Preparation method of high-adhesion adhesive-free flexible copper-clad plates

A flexible copper clad laminate and glue type technology is applied in the field of preparation of high-adhesion non-adhesive flexible copper clad laminates, and can solve the problems that ultra-thin flexible copper clad laminates cannot be obtained, large-scale continuous production is difficult, and production costs are high. , to achieve the effects of good solubility and film formation, low production cost and low post-processing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

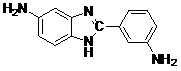

[0030] with N 2 In a 500 mL four-neck flask with a vent tube, a thermometer and a mechanical stirrer, under N 2 In the atmosphere, first add 5.6066 g (0.025 mol) of BIA and 7.4050 g (0.025 mol) of DMBB, and then add 250 g of NMP. After the diamine is completely dissolved, add 14.7112 g (0.05 mol) of BPDA. at 0 o C for 6 hours to generate the corresponding polyamic acid. Then add an appropriate amount of xylene to keep the reflux temperature at 150 o C. After continuing to heat for 24 hours, the xylene was completely distilled off, and the heating was stopped. After cooling down naturally, the reaction solution was poured into high-speed stirring methanol to obtain a precipitate. The obtained precipitate was thoroughly washed successively with methanol and anhydrous ether, filtered, dried naturally, and then dried in vacuum at 120°C for 24 hours to obtain polyimide powder. Using NMP as the mobile phase, the number average molecular weight (Mn) was 121325 and the weight aver...

Embodiment 2

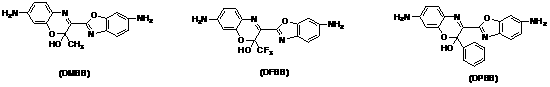

[0033] with N 2 In a 500 mL four-neck flask with a vent tube, a thermometer and a mechanical stirrer, under N 2 In the atmosphere, first add 6.7279 g (0.030 mol) of BIA and 7.0040 g (0.0020 mol) of DFBB, and then add 250 g of NMP. After the diamine is completely dissolved, add 15.5320 g (0.05 mol) of ODPA. at 15 o C for 8 hours to generate the corresponding polyamic acid. Add an appropriate amount of chlorobenzene to keep the reflux temperature at 180 o C. After continuing to heat for 18 hours, the chlorobenzene was completely distilled off, and the heating was stopped. After cooling down naturally, the reaction liquid was poured into high-speed stirring methanol to obtain a precipitate. The obtained precipitate was thoroughly washed successively with methanol and anhydrous ether, filtered, dried naturally, and then dried in vacuum at 120°C for 24 hours to obtain polyimide powder. Using NMP as the mobile phase, the number average molecular weight (Mn) was 78325 and the wei...

Embodiment 3

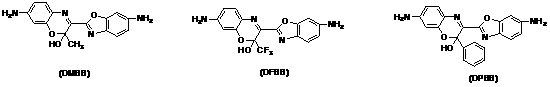

[0036] with N 2 In a 500 mL four-neck flask with a vent tube, a thermometer and a mechanical stirrer, under N 2 In the atmosphere, first add 7.8493 g (0.0350 mol) of BIA and 5.3741 g (0.0150 mol) of DPBB, and then add 250 g of NMP. After the diamine is completely dissolved, add 16.1325 g (0.0500 mol) of BTDA. at 40 o C for 10 hours to generate the corresponding polyamic acid. Then add an appropriate amount of xylene to keep the reflux temperature at 160 o C. After continuing to heat for 48 hours, completely distill out the xylene, stop heating, wait for it to cool naturally, pour the reaction solution into high-speed stirring methanol, and obtain a precipitate. The obtained precipitate was thoroughly washed successively with methanol and anhydrous ether, filtered, dried naturally, and then dried in vacuum at 120°C for 24 hours to obtain polyimide powder. Using NMP as the mobile phase, the number average molecular weight (Mn) was 58354 and the weight average molecular weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com