Flue gas denitration method based on advanced oxidization technology

An advanced oxidation technology and flue gas technology, applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of low photocatalyst activity, high energy consumption, easy deactivation, etc., and achieve low cost and low energy consumption. , The effect of low denitration cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

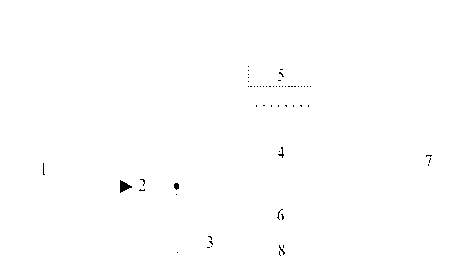

[0035] Dust-free layout scheme for simultaneous flue gas desulfurization and denitrification

[0036] 1) Prepare a double oxidant solution, which includes 1wt% H 2 o 2 , 0.1mol / LNa 2 S 2 o 8 , and the active ingredient 0.05mol / LCl - , C(OH - ):C(HPO 4 - )=1:1;

[0037] 2) Spray the prepared double oxidant solution directly into the flue and mix it with the flue gas after dedusting. The reaction temperature of the flue is 90-110°C;

[0038] 3) The oxidized flue gas enters the absorption tower 4 and utilizes CaCO 3 The slurry simultaneously absorbs SO 2 and NO x , generate by-products such as calcium sulfite, calcium nitrate and calcium nitrite, the absorption liquid is recycled, and the by-products are recycled through the by-product recovery system 8. The flue gas enters the chimney 7 after passing through the demister 5 . The process can achieve a denitrification efficiency greater than 85%.

Embodiment 2

[0040] Dust-free layout scheme for simultaneous flue gas desulfurization and denitrification

[0041] 1) Prepare a double oxidant solution, which includes 1wt% H 2 o 2 , 5mol / LNa 2 S 2 o 8 , and the active ingredient 0.03mol / LCl - , C(OH - ):C(HPO4 - )=1:1;

[0042] 2) Spray the prepared double oxidant solution directly into the flue and mix it with the flue gas after dedusting. The reaction temperature of the flue is 90-110°C;

[0043] 3) The oxidized flue gas enters the absorption tower 4, and the urea solution is used to absorb SO at the same time 2 and NO x , generating ammonium sulfite, ammonium sulfate, N 2 , CO 2 and other by-products, the absorption liquid is recycled, and the by-products are recycled through the by-product recovery system 8. The flue gas enters the chimney 7 after passing through the demister 5 . The process can achieve a denitrification efficiency greater than 85%.

[0044] The scheme of embodiment 1 and embodiment 2 is as figure 1 sho...

Embodiment 3

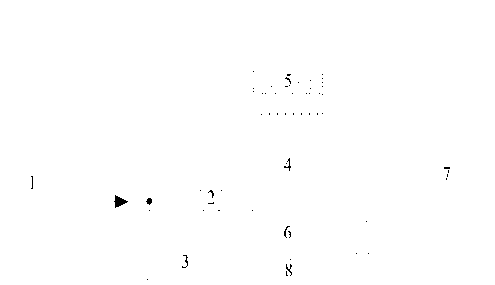

[0046] Dust-containing layout scheme for simultaneous desulfurization and denitrification of flue gas

[0047] 1) Prepare a double oxidant solution, which includes 50wt% H 2 o 2 , 0.1mol / LNa 2 S 2 o 8 , and the active ingredient 0.01mol / LCl - , C(OH - ):C(HPO 4 - )=1:1;

[0048] 2) Spray the prepared double oxidant solution directly into the flue, before the high-efficiency dust collector, and the reaction temperature of the flue is 110-150°C;

[0049] 3) The oxidized flue gas enters the absorption tower 4 through the high-efficiency dust collector, and the calcium hydroxide slurry is used to absorb SO at the same time 2 and NO x , generate by-products such as calcium sulfite, calcium nitrate and calcium nitrite, the absorption liquid is recycled, and the by-products are recycled through the by-product recovery system 8. The flue gas enters the chimney 7 after passing through the demister 5 . The process can achieve a denitrification efficiency greater than 85%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com