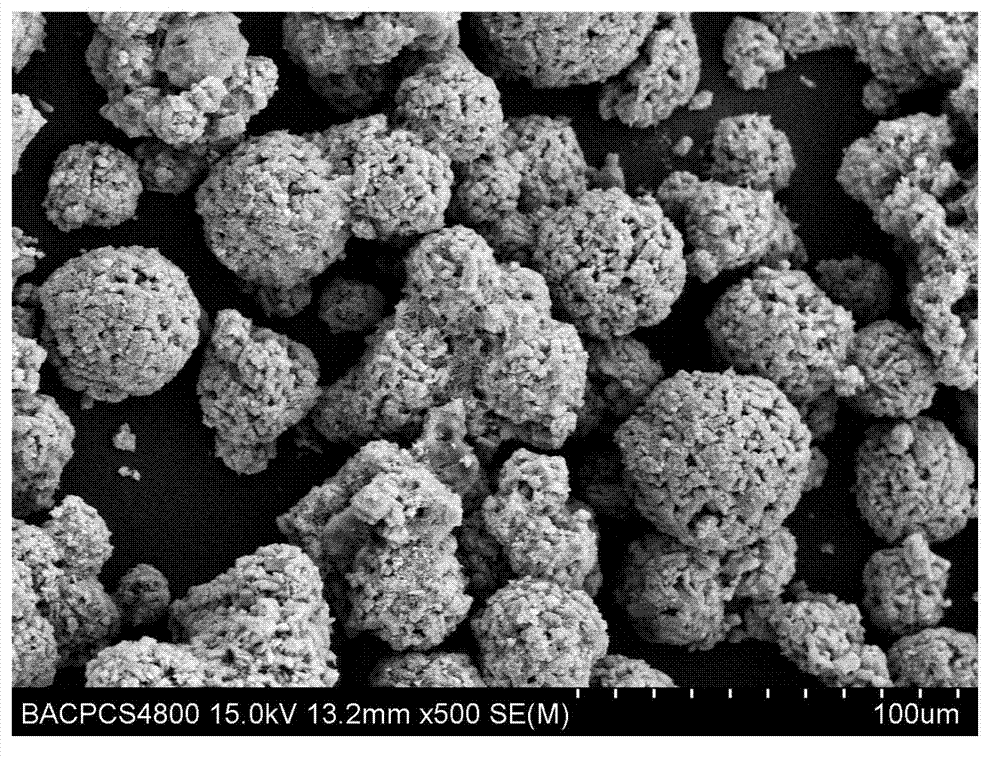

Preparation method for spherical LiMnPO4 anode material

A technology of lithium manganese phosphate, cathode material, applied in chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve the problems of limited phase purity, high energy consumption, poor product performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] 1) The three raw materials of manganese acetate, phosphoric acid and lithium hydroxide according to Mn: Li: PO 4 =1:1:1 molar ratio is added to deionized water, wherein the molar concentration of Mn in the mixed solution is 1mol / L, stirred to make it evenly mixed.

[0019] 2) Adding 8% sucrose in mass ratio as an organic carbon source to the obtained mixed liquid, stirring to make it evenly mixed.

[0020] 3) The obtained mixed liquid is sprayed and pyrolyzed through a spray dryer, and the inlet temperature is controlled to be 220° C., and the outlet temperature is 120° C. to obtain a lithium manganese phosphate precursor powder uniformly mixed with materials.

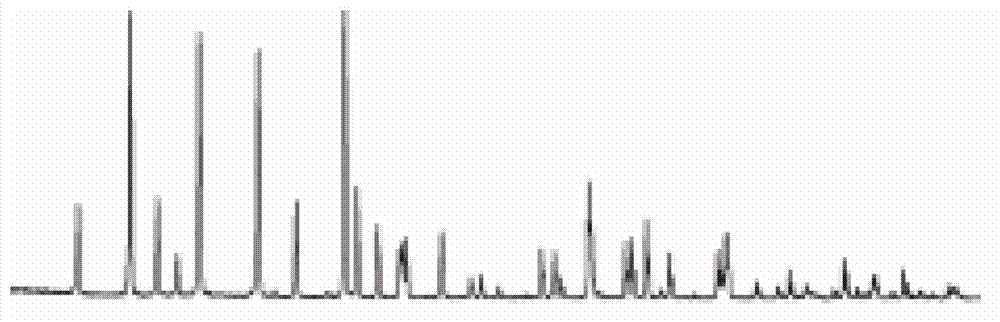

[0021] 4) The obtained lithium manganese phosphate precursor powder was put into a crucible, placed in a microwave sintering furnace, and heated at 1 kW for 3 hours to obtain a spherical lithium manganese phosphate positive electrode material with good crystallinity and uniform phase.

[0022] The present inven...

Embodiment 2

[0024] 1) The three raw materials of manganese acetate, phosphoric acid and lithium hydroxide according to Mn: Li: PO 4 =1:1:1 molar ratio is added to deionized water, wherein the molar concentration of Mn in the mixed solution is 1mol / L, stirred to make it evenly mixed.

[0025] 2) Adding 10% sucrose by mass ratio as an organic carbon source to the obtained mixed liquid, stirring to make it evenly mixed.

[0026] 3) Spray pyrolyze the obtained mixed solution through a spray dryer (control the inlet temperature at 220° C. and the outlet temperature at 120° C.) to obtain lithium manganese phosphate precursor powder uniformly mixed with materials.

[0027] 4) The obtained lithium manganese phosphate precursor powder was put into a crucible, placed in a microwave sintering furnace, and heated at 2 kW for 2 hours to obtain a spherical lithium manganese phosphate positive electrode material with good crystallinity and uniform phase.

Embodiment 3

[0029] 1) The three raw materials of manganese acetate, phosphoric acid and lithium hydroxide according to Mn: Li: PO 4 =1:1:1 molar ratio is added to deionized water, wherein the molar concentration of Mn in the mixed solution is 1mol / L, stirred to make it evenly mixed.

[0030] 2) Adding 12% sucrose by mass ratio as an organic carbon source to the obtained mixed liquid, stirring to make it evenly mixed.

[0031] 3) Spray pyrolyze the obtained mixed solution through a spray dryer (control the inlet temperature at 220° C. and the outlet temperature at 120° C.) to obtain lithium manganese phosphate precursor powder uniformly mixed with materials.

[0032] 4) The obtained lithium manganese phosphate precursor powder was put into a crucible, placed in a microwave sintering furnace, and heated at 3 kW for 1 hour to obtain a spherical lithium manganese phosphate positive electrode material with good crystallinity and uniform phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com