Fragrant artificial leather and preparation method thereof

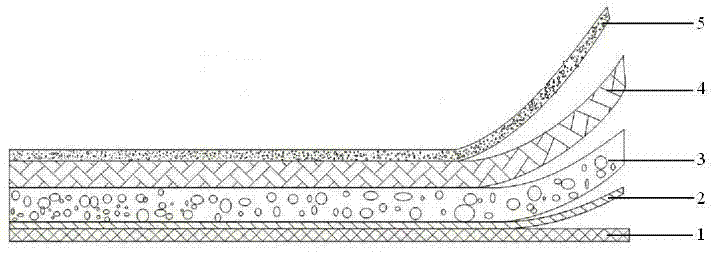

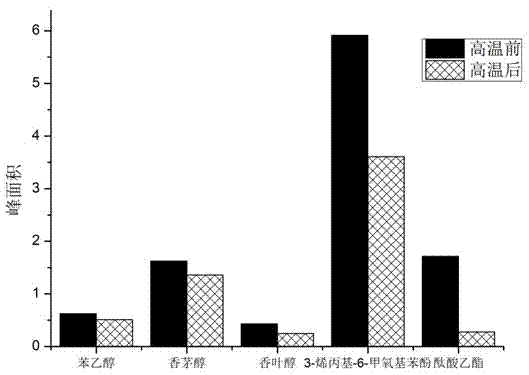

A fragrant artificial leather and fragrance technology, applied in the field of leather, can solve the problems of poor heat resistance, short fragrance lasting time, etc., and achieve the effects of beautiful appearance, easy industrial production and mature technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 75kg of plasticizer diisodecyl phthalate, 20kg of 800 mesh heavy calcium powder, 3kg of liquid barium zinc heat stabilizer, and then add 100kg of PVC paste resin and 5kg of color paste while stirring in a 300L mixing tank. After 20 minutes, use a vacuum stirring and defoaming machine to defoam for 30 minutes at -0.1MPa to obtain the top layer material.

[0036] Add 160kg of plasticizer diisodecyl phthalate, 140kg of 800 mesh heavy calcium powder, 2kg of liquid barium-zinc heat stabilizer, and 6kg of liquid potassium-zinc heat stabilizer in a 300L mixing tank, and then add PVC paste while stirring 200kg of resin, 10kg of color paste, 6kg of AC foaming agent, stirred for 30 minutes, and defoamed at -0.1MPa for 30 minutes with a vacuum stirring and defoaming machine to obtain a foamed layer.

[0037] 50kg of water-based polyurethane adhesive is used directly.

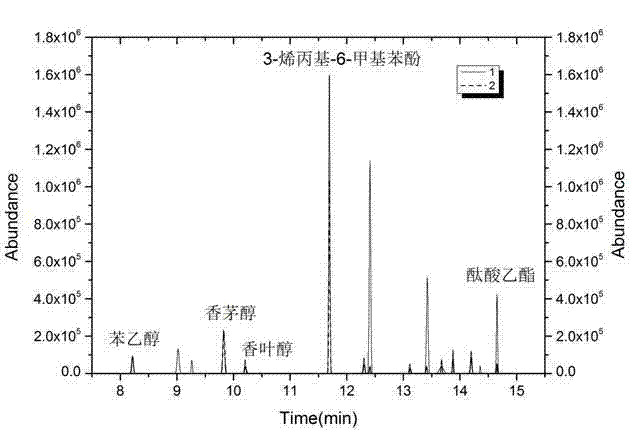

[0038] Add 30kg of water-based polyurethane finishing agent into a 50L mixing tank, then add 0.9kg of rose-f...

Embodiment 2

[0044] Add 100kg of water-based polyurethane surface layer resin and 5kg of color paste into a 300L mixing tank, stir for 20 minutes, and use a vacuum stirring defoamer to defoam at -0.1MPa for 30 minutes to obtain the surface layer material.

[0045] Add 200kg of water-based polyurethane foam layer resin and 10kg of color paste into a 300L mixing tank, stir for 30 minutes, and use a vacuum stirring defoamer to defoam at -0.1MPa for 30 minutes to obtain a foam layer.

[0046] 50kg of water-based polyurethane adhesive is used directly.

[0047] Add 30kg of water-based polyurethane finishing agent into a 50L mixing tank, and then add 0.9kg of mint fragrance finishing agent while stirring, 0.9kg of compatibilizer polyethylene glycol, and 1.2kg of crosslinking agent polycarbodiimide, stir for 15 minutes, add Ionized water adjusts the viscosity of the finishing agent to 300MPa.s to obtain an aromatic water-based PU finishing agent.

[0048] The production line speed of the coating...

Embodiment 3

[0051] Add 75kg of plasticizer diisodecyl phthalate, 20kg of 800 mesh heavy calcium powder, 3kg of liquid barium zinc heat stabilizer, and then add 100kg of PVC paste resin and 5kg of color paste while stirring in a 300L mixing tank. After 20 minutes, use a vacuum stirring and defoaming machine to defoam for 30 minutes at -0.1MPa to obtain the top layer material.

[0052] Add 160kg of plasticizer diisodecyl phthalate, 140kg of 800 mesh heavy calcium powder, 2kg of liquid barium-zinc heat stabilizer, and 6kg of liquid potassium-zinc heat stabilizer in a 300L mixing tank, and then add PVC paste while stirring 200kg of resin, 10kg of color paste, 6kg of AC foaming agent, stirred for 30 minutes, and defoamed at -0.1MPa for 30 minutes with a vacuum stirring and defoaming machine to obtain a foamed layer.

[0053] 50kg of water-based polyurethane adhesive is used directly.

[0054] Add 30kg of water-based polyurethane finishing agent into a 50L mixing tank, then add 1.5kg of sweet-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com