Oil-water separation copper foam and preparation method thereof

A technology of oil-water separation and copper foam, which is applied in the field of copper foam, can solve the problems of lack of third-dimensional support and supplement, complicated process methods, and difficulty in large-scale preparation, and achieve excellent oil absorption characteristics, excellent superhydrophobic and superoleophilic properties, and high The effect of thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] A kind of preparation method of efficient oil-water separation copper foam, described method comprises the following steps:

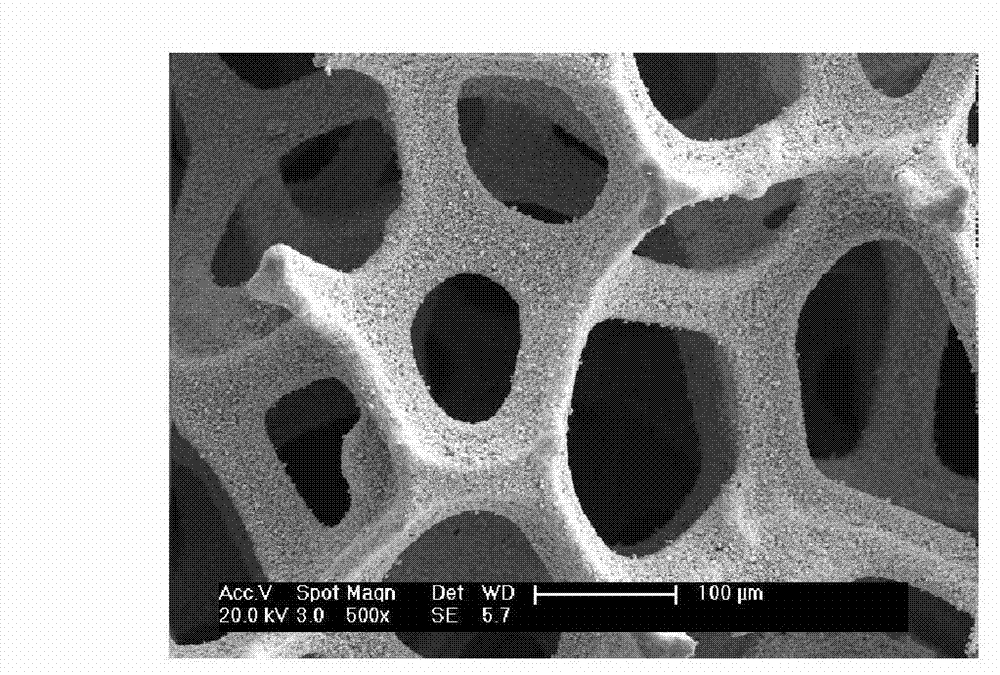

[0027] (1) Foam copper pre-treatment: select three-dimensional through-hole foam copper with a thickness of 1-3mm (prepared by any method, commercially available can be used), the pore size is 400-1500μm, and cut it into the required size (for example, 5cm ×5cm), cleaned with acetone and ethanol in an ultrasonic environment for 5 minutes, blown dry with nitrogen, and then immersed in dilute hydrochloric acid aqueous solution with a molar concentration of 1mol / L for 60s to remove the oxide film on the surface and activate the surface of the foamed copper tendon. After taking it out, wash it successively with 1mol / L dilute sodium hydroxide aqueous solution and deionized water, and dry it with nitrogen;

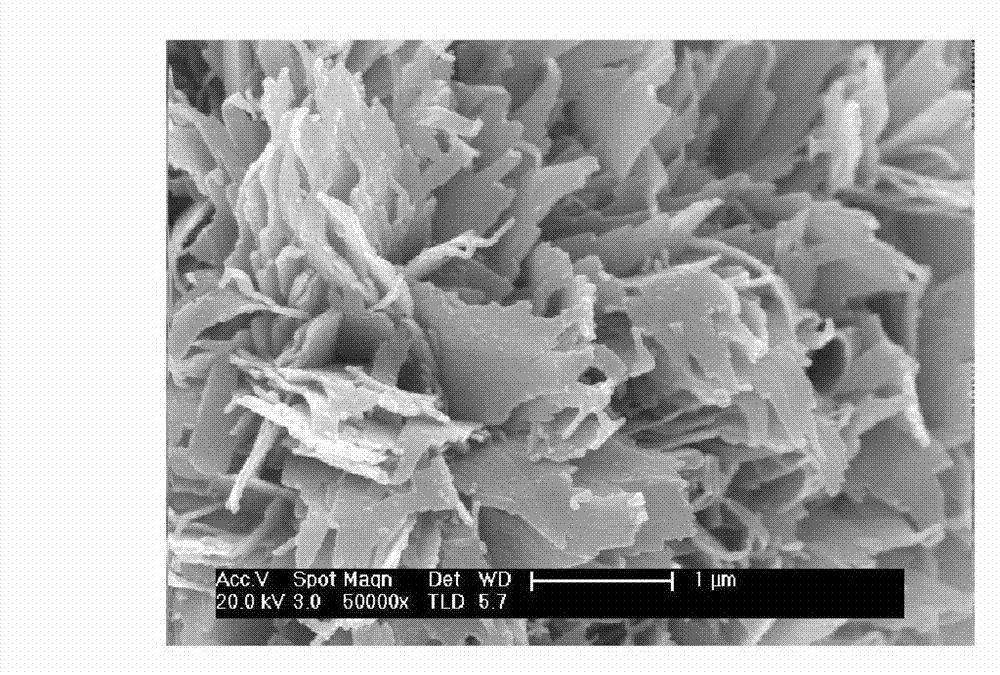

[0028] (2) Surface roughening of activated foamed copper tendons: immerse the treated and activated foamed copper in a closed 0.1-0.5mol / L ammonia...

Embodiment 1

[0031] (1) Select a three-dimensional through-hole copper foam with a thickness of 1mm and a pore size of 400μm, cut it into the required size (5cm×5cm), clean it with acetone and ethanol in an ultrasonic environment for 5min, dry it with nitrogen, and then immerse it in a molar concentration Treat in 1mol / L hydrochloric acid aqueous solution for 60s to remove the oxide film on the surface and activate the surface of foamed copper tendons. After taking it out, wash it with 1mol / L sodium hydroxide aqueous solution and deionized water successively, and dry it with nitrogen gas;

[0032] (2) Immerse the activated copper foam in a closed 0.1mol / L ammonia solution for 12 hours, take it out, rinse it with clean water and dry it; put the ammonia solution in a closed container, heat it in a water bath, and the temperature is 5°C;

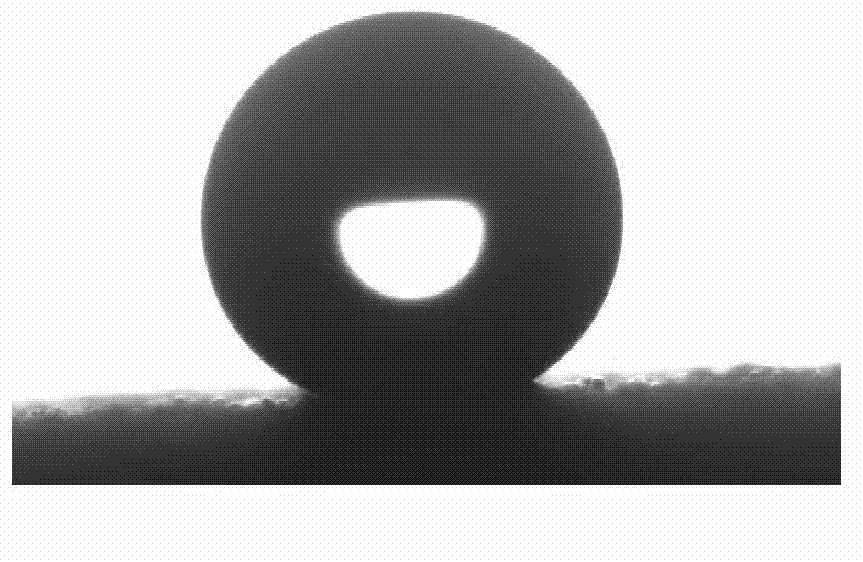

[0033](3) Soak the copper foam that has been activated and roughened in the stearic acid modification solution, soak it in a water bath at 80°C for 30 minut...

Embodiment 2

[0036] (1) Select a three-dimensional through-hole copper foam with a thickness of 3mm and a pore size of 1500μm. Cut it into the required size (5cm×5cm), clean it with acetone and ethanol in an ultrasonic environment for 5min, dry it with nitrogen, and immerse it in a molar concentration Treat in 1mol / L hydrochloric acid aqueous solution for 60s to remove the oxide film on the surface and activate the surface of foamed copper tendons. After taking it out, wash it with 1mol / L sodium hydroxide aqueous solution and deionized water successively, and dry it with nitrogen;

[0037] (2) Immerse the activated copper foam in a closed 0.5mol / L ammonia solution for 48 hours, take it out, rinse it with clean water and dry it; put the ammonia solution in a closed container, heat it in a water bath, and the temperature is 5°C;

[0038] (3) Soak the activated and roughened copper foam in the stearic acid modification solution, soak it in a water bath at 95°C for 90 minutes, and then rinse it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com