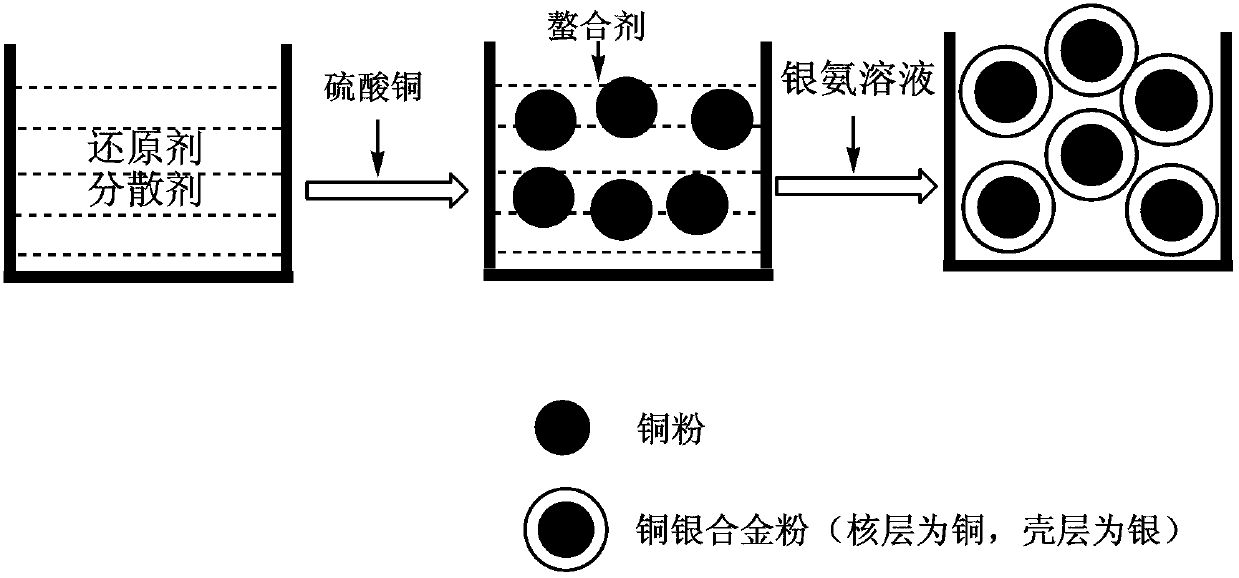

Method for preparing compact silver-coated copper powder by using one pot method

A silver-coated copper powder, dense technology, applied in the field of one-pot preparation of dense silver-coated copper powder, can solve the problems of fast reaction speed, reduced silver use efficiency, high cost, etc., to increase the resistance, improve the coating effect, save The effect of the precious metal silver

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] First prepare the hydroxymethylamine condensate dispersant: take 9 grams of anhydrous ethylenediamine and dissolve it in 9 grams of deionized water, then take 50 grams of formaldehyde solution with a mass fraction of 37%, and add the formaldehyde solution to ethyl alcohol under stirring. In diamine, react for 2 hours and use it as a dispersant for later use.

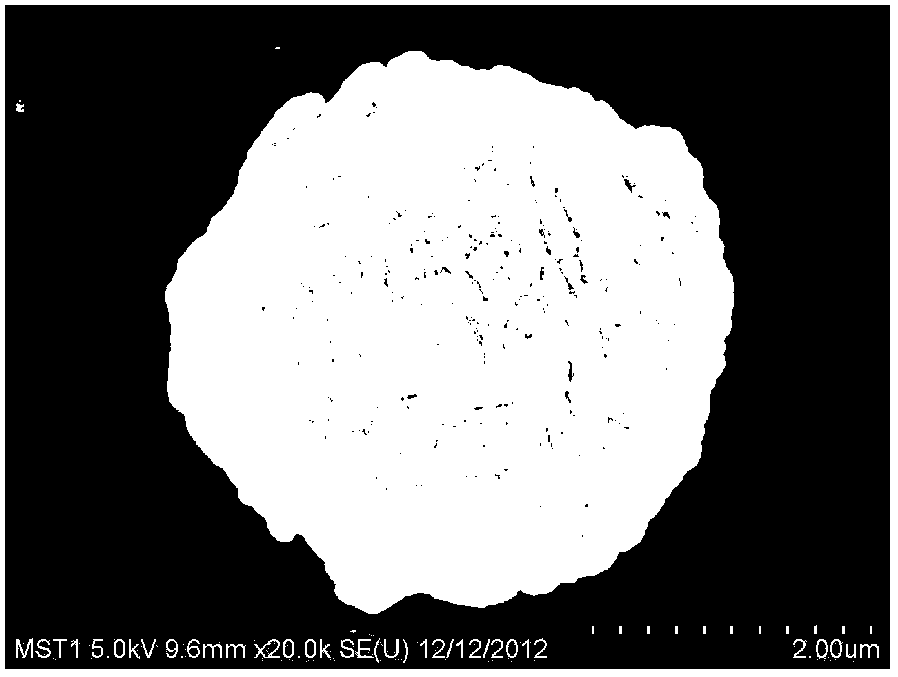

[0026] Get 18 grams of silver nitrate and 13 grams of 28% ammonia solution and dissolve it in 180 milliliters of deionized water to make silver ammonia solution; get 43 grams of copper sulfate and 33 grams of 28 percent ammonia solution and dissolve it in 500 milliliters of deionized water to make copper ammonia Aqueous solution: 48 grams of ascorbic acid and 12 grams of hydroxymethylamine condensate dispersant solution were dissolved in 500 milliliters of deionized water to prepare a mixed aqueous solution of reducing agent and dispersant. At a stirring speed of 160 rpm, add the cuproammonia aqueous solution to t...

Embodiment 2

[0028] Get 30 grams of silver nitrate and 22 grams of 28% ammonia solution and dissolve it in 300 milliliters of deionized water to make silver ammonia solution; get 43 grams of copper sulfate and 33 grams of 28 percent ammonia solution and dissolve it in 500 milliliters of deionized water to make copper ammonia Aqueous solution: 48 grams of ascorbic acid and 14 grams of hydroxymethylamine condensate dispersant solution were dissolved in 500 milliliters of deionized water to prepare a mixed aqueous solution of reducing agent and dispersant. At a stirring speed of 160 rpm, add the cuproammonia aqueous solution to the mixed water solution composed of a reducing agent and a dispersant, control the temperature at 70° C., and react for 2 hours under stirring to obtain a suspension containing copper powder; Add 35 grams of N,N'-bis(2-hydroxybenzyl)ethylenediamine-N,N'-diacetic acid to the copper powder suspension, then add the silver ammonia solution of silver nitrate to the suspensi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com