder mixture, coating on the surface of titanium alloy (Ti-6Al-4V) to form a coating, and baking to dry.

[0026] 3. Irradiate the pre-laying coating with a laser with a power of 1.5 kW, while blowing inert gas to the molten pool to avoid oxidation of the surface of the molten pool; the laser uses CO 2 Laser, the rectangular spot size is 6 mm × 3 mm, and the laser scanning speed is 4 mm / s.

[0027] 4. According to the size of the titanium alloy (Ti-6Al-4V) substrate, a continuous coating can be obtained by single-pass laser scanning or multi-pass laser scanning.

Embodiment 2

[0029] 1. Mix the powder according to the following weight percentage: nickel (Ni): 15%, chromium (Cr): 12%, chromium carbide (Cr 3 C 2 ): 43%, tungsten disulfide (WS 2 ): 30%. The alloy powder mixture is obtained by mechanical mixing, and the powder particle size reaches 200-300 mesh.

[0030] 2. Use ethanol to dissolve 2123 phenolic resin material as an adhesive. The 2123 phenolic resin is a solid phenolic resin formed by polycondensation of phenol and formaldehyde under the action of an acidic catalyst. Blend the adhesive with the powder mixture, apply it on the surface of the titanium alloy (Ti-6Al-4V) as a coating, and bake it to dry.

[0031] 3. Irradiate the pre-laying coating with a laser with a power of 1.5 kW, while blowing inert gas to the molten pool to avoid oxidation of the surface of the molten pool; the laser uses CO 2 Laser, the rectangular spot size is 6 mm × 3 mm, and the laser scanning speed is 4 mm / s.

[0032] 4. According to the size of the titanium ...

Embodiment 3

[0034] 1. Mix the powder according to the following weight percentage: nickel (Ni): 15%, chromium (Cr): 12%, chromium carbide (Cr 3 C 2 ): 43%, tungsten disulfide (WS 2 ): 30%. The alloy powder mixture is obtained by mechanical mixing, and the powder particle size reaches 200-300 mesh.

[0035] 2. Use ether to dissolve methyl cellulose as a binder, blend it with the powder mixture, apply it on the surface of titanium alloy (Ti-6Al-4V) to form a coating, and bake it to dry.

[0036]3. Irradiate the pre-laying coating with a laser with a power of 1.5 kW, while blowing inert gas to the molten pool to avoid oxidation of the surface of the molten pool; the laser uses CO 2 Laser, the circular spot diameter is 3 mm, and the laser scanning speed is 4 mm / s.

[0037] 4. According to the size of the titanium alloy (Ti-6Al-4V) substrate, a continuous coating can be obtained by single-pass laser scanning or multi-pass laser scanning.

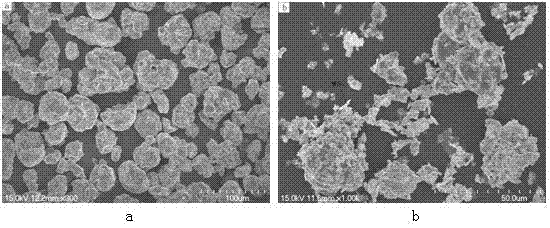

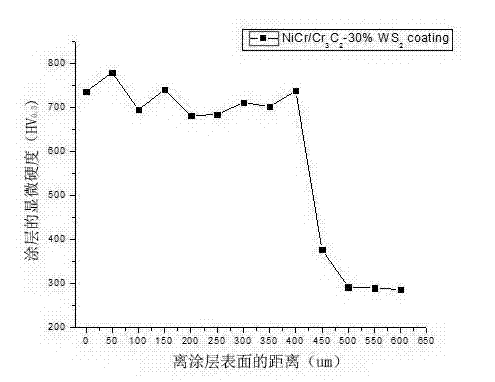

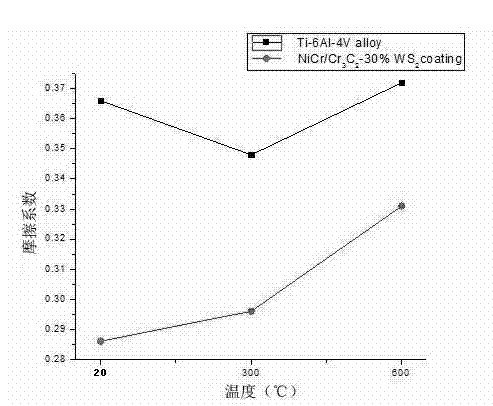

[0038] See attached figure 1 , it is NiCr / Cr 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com