Method for processing Beryllium copper plate strip for secondary electronic emission

A secondary electron emission and processing method technology, which is applied in the field of material processing method protection, can solve the problems of high emission performance and low impurity content, and achieve the effect of good tissue uniformity, good adhesion, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

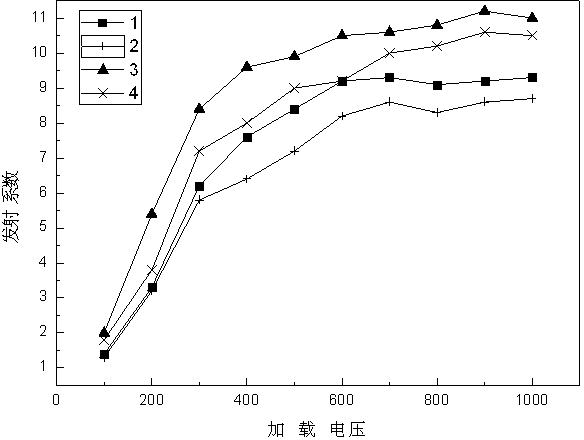

Image

Examples

Embodiment 1

[0017] Embodiment 1: Cu-2.7Be plate manufacture

[0018] (1) Mix a certain proportion of copper powder and beryllium-copper master alloy, and perform mechanical alloying in an omnidirectional planetary ball mill. The ball-to-material ratio is 10:1, the medium is alcohol, and the ball milling time is 10h.

[0019] The mixed powder is plasticized and extruded, and the binder is paraffin-edible oil-polyethylene glycol, wherein the volume fraction of paraffin wax is 50%, the volume fraction of edible oil is 20%, and the volume fraction of polyethylene glycol The volume fraction is 30%.

[0020] (2) After degreasing, it is sintered at 880°C under hydrogen and oxygen atmosphere, and the sintering time is 5h, and the ingot with a thickness of 3mm is made, and its composition is Be: 2.7%, Ni: 0.21wt.%, Fe : 0.058wt.%, Al: 0.013wt.%, Si: 0.028wt.%, Pb: 0.0020wt.%, Cd: 0.0020wt.%, Zn: 0.0020wt.%, the sum of other impurity elements is 0.43wt. %, the rest is Cu.

[0021] (3) Plastici...

Embodiment 2

[0023] Embodiment 2: Cu-2.7Be plate manufacture

[0024] The ingot billet is manufactured by the traditional vacuum melting process, the billet is heated to 760°C, kept for 0.5h, and then rolled. Pickling is carried out every three passes, and annealing is carried out in each pass in the middle. The annealing temperature is 750°C, and the reduction of each pass is controlled at about 30%, and finally rolled into a plate with a thickness of 0.15mm.

Embodiment 3

[0025] Embodiment 3: Cu-2.8Be plate manufacture

[0026] (1) Mix a certain proportion of copper powder and beryllium-copper master alloy, and carry out mechanical alloying in an omnidirectional planetary ball mill with a ball-to-material ratio of 15:1, the medium is alcohol, and the ball milling time is 15 hours.

[0027] (2) Plasticizing and extruding the mixed powder, the binder is paraffin-edible oil-polyethylene glycol, wherein the volume fraction of paraffin wax is 60%, the volume fraction of edible oil is 20%, polyethylene glycol The volume fraction of diol is 20%. After degreasing, it is sintered at 880°C under the atmosphere of hydrogen and oxygen, and the sintering time is 5h, and the ingot with a thickness of 3mm is made, and its composition is Be: 2.8%, Ni: 0.21wt.%, Fe: 0.058wt .%, Al: 0.013wt.%, Si: 0.028wt.%, Pb: 0.0020wt.%, Cd: 0.0020wt.%, Zn: 0.0020wt.%, the sum of other impurity elements is 0.43wt.%, the rest For Cu.

[0028] (3) Plasticized extrusion is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com