ZnO-based diluted magnetic semiconductor thin film and preparation method thereof

A technology of dilute magnetic semiconductor and thin film, applied in the field of material science

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] 1) Adjust the pH value of 600mL of 1mol / L ammonium bicarbonate solution to 8.7 with ammonia water with a concentration of 28% by mass to obtain a precipitant, which is heated to 50°C in a water bath;

[0062] 2) Add 475mL of 0.5mol / L Zn(NO 3 ) 2 ·6H 2 Aqueous solution of O and 25 mL of 0.5 mol / L Co(NO 3 ) 2 Mix evenly, add the mixed solution to the precipitant obtained in step 1) with a dropper, and carry out co-precipitation reaction at 50°C for 1 hour to produce a pale pink precipitate, collect the obtained precipitate, filter the precipitate, and dry it to obtain Precursor powder II;

[0063] 3) Calcining the precursor powder II obtained in step 2) at 400°C for 1 hour to obtain ceramic powder, granulating and pressing the ceramic powder with PVA, controlling the heating rate at 3°C / min, and sintering at 1300°C 4h firing ceramic target II;

[0064] 4) Using the ceramic target II obtained in step 3) as the target, deposit a thin film (laser pulse energy 335mJ) on...

Embodiment 2

[0069] 1) With analytically pure zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) and cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 (2) is raw material, and citric acid is complexing agent, is dissolved in 30mL solvent ethylene glycol monomethyl ether, makes its concentration all be 0.2mol / L, stirs at normal temperature for 4 hours to obtain Sol II.

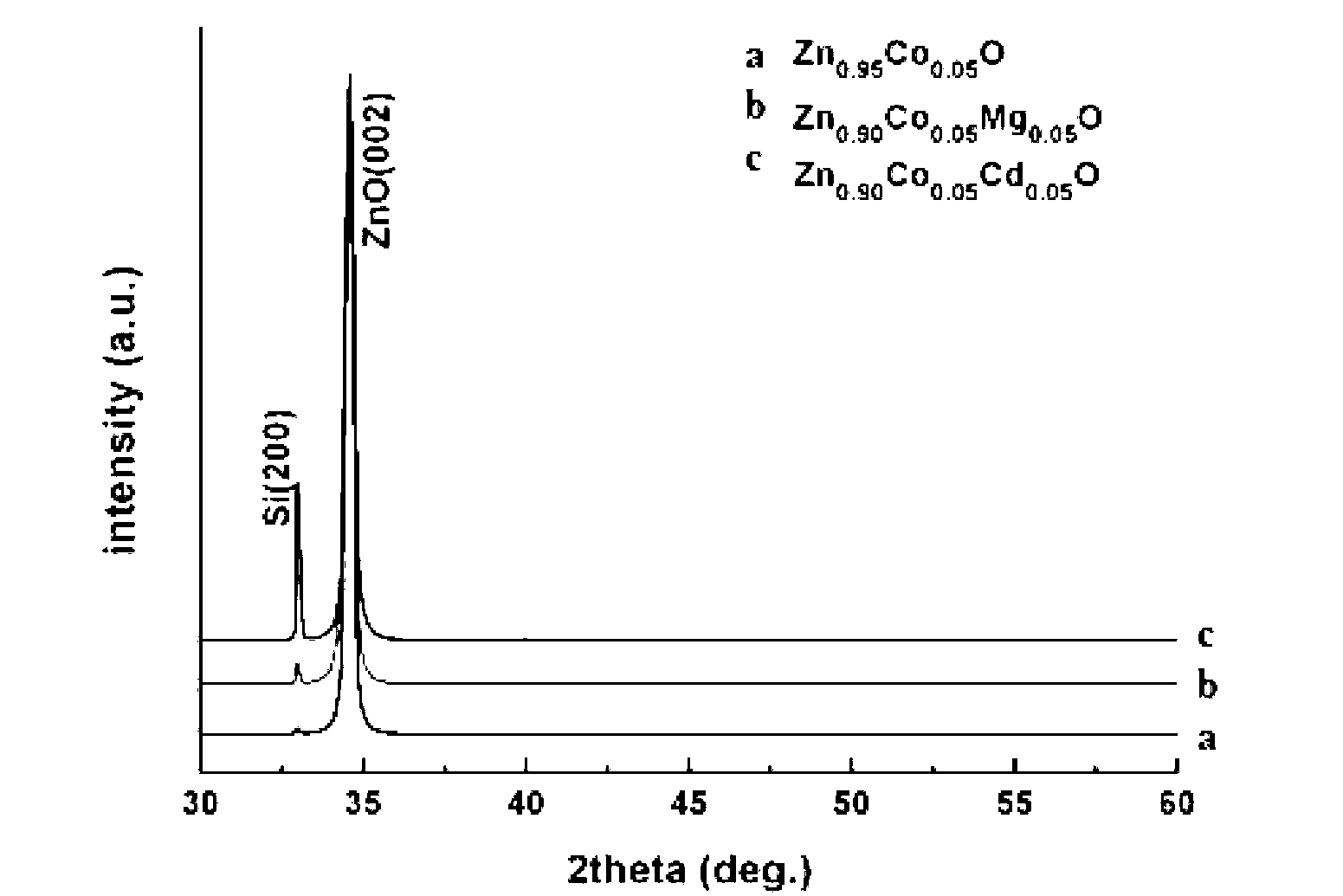

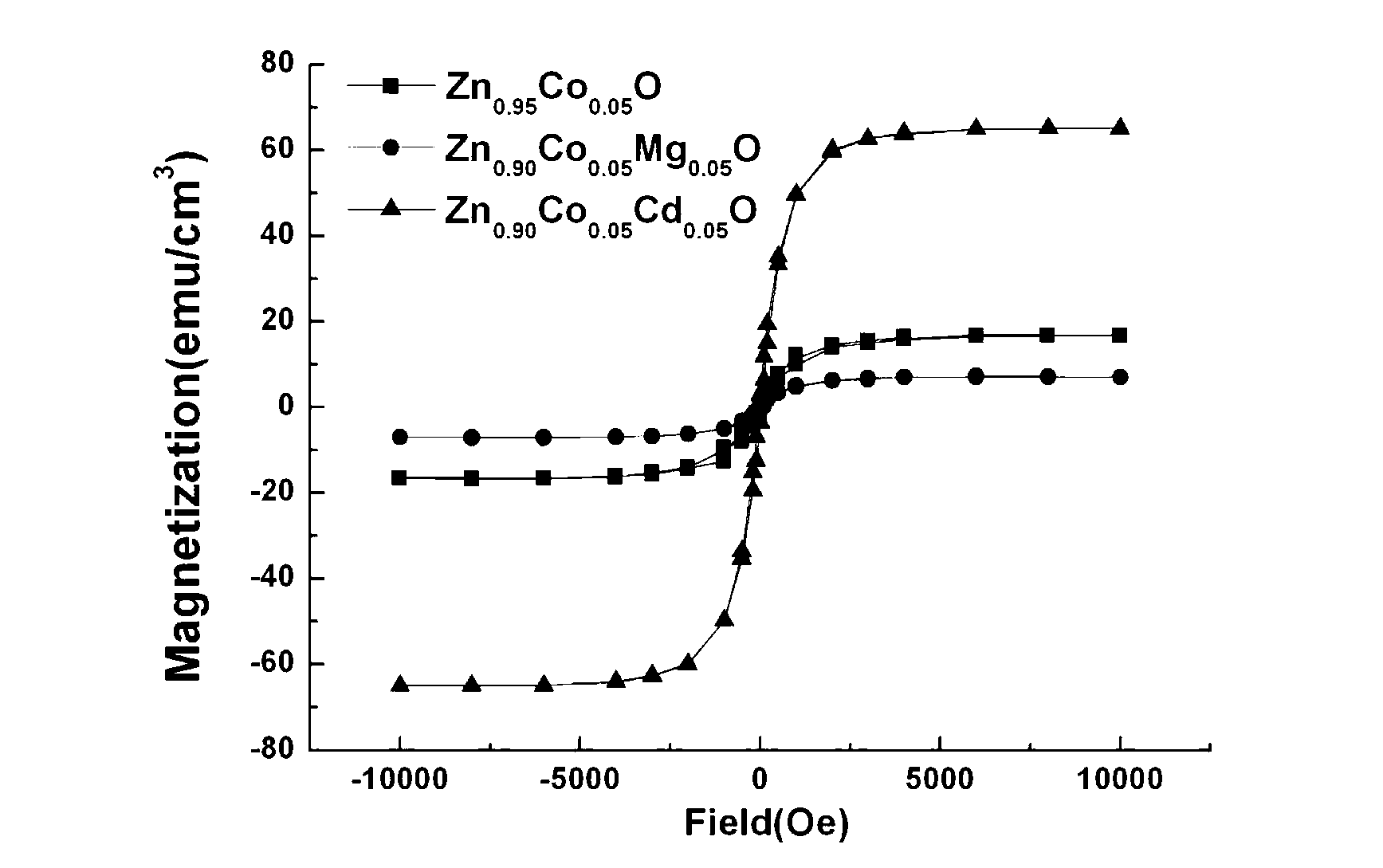

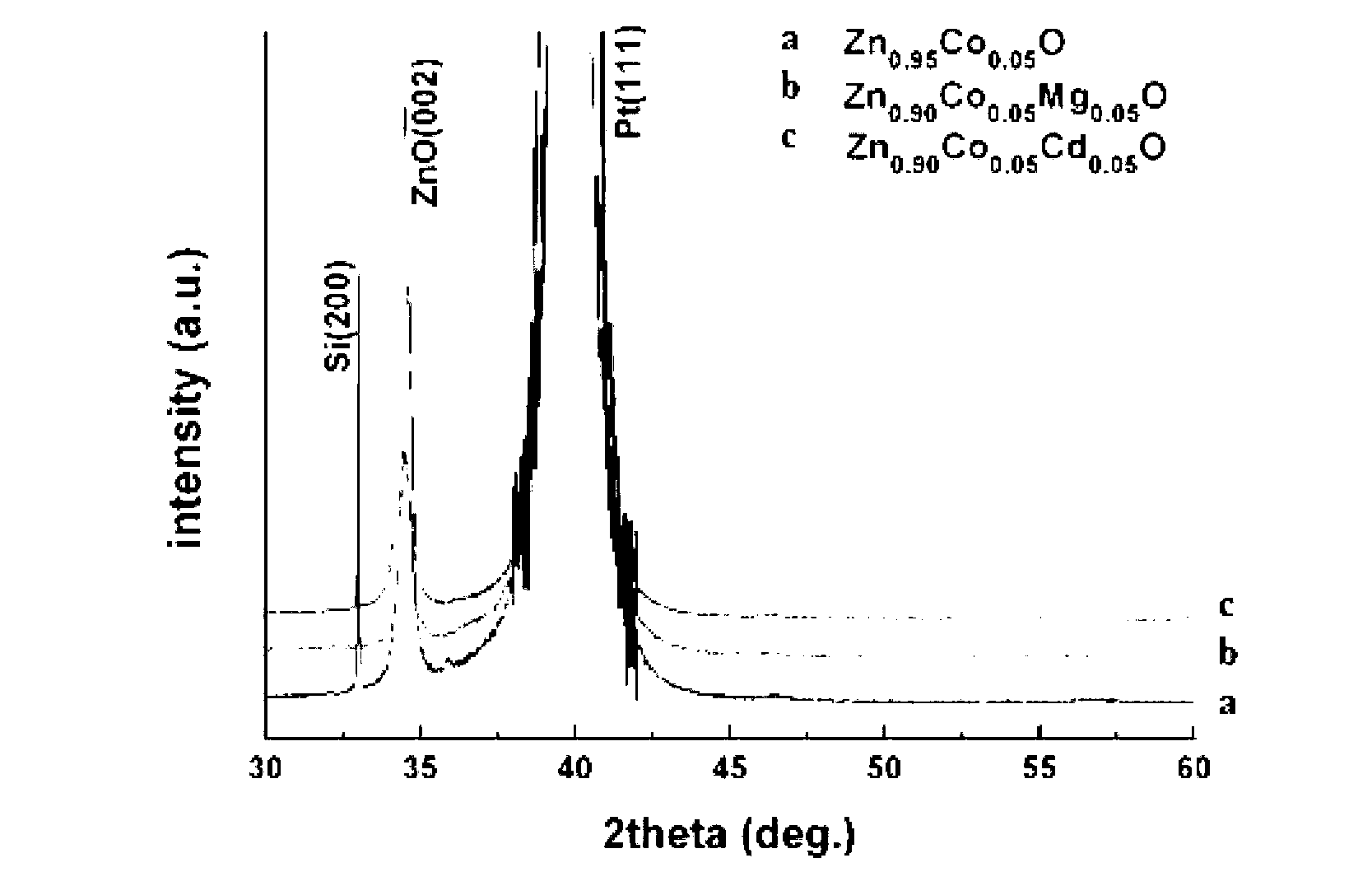

[0070] 2) Use the sol II obtained in step 1) to spin coat a film on a Si(100) / Pt(111) substrate with a rotation speed of 3000rpm and a radius of rotation of 5mm. After heat treatment at 350°C for 5min, repeat the above process until the film reaches the desired thickness , and finally annealed at 600°C for 15 minutes in a rapid heat treatment furnace to obtain a composition of Zn 0.95 co 0.05 O ZnO-based dilute magnetic semiconductor thin films.

[0071] According to the same method as above, only replace the corresponding reactant according to the composition of the product, and before the step 1) dissolving step, add magne...

Embodiment 3

[0074] 1) With analytically pure zinc nitrate hexahydrate (Zn(NO 3 ) 2 ·6H 2 O) and the manganese nitrate aqueous solution that mass percent concentration is 50% is raw material, and citric acid is complexing agent, is dissolved in the 30mL solvent ethylene glycol monomethyl ether, Zn 2+ The concentration of the solution was 0.2mol / L, and it was stirred at room temperature for 4 hours to obtain Sol III.

[0075] 2) Use the sol III obtained in step 1) to spin-coat a film on a Si(100) / Pt(111) substrate with a rotation speed of 3000rpm and a radius of rotation of 5mm. After heat treatment at 350°C for 5min, repeat the above process until the film reaches the desired thickness , and finally annealed at 600°C for 15 minutes in a rapid heat treatment furnace to obtain a composition of Zn 0.95 mn 0.05 O ZnO-based dilute magnetic semiconductor thin films.

[0076] According to the same method as above, only replace the corresponding reactant according to the composition of the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com