Capillary enzyme array micro-reactor and its application

A micro-reactor and capillary technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of difficult miniaturization, complicated manufacturing steps, and limited applications.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

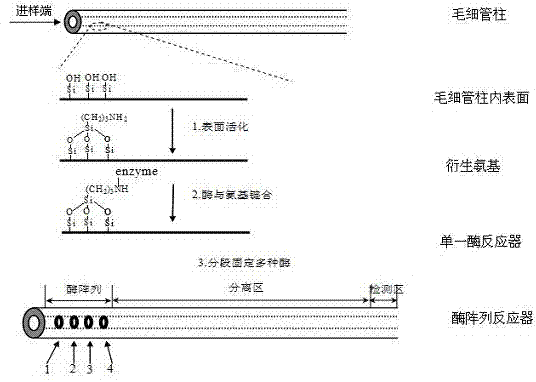

[0019] The specific preparation process of the capillary enzyme array microreactor: install a 50 cm long bare capillary on a capillary electrophoresis apparatus, pretreat with 0.1 mol / L hydrochloric acid for 30 minutes, and rinse with deionized water for 10 minutes. Inject the 3-aminopropyltrimethoxysilane ethanol solution (10%) with a length of 41.78mm at the injection end of the capillary with a pressure of 0.5psi×65s, and incubate the reaction for 120min. Reverse air for 10 minutes to remove unbonded silylating reagents, and immerse the sample inlet and sample outlet in deionized water for 5 minutes for cleaning. After the derivatization of the amino group is completed, inject a 9.64mm section of Trypsin solution (4u / ml) with an injection pressure of 0.5psi×15s. Air injection was used to push the enzyme solution to a position 32.14 mm away from the capillary injection port, and after 10 minutes of reaction, the air was reversed to remove unbonded Trypsin. Inject a 9.64mm m...

Embodiment 2

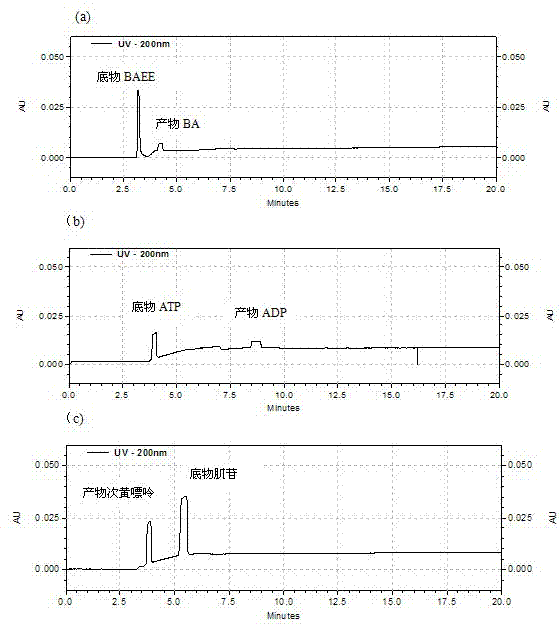

[0023] Using the capillary enzyme array microreactor of Example 1, three kinds of enzyme microreactors were constructed on the inner wall of the quartz capillary (50 μm in inner diameter, 40 cm in effective length), specifically, the inlet port has a PNP microreactor with a length of 9.64 mm; There is an EGFR enzyme microreactor with a length of 9.64mm at the position of 16.07mm from the end; there is a Trypsin microreactor with a length of 9.64mm at the position of 32.14mm from the inlet end. The array reactor was installed on a capillary electrophoresis apparatus. Based on the capillary electrophoresis procedure, H 2 O, 100mmol / L borax-boric acid buffer solution pH 8.0, followed by pressure washing, injecting 1mmol / LBAEE into the position of the array microreactor under pressure, the length does not exceed the total length of the enzyme array area, after incubation for 5min, apply 25kV forward voltage to separate. Use ultraviolet detection to collect the electrophoresis sp...

Embodiment 3

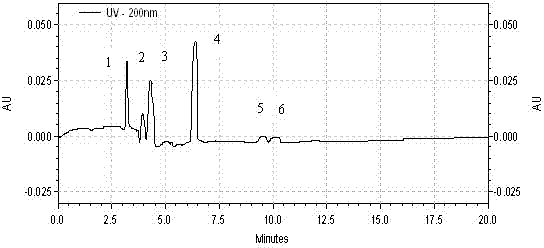

[0026] The capillary enzyme array microreactor prepared in Example 1 was used and installed on a capillary electrophoresis instrument. Based on the capillary electrophoresis procedure, H 2 O, 100mmol / L borax-boric acid buffer solution pH 9.5 was pressure-rinsed in sequence, and the mixed solution of 1mmol / LBAEE, ATP and inosine was injected into the reactor under pressure, and the length covered the enzyme array area. After incubation for 5 minutes, apply 25kV forward voltage to separate. Use ultraviolet detection to collect the electrophoresis spectrum at 200nm, and the ultraviolet absorption peaks of the substrate and product can be obtained. image 3(From left to right: 1. BAEE, 2. ATP, 3. Hypoxanthine, 4. Inosine, 5. BA, 6. ADP).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com