Preparation method of cellulose-g-resin acid grafted copolymer

A technology of graft copolymer and resin acid, which is applied in the field of preparation of cellulose-g-resin acid graft copolymer, can solve the problems of easy destruction of cellulose skeleton, application limitation, uncontrollable molecular weight and molecular weight distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

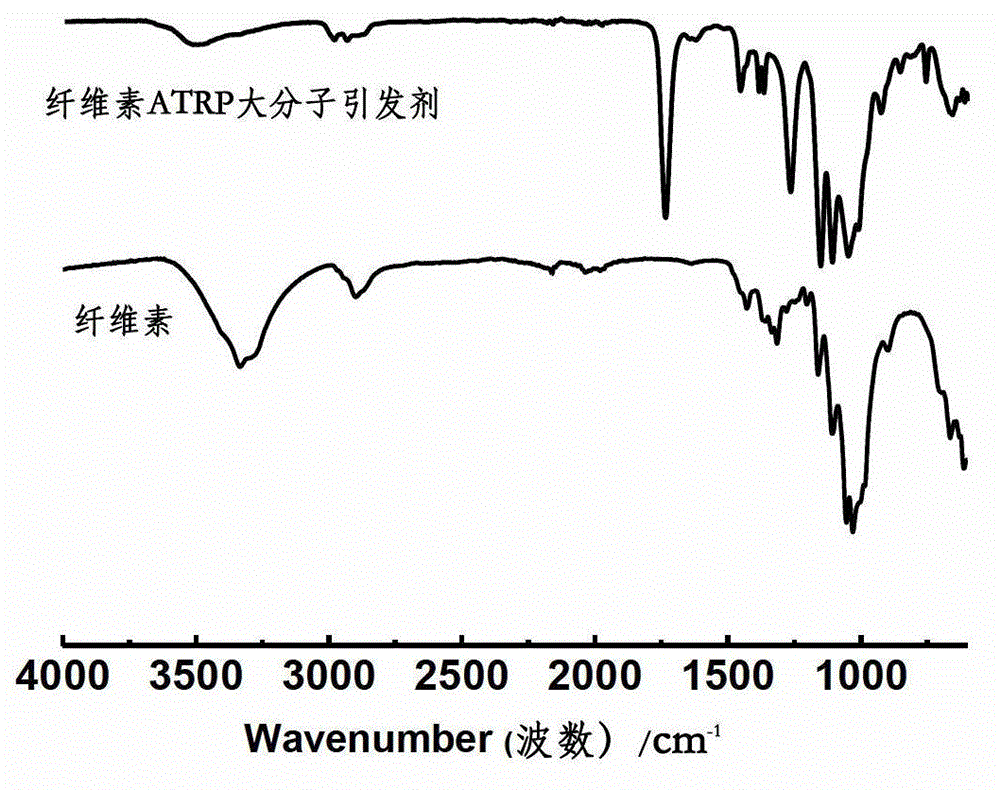

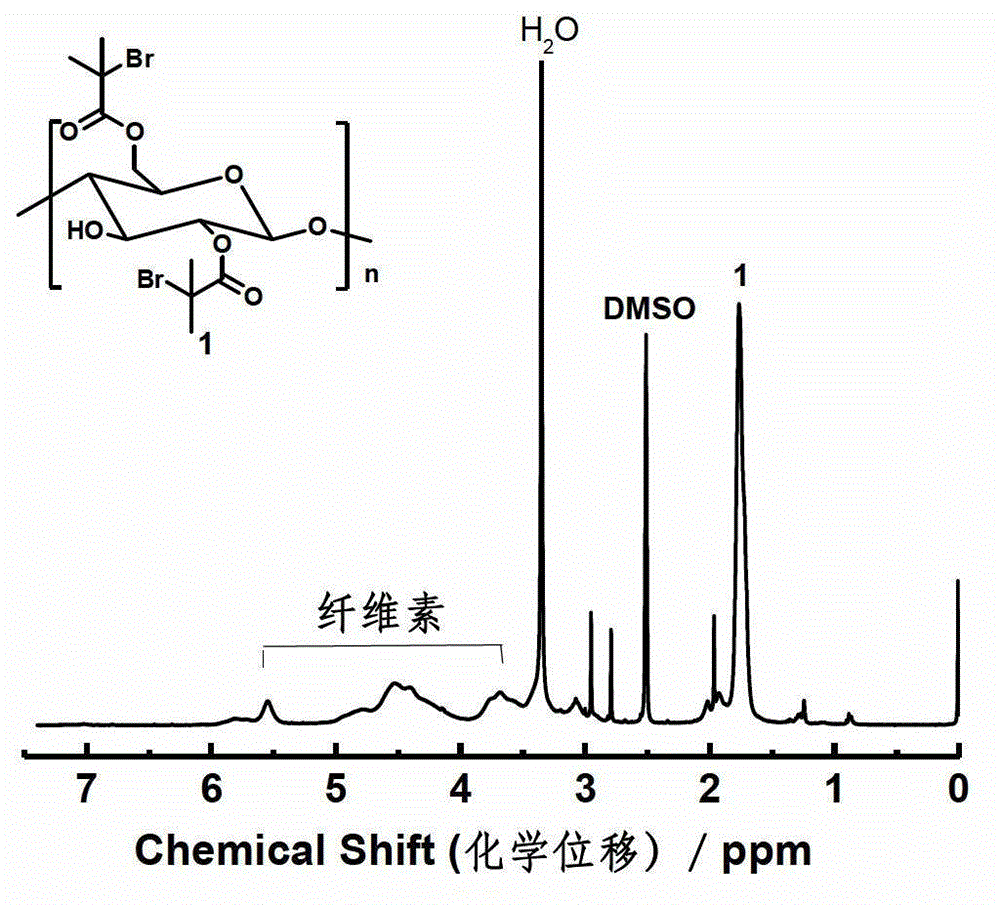

[0032] A kind of preparation method of cellulose-g-resin acid graft copolymer, the steps are:

[0033] (1) Reaction of cellulose with 2-bromoisobutyryl bromide in a homogeneous solution system to synthesize a cellulose atom transfer radical polymerization (ATRP) macroinitiator; (2) Resin acid-based monomer, cellulose ATRP Macromolecular initiators, catalysts and ligands are added to the reaction flask with a certain molar ratio and solvent, fully stirred and dissolved, and the oxygen in the mixed solution is removed through three (freezing-vacuum-nitrogen) cycle processes. o After reacting in C for 1-24 h, the polymer was precipitated in methanol, then filtered and dried to obtain the cellulose-g-resin acid graft copolymer. Cellulose-g-resin acid graft copolymers with different molecular weights and molecular weight distributions can be obtained by this method.

[0034] Cellulose is microcrystalline cellulose with low crystallinity;

[0035] The homogeneous solution syste...

Embodiment 1

[0046] (1) Cellulose pretreatment

[0047] First, put 2.0g of microcrystalline cellulose in a vacuum drying oven, and dry it under vacuum at 110°C for 24 hours to remove residual small molecule impurities in the microcrystalline cellulose, and then disperse the pre-dried microcrystalline cellulose into 100ml of distilled water Water activation treatment, after stirring for 30 minutes, filter to remove water, and repeat the water activation treatment three times; the dehydrated microcrystalline cellulose is then dispersed in 100ml methanol for methanol activation treatment, after stirring for 30 minutes, filter and remove water, and the methanol activation treatment is repeated three times; Finally, the microcrystalline cellulose was dried in a vacuum oven at 50° C. for 3 hours to complete the cellulose pretreatment.

[0048] (2) Preparation of cellulose homogeneous solution

[0049] Dissolve 2.0 g of the above-mentioned pretreated cellulose in 120 ml of dimethylacetamide, h...

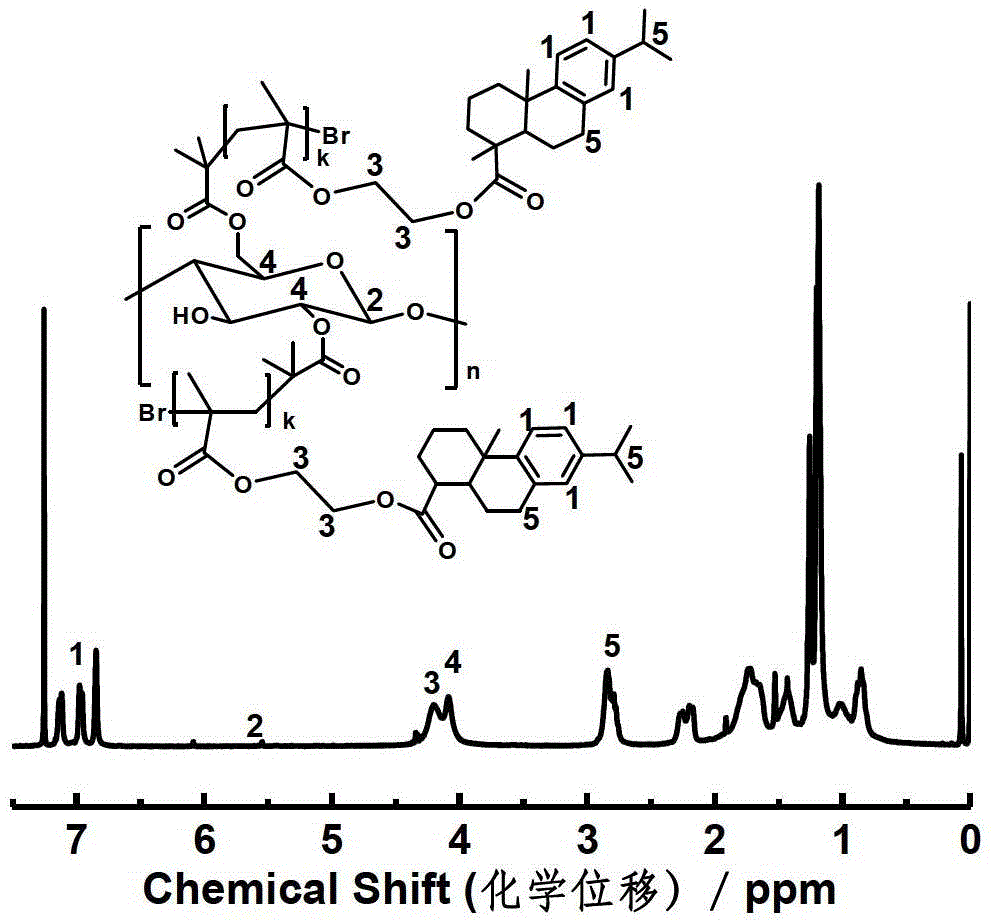

Embodiment 2

[0057] [Monomer] / [Initiator] / [Catalyst] / [Ligand]=100:1:2:1 (molar ratio)

[0058] The cellulose macroinitiator (prepared in Example 1) 2.65mg (0.0125mmol Br), the ligand N,N,N,N,N-pentamethyldiethylenetriamine (PMDETA) 2.6μL (0.0125 mmol), monomer (DAME) 0.515 g (1.25 mmol) was dissolved in 2 mL tetrahydrofuran (THF), and the oxygen in the mixed solution was removed through three cycles (freezing-vacuumizing-nitrogen filling). At the same time, 4.25mg Cu(I)Br (2.5mmol) was weighed into the polymerization bottle, filled with nitrogen and deoxygenated, then the mixed solution was transferred to the polymerization bottle, and put into 80 o C in an oil bath for 12 hours. After the reaction, the reactant was passed through a neutral aluminum oxide column to remove the copper catalyst, dropped into a large amount of methanol for precipitation, filtered to collect the precipitate, and finally dried in a vacuum oven at room temperature for 24 hours. The monomer conversion rate is 35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com