Method of glycerolysis reaction for preparing partial glyceride

A partial glyceride and glycerol hydrolysis technology, applied in the field of oil production rich in partial glyceride, can solve problems such as increasing cost, and achieve the effects of avoiding hydrolysis, simplifying recovery and high thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

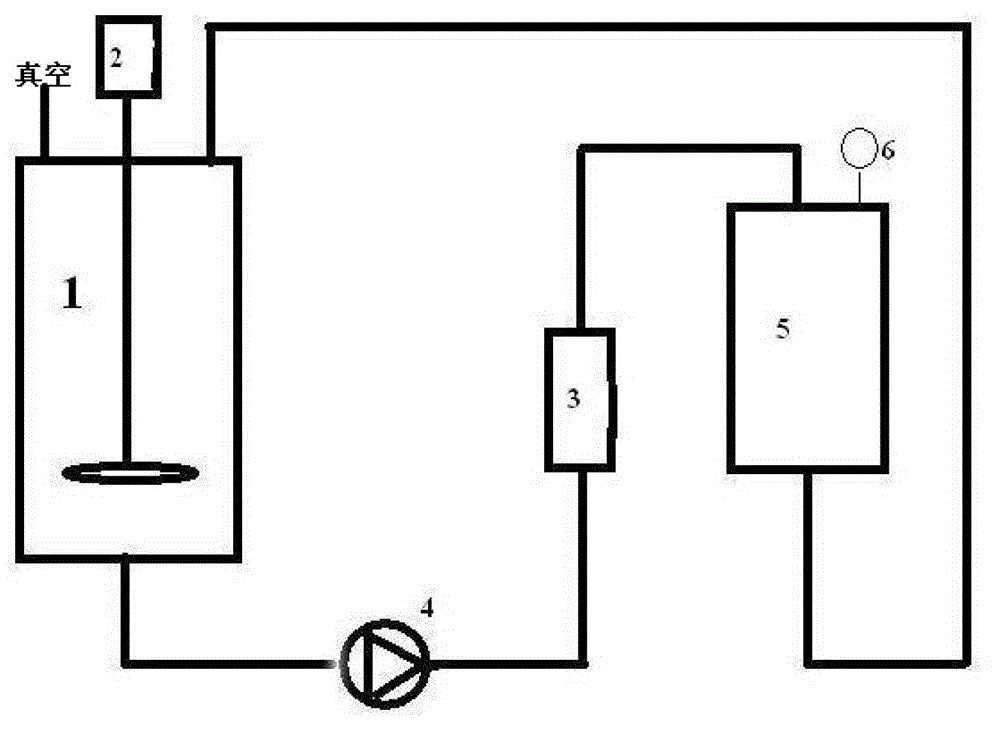

[0024] Get 500g of activated macroporous weakly polar adsorption resin AB-8, 1000g of Tris-HCl buffer (concentration 0.05mol / L, pH8.8), 20g of free lipase Lipase T1 (Leow TC, RahmanRNZRA, Basri M, Salleh AB. High level expression of thermostable lipase from Geobacillus sp.strain T1[J]. Bioscience, biotechnology, and biochemistry 2004; 68(1): 96-103.) mixed, stirred and adsorbed at 30°C for 1 hour, It was then filtered and vacuum-dried to a moisture content of 0.5% to obtain lipase T1 immobilized on a macroporous adsorption resin, which was stored in a refrigerator at 4°C for later use. 9Kg refined soybean oil and 1Kg glycerin are added in raw material tank 1, and the moisture content in the control reaction system is no more than 0.1%, under the situation of magnetic stirring, as figure 1As shown, the reactant is transported by the pump 4 and flows through the enzyme reactor 5 and then returns to the raw material tank 1. The amount of immobilized lipase LipaseT1 is 300 g, the ...

Embodiment 2

[0026] Take 500g of activated macroporous weakly polar adsorption resin AB-8, 1000g of Tris-HCl buffer solution (concentration 0.05mol / L, pH8.8), 20g of free lipase Lipase T1, mix, and stir at 30°C Adsorbed for 1 hour, then filtered, and vacuum-dried to a moisture content of 0.5% to obtain lipase T1 immobilized on a macroporous adsorption resin, which was stored in a refrigerator at 4°C for later use. 9Kg refined soybean oil and 1.84Kg glycerol are added in raw material tank 1, and the moisture content in the control reaction system is no more than 0.1%, under the situation of magnetic stirring, as figure 1 As shown, the reactant is transported by the pump 4 and flows through the enzyme reactor 5 and then returns to the raw material tank 1. The amount of immobilized lipase LipaseT1 is 300 g, the reaction temperature is 80 ° C, and the entire reaction system is placed in a vacuum state with a pressure of 50 Pa. After 6 hours, the reaction was stopped, and the reaction product w...

Embodiment 3

[0028] Take 5Kg of activated macroporous weakly polar adsorption resin AB-8, 10Kg of Tris-HCl buffer (concentration 0.05mol / L, pH8.8), 100g of free lipase Lipase T1, mix and stir at 25°C Adsorbed for 1 hour, then filtered, and vacuum-dried to a moisture content of 0.6% to obtain lipase T1 immobilized on a macroporous adsorption resin, which was stored in a 4°C refrigerator for later use. 90Kg refined soybean oil and 18.4Kg glycerin are added in raw material tank 1, and the moisture content in the control reaction system is no more than 0.1%, under the situation of magnetic stirring, as figure 1 As shown, the reactants are pumped and flowed through the enzyme reactor and then returned to the raw material tank 1. The amount of immobilized lipase LipaseT1 is 3Kg, the reaction temperature is 80°C, and the entire reaction system is placed under a vacuum state of 50Pa. After 6 hours, the reaction was stopped, and the reaction product was centrifuged to get the upper oil phase for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com