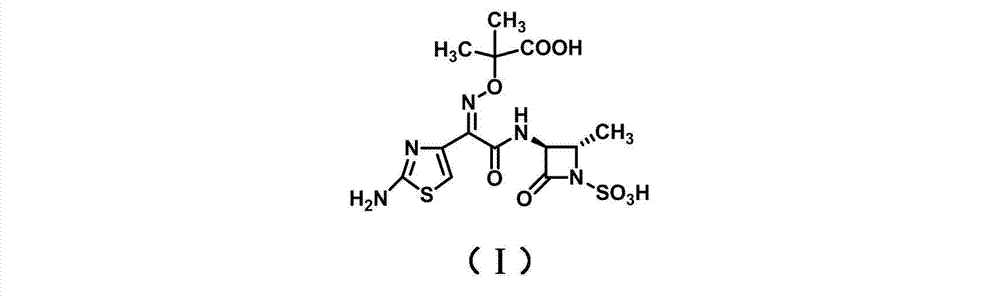

Synthesis method for aztreonam

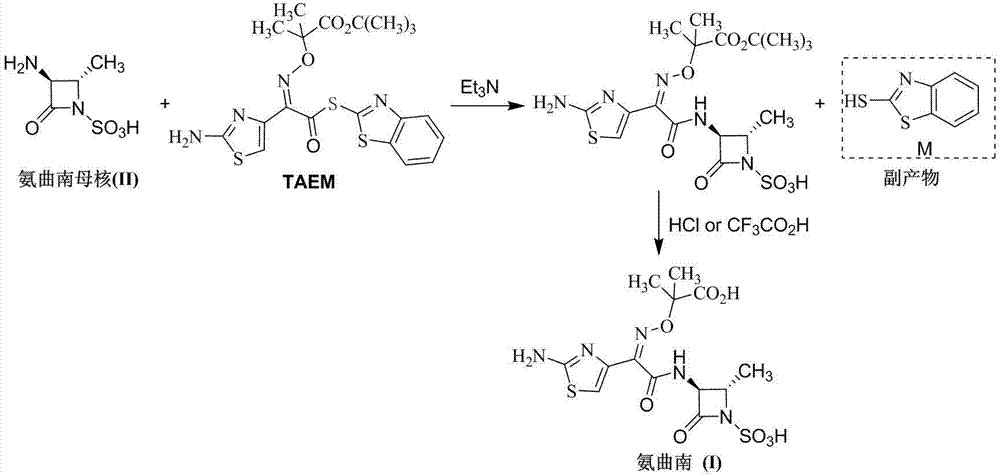

A synthetic method, the technology of aztreonam, applied in the direction of organic chemistry, etc., can solve the problems of difficult removal of by-product M, large environmental pollution, difficult disposal of waste liquid, etc., to achieve improved yield and purity, good atom economy, The effect of reducing the amount of waste acid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

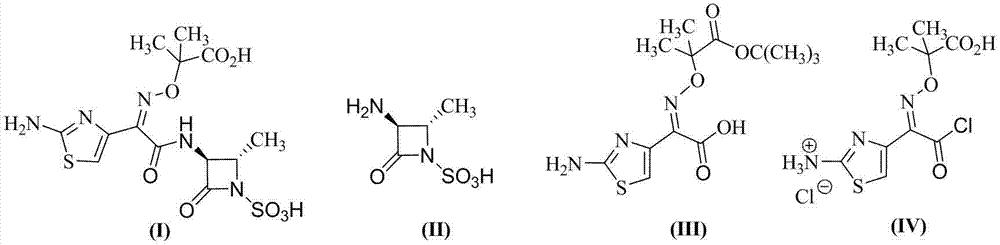

Examples

Embodiment 1

[0028] In a 500mL three-necked flask, add 50.7g (0.182mol) of triphenylphosphine oxide (TPPO), 100g of dichloromethane, and add 18.1g (0.061mol) of bis(trichloromethyl)carbonate (BTC ) and 50g of dichloromethane, after the dropwise addition, keep warm for 2 hours to prepare a solution containing dichlorotriphenylphosphine.

Embodiment 2

[0030]In a 500mL three-necked flask, add 50.7g (0.182 mol) triphenylphosphine oxide (TPPO), 100g 1,2-dichloroethane, dropwise add 18.1g (0.061 mol) bis(trichloromethyl ) Carbonate (BTC) and 50g of 1,2-dichloroethane solution, after the dropwise addition, keep warm for 2 hours to prepare a solution containing dichlorotriphenylphosphine.

[0031] (2) 2-[[(Z)-1-(2-amino-4-thiazolyl)-2-chloro-2-oxoethylene]amino]oxy-2-methylpropion hydrochloride ( IV) Preparation

Embodiment 3

[0033] In a 1L four-neck flask, add 50.0g (0.152 mol) of compound (III) and 50g of dichloromethane, and add the dichlorotriphenylphosphine solution prepared in Example 1 dropwise at -15°C, and keep the reaction for 3 hours. Raise the temperature to 0°C, inject HCl gas to saturation, and keep stirring for 1 h. Add 400g of petroleum ether and stir for 30min. After suction filtration, the filter cake was vacuum-dried to obtain 45.4 g of compound (IV), with a yield of 82.3%. The mother liquor was evaporated to remove the solvent, and the solid was recrystallized from 300 g of toluene to recover 46.4 g of triphenylphosphine oxide, with a recovery rate of 91.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com