Preparation method of spherical water-absorbent resin and cold warm compress product thereof

A water-absorbing resin, spherical technology, applied in the field of polymer resin preparation, can solve problems such as unfavorable industrial production, increase in resin particle size factors, increase in synthesis steps, etc., and achieve simple equipment, excellent heat and cold storage performance, and shortened reaction time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The preparation method of the spherical water-absorbent resin in this embodiment comprises the following steps:

[0031] Step 1, the preparation of aqueous phase solution:

[0032] Add 13.2g of NaOH to 29.2g of water, stir to make it completely dissolve and cool down. After the NaOH solution drops to room temperature, add this solution to 22.2g of methacrylic acid monomer, and stir and cool it. When the temperature is below 25°C, adjust the pH to 6.5-6.7;

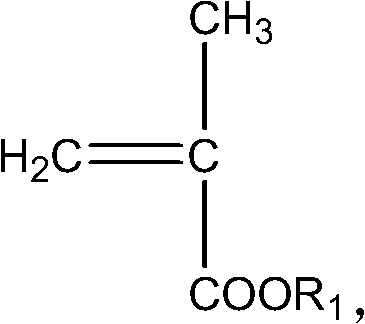

[0033] Then add 0.1~0.2g of cross-linking agent N,N-methylenebisacrylamide, stir rapidly until it is completely dissolved, then add 0.08~0.1g of potassium persulfate, 0.004~0.006g of Sodium bisulfate and 0.01g of triethanolamine, keep the temperature of the system at about 10°C to obtain an aqueous phase solution; the density of the aqueous phase solution is 0.9g / cm 3 .

[0034] Step 2, preparation of oil phase solution:

[0035] Take by weighing 250g glyceryl monostearate, 150kg dimethyl carbonate, 100kg hexanap...

Embodiment 2

[0041] The preparation method of the spherical water-absorbent resin in this embodiment comprises the following steps:

[0042] Step 1, the preparation of aqueous phase solution;

[0043] Add 19.3g of KOH to 23.2g of water, stir to make it completely dissolve and cool down. After the KOH solution drops to room temperature, add this solution to 29.2g of butyl methacrylate monomer, and stir and cool. After cooling to below 25°C, adjust the pH within the range of 6.5 to 6.7;

[0044] Then add 0.1~0.2g of cross-linking agent N,N-methylenebisacrylamide, stir rapidly until it is completely dissolved, then add 0.08~0.1g of potassium persulfate, 0.004~0.006g of The hydrogen peroxide (mass fraction is 30%) of sodium bisulfate and 0.01g, keeps system temperature at about 10 ℃; The density of described aqueous phase solution is 1.0g / cm 3 ;

[0045] Step 2, the preparation of oil phase solution;

[0046] Take by weighing 300g ethyl cellulose, 100kg dimethyl carbonate, 150kg carbon tet...

Embodiment 3

[0052] The preparation method of the spherical water-absorbent resin in this embodiment comprises the following steps:

[0053] Step 1, the preparation of aqueous phase solution;

[0054] Add 21.5g of NaOH to 26.2g of water, stir to make it completely dissolve and cool down. After the NaOH solution drops to room temperature, add this solution to 30.2g of methacrylic acid monomer, and stir and cool it. When the temperature is below 25°C, adjust the pH within the range of 6.5 to 6.7;

[0055] Then add 0.05~0.1g of cross-linking agent N,N-methylenebisacrylamide, stir rapidly until it is completely dissolved, then add 0.08~0.1g of potassium persulfate, 0.004~0.006g of Sodium bisulfate and 0.01g of diethanolamine, keep the system temperature at about 10°C; the density of the aqueous phase solution is 1.0g / cm 3 ;

[0056] Step 2, the preparation of oil phase solution;

[0057] Take by weighing 500g sorbitan oleate, 300kg dimethyl carbonate and premix evenly to obtain an oil phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com