Microsphere tissue engineering scaffold used in beauty filling, and preparation method of microsphere tissue engineering scaffold

A technology of tissue engineering scaffolds and microspheres, which is applied in tissue regeneration, coating, medical science, etc., can solve the problems that cannot be confined to the required position, the fluidity of the microsphere material is large, and the difficulty of taking out the prosthesis, so as to prevent escape. Dispersion, avoiding the formation of granulation tissue, wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

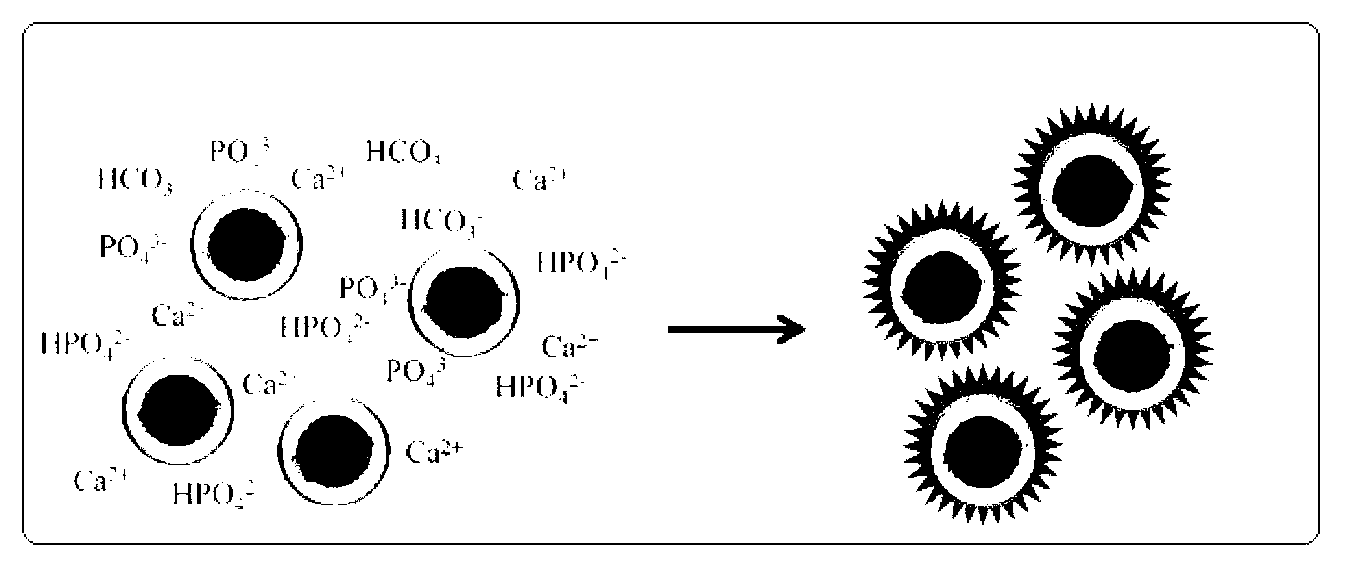

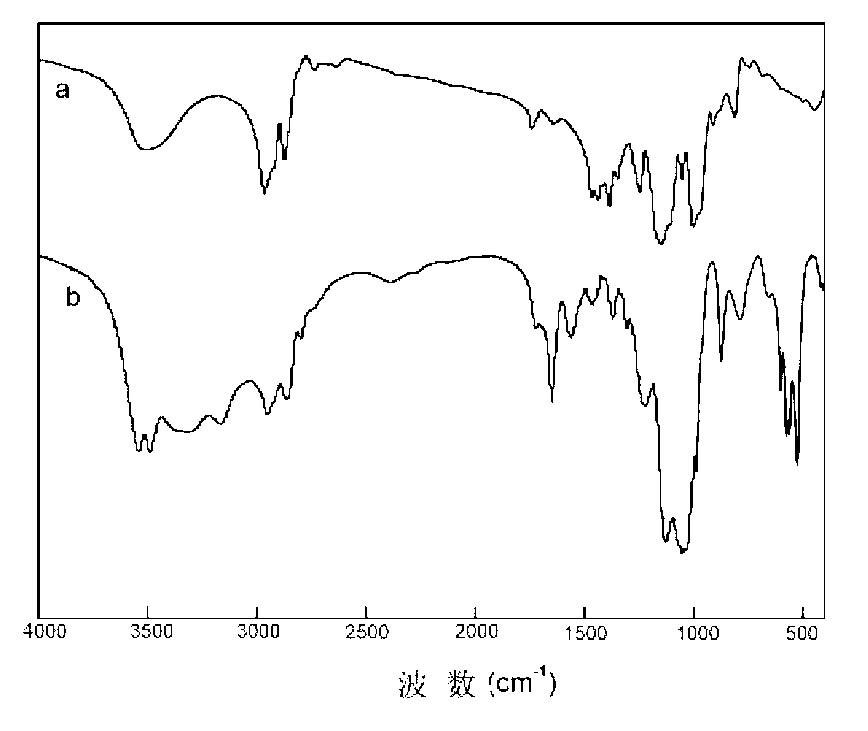

Method used

Image

Examples

Embodiment 1

[0046] In this example, the method of the present invention is used to prepare microsphere tissue engineering scaffolds for cosmetic filling, and the process steps are as follows:

[0047] (1) Preparation of polyurethane microspheres

[0048] ①Prepolymerization reaction

[0049] Add 0.27mol of isophorone diisocyanate and 0.15mol of polyε-caprolactone diol 2000 into a four-neck three-necked bottle equipped with a stirrer, thermometer, condenser, and nitrogen inlet and outlet pipes, and stir at a stirring speed of 1000r / min Under normal pressure, 75°C and under the protection of nitrogen, react for 2.5 hours, and pass condensed water into the condensation pipe during the reaction;

[0050] ② Chain extension reaction

[0051] At a stirring speed of 1000r / min, add 0.07mol of hydrophilic chain extender triethanolamine to the reaction solution formed in step ①, and lower its temperature to room temperature, then add 4 times the molar amount of isophorone diisocyanate Acetone and ...

Embodiment 2

[0060] In this example, the method of the present invention is used to prepare microsphere tissue engineering scaffolds for cosmetic filling, and the process steps are as follows:

[0061] (1) Preparation of polyurethane microspheres

[0062] ①Prepolymerization reaction

[0063] Add 0.26 mol of diphenylmethane diisocyanate and 0.19 mol of polyε-caprolactone diol 1000 into a four-neck three-neck flask equipped with a stirrer, a thermometer, a condenser tube, and a nitrogen inlet and outlet tube, at a stirring speed of 1000r / min Under normal pressure, 75°C and under the protection of nitrogen, react for 3.5 hours, and pass condensed water into the condensation pipe during the reaction;

[0064] ② Chain extension reaction

[0065] At a stirring speed of 1000r / min, add 0.02mol small molecule chain extender ethylene glycol and 0.03mol hydrophilic chain extender 2,2-dimethylolpropionic acid into the reaction solution formed in step ①, and mix them The temperature is lowered to ro...

Embodiment 3

[0074] In this example, the method of the present invention is used to prepare microsphere tissue engineering scaffolds for cosmetic filling, and the process steps are as follows:

[0075] (1) Preparation of polyurethane microspheres

[0076] ①Prepolymerization reaction

[0077] Add 0.27mol of isophorone diisocyanate and 0.15mol of polyε-caprolactone diol 2000 into a four-neck three-necked flask equipped with a stirrer, thermometer, condenser, and nitrogen inlet and outlet pipes, and stir at a stirring speed of 900r / min Under normal pressure, 70°C and under the protection of nitrogen, react for 3 hours, and pass condensed water into the condensation pipe during the reaction;

[0078] ② Chain extension reaction

[0079] At a stirring speed of 900r / min, add 0.07mol of hydrophilic chain extender 2,2-dimethylolpropionic acid to the reaction liquid formed in step ①, and lower its temperature to room temperature, then add isophorone Acetone that is 3 times the molar weight of dii...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com