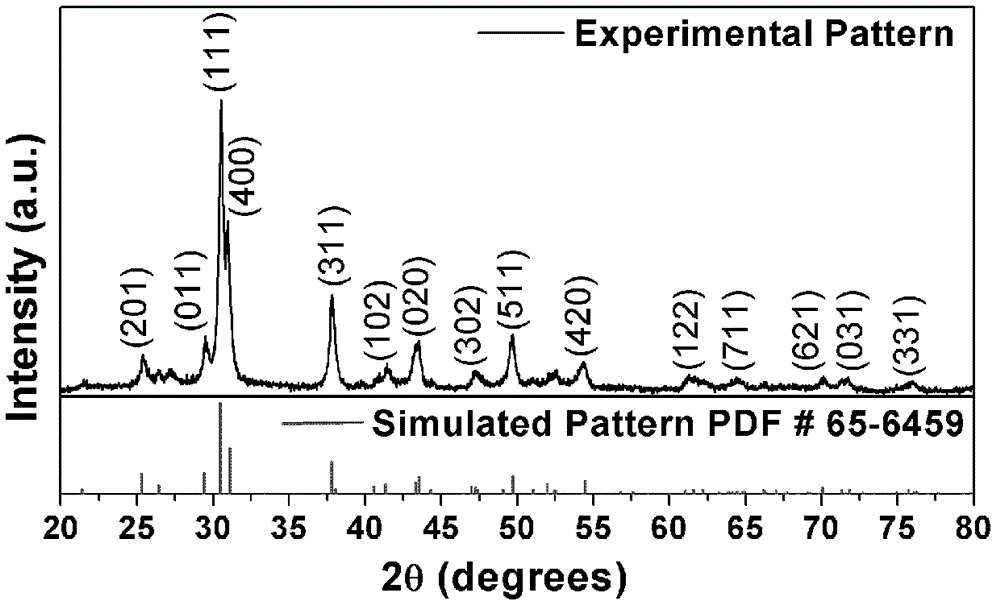

Solution phase method for synthesizing tin selenide monocrystal nanowire

A technology of single crystal nanometer and tin selenide, which is applied in the direction of chemical instruments and methods, single crystal growth, single crystal growth, etc., can solve the problem of small diameter of colloidal products, achieve uniform shape, good colloidal dispersion, The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

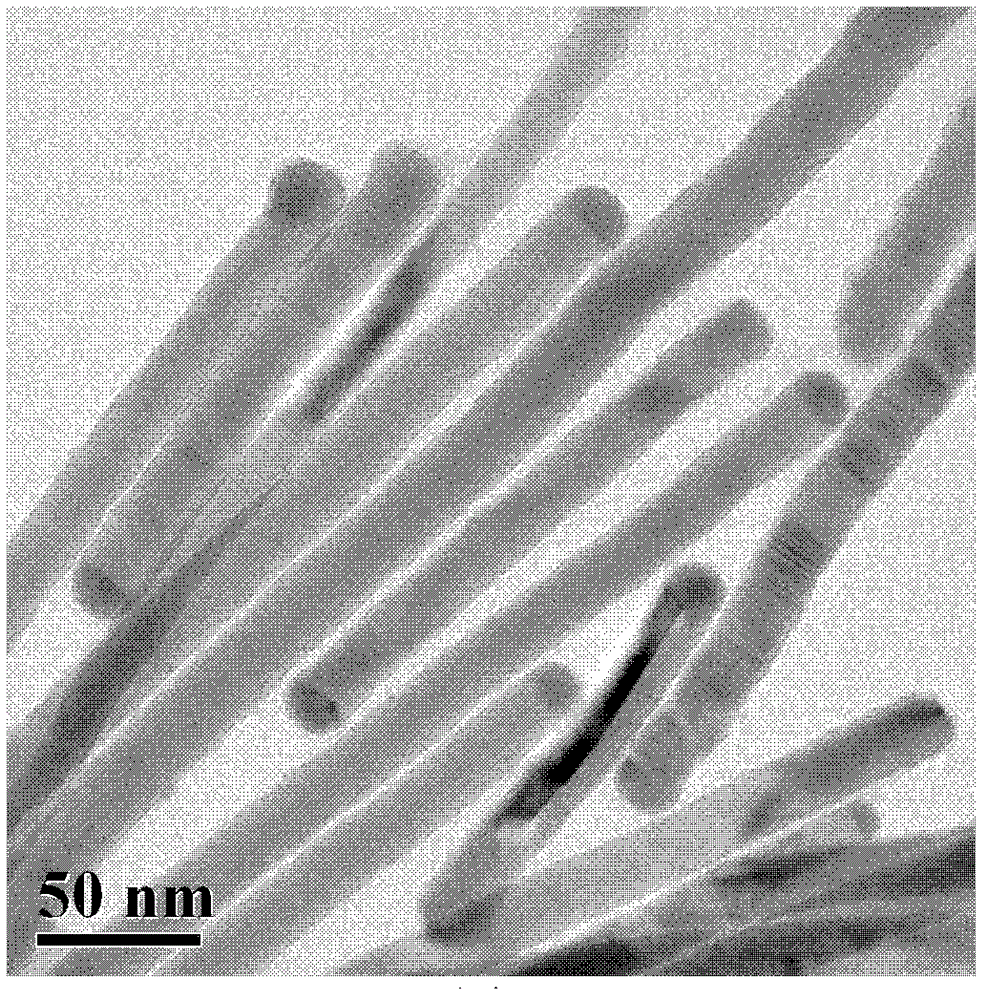

Embodiment 1

[0031] Mix 2.5mmol Se powder and 10mmol TOP, and magnetically stir at room temperature for 10 hours to completely dissolve Se to obtain a 0.5mol / L Se precursor solution. Mix 0.02mmol BiCl3 with 1.0mL acetone and stir magnetically for 1 minute to obtain a 0.02mol / L BiCl3 solution. Take 200 μL BiCl3 solution and mix with 0.2 mmol bis[bis(trimethylsilyl)amino]tin(II) to obtain Sn injection solution. 400 μL of Se precursor solution was mixed with 4 g of oleylamine to obtain a reaction solution, which was heated to 290° C. under nitrogen protection. The prepared Sn injection solution was added to the above reaction solution, and reacted for 2 minutes to obtain a tin selenide single crystal nanowire with a length of about 1 μm.

Embodiment 2

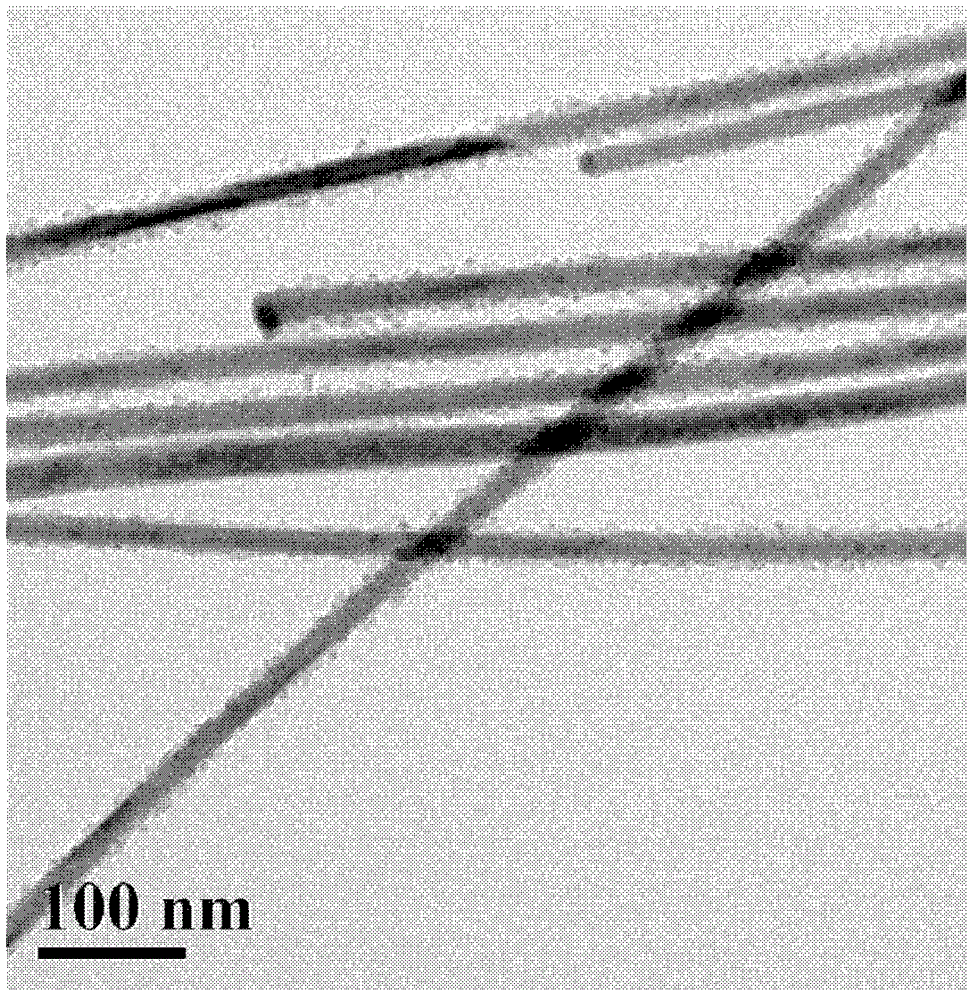

[0033] Mix 2.5mmol Se powder and 10mmol TOP, and magnetically stir at room temperature for 10 hours to completely dissolve Se to obtain a 0.5mol / L Se precursor solution. Mix 0.02mmol BiCl3 with 1.0mL acetone and stir magnetically for 1 minute to obtain a 0.02mol / L BiCl3 solution. Take 200 μL BiCl3 solution and mix with 0.2 mmol bis[bis(trimethylsilyl)amino]tin(II) to obtain Sn injection solution. Take 400 μL of Se precursor solution, mix with 3.5g TOPO and 2.5g oleylamine to obtain a reaction solution, and heat to 290°C under the protection of nitrogen. The prepared Sn injection solution was added to the above reaction solution, and reacted for 2 minutes to obtain a tin selenide single crystal nanowire with a length of about 10 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com