Zolpidem molecularly imprinted solid-phase extraction columella

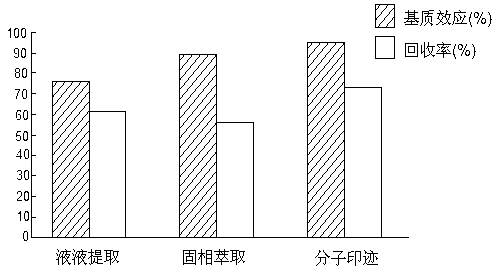

A solid-phase extraction cartridge, zolpidem molecule technology, applied in the direction of material separation, analysis of materials, separation methods, etc., can solve the problems of weak specificity, large amount of organic solvent, and more interference of impurities, and achieves auxiliary identification and Detection, high selectivity, high specificity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

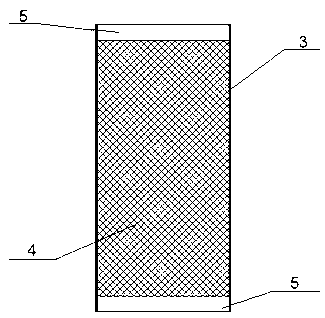

[0036] 1mmol zolpidem was dissolved in 10mL chloroform, 4mmol methacrylic acid was added, and placed in a shaker for 1h, so that the template molecules and functional monomers could fully interact.

[0037] Then add 40mmol crosslinking agent ethylene glycol dimethacrylate, 100mg initiator 1,1-dimethyl-1-hydroxyacetophenone, after fully dissolving, transfer the mixed solution into a 50mL ampoule bottle, discharge oxygen, Vacuum tight.

[0038] Place the sealed ampoule in a water bath, irradiate with a 1000W high-pressure mercury lamp for 4 hours, and react to produce a hard solid polymer. Grind and sieve the obtained polymer, collect the polymer with a particle size of 75-125 μm, and pump it in Soxhlet Wash the container with methanol-acetic acid (volume ratio 8:2) until no zolpidem is detected by UV detection, and then wash away the acetic acid with methanol. The polymer was dried under vacuum at 60 °C for 24 h.

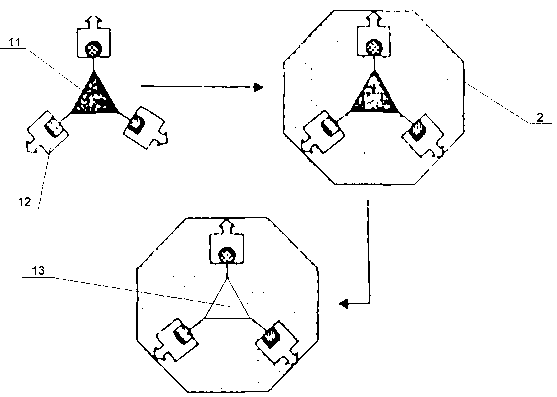

[0039] The polymer with a particle size of 75-125 μm was used a...

Embodiment 2

[0046] 1mmol of zolpidem was dissolved in 10mL of chloroform, 8mmol of methacrylic acid was added, and placed in a shaker for 1.5h to make the template molecules fully interact with the functional monomers.

[0047] Then add 100mmol crosslinking agent ethylene glycol dimethacrylate and 100mg initiator diphenyl ethyl ketone, after fully dissolving, transfer the mixed solution into a 50mL ampoule bottle, discharge oxygen, and vacuum seal.

[0048] Place the sealed ampoule in a water bath, irradiate with a 1000W high-pressure mercury lamp for 5 hours, and react to produce a hard solid polymer. Grind and sieve the obtained polymer, collect the polymer with a particle size of 75-125 μm, and pump it in Soxhlet Wash the container with methanol-acetic acid (volume ratio 8:2) until no zolpidem is detected by UV detection, and then wash away the acetic acid with methanol. The polymer was dried under vacuum at 60 °C for 24 h.

[0049] The polymer with a particle size of 75-125 μm was us...

Embodiment 3

[0052] 1mmol of zolpidem was dissolved in 10mL of chloroform, 2mmol of methacrylic acid was added, and placed in a shaker for 1.5h to make the template molecules fully interact with the functional monomers.

[0053] Then add 30mmol crosslinking agent ethylene glycol dimethacrylate, 100mg initiator 2-hydroxyl-2-methyl-1-phenylacetone, after fully dissolving, transfer the mixed solution into a 50mL ampoule bottle, discharge oxygen, Vacuum tight.

[0054] The sealed ampoule was placed in a water bath and irradiated by a 1000W high-pressure mercury lamp for 3.5 hours to produce a hard solid polymer. The obtained polymer was ground and sieved, and the polymer with a particle size of 75-125 μm was collected. Wash with methanol-acetic acid (volume ratio 8:2) in the gas tank until no zolpidem is detected by ultraviolet detection, and then wash away the acetic acid with methanol. The polymer was dried under vacuum at 60 °C for 24 h.

[0055] The polymer with a particle size of 75-125...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com