Composite light brick manufactured by utilizing municipal solid waste incinerated ash and preparation method thereof

A technology of municipal solid waste and incineration ash, which is applied in the field of building materials, can solve the problems of poor waterproof and impermeability, easy cracking, etc., and achieve the effects of good cracking resistance, high cleanliness and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

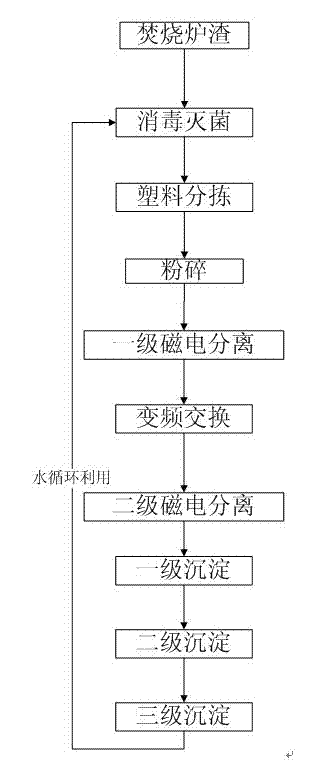

Method used

Image

Examples

Embodiment 1

[0035] The composite lightweight brick manufactured by using municipal solid waste incineration ash in this embodiment has the following composition in terms of mass percentage:

[0036] 60% of bottom ash of municipal solid waste incineration;

[0037] Cement 8%;

[0038] Expanded perlite 7%;

[0039] Additive 5%;

[0040] Filling 20%;

[0041] The composition of the additive in mass percentage is as follows:

[0042] Triethanolamine 1%;

[0045] Polyethylene fiber 2%.

[0046] The filler is composed of sand, lime and fly ash, and the municipal solid waste incineration ash is a ash material obtained after comprehensive treatment to remove heavy metals and harmful substances.

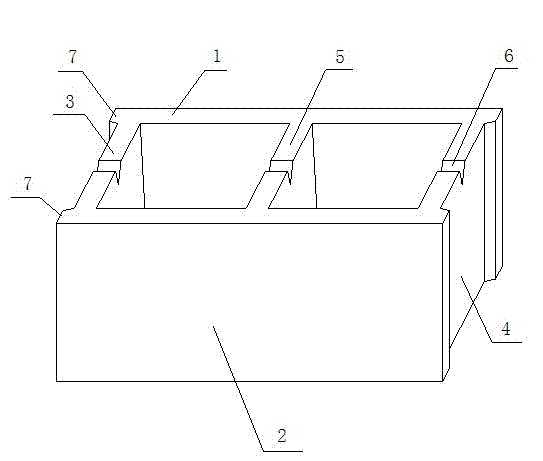

[0047] In this embodiment, the composite lightweight brick is set to a rectangular parallelepiped or cubic structure, and at least one surface is provided with a composite surface layer, a paint layer or a colored layer. The composite surface layer is generally mad...

Embodiment 2

[0051] The difference between this embodiment and the first embodiment lies in the ratio of each component. Specifically, the composite lightweight brick manufactured by using municipal solid waste incineration ash in this embodiment has the following composition by mass percentage:

[0052] Municipal solid waste incineration bottom ash or dried sewage plant sludge 70%;

[0053] Cement 8%;

[0054] Expanded perlite 7%;

[0055] Additive 3%;

[0056] Filling 12%;

[0057] The composition of the additive in mass percentage is as follows:

[0058] 0.8% triethanolamine;

[0060] Sodium nitrite 1%;

[0061] Polyethylene fiber 1%.

Embodiment 3

[0063] The difference between this embodiment and Embodiment 1 and Embodiment 2 lies in the ratio of each component. Specifically, the composite lightweight brick manufactured by using municipal solid waste incineration ash in this embodiment has the following composition by mass percentage :

[0064] 80% of municipal solid waste incineration bottom ash or dry sewage plant sludge;

[0065] Cement 5%;

[0066] Expanded perlite 5%;

[0067] Additive 4%;

[0068] Filling 6%;

[0069] The composition of the additive in mass percentage is as follows:

[0070] Triethanolamine 1%;

[0071] Sodium chloride 0.5%;

[0072] Sodium nitrite 1%;

[0073] 1.5% polyethylene fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com