Solid phase microextraction coating of hydroxyl cucurbituril as well as preparation method and application thereof

A hydroxyl cucurbit ring and coating technology is applied in the field of analytical chemistry to achieve the effects of diverse extraction structures, good stability and flexible extraction methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

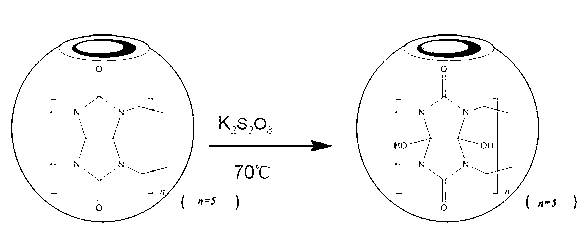

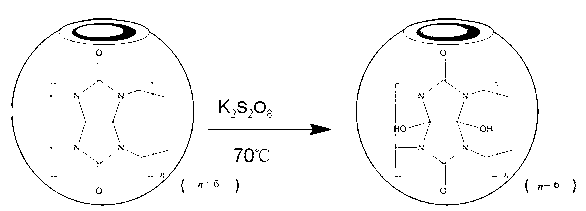

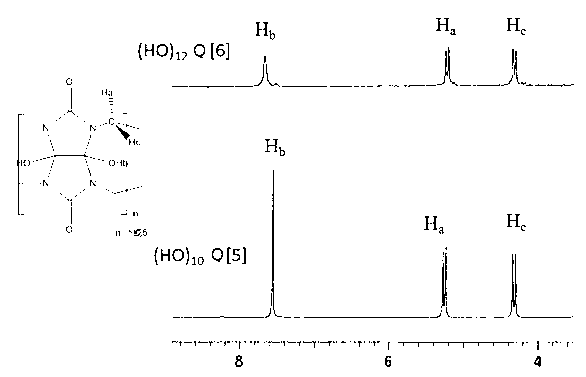

[0031] Example 1 Preparation of High Purity Fully Substituted Hydroxycutrul Rings

[0032] The present invention mainly adopts two kinds of hydroxyl cucurbit rings (decahydroxyl five-membered cucurbit rings, twelve-hydroxyl six-member cucurbit rings) to be chemically bonded on the sol-gel network to prepare the coating. The common melon ring five-membered melon ring or six-membered melon ring is used as the starting material, which is oxidized to a fully substituted hydroxy melon ring by potassium persulfate, and is separated and purified by Dowex strong acid cation exchange resin. Dissolve the synthesized crude hydroxycutrul ring in 100 mL of 20% acetic acid solution containing 0.03 mol / L hydrochloric acid, load the sample on a Dowex column pre-rinsed with 20% acetic acid solution, wash with gradient, and collect a bottle of elution for every 250 mL liquid. The first 20 bottles were rinsed with 20% acetic acid solution containing 0.03mol / L hydrochloric acid, then the 20 b...

Embodiment 2

[0033] Example 2 Preparation of Fully Substituted Hydroxycucurene Sol-Gel Solid-Phase Microextraction Coatings

[0034] Take a 10 mL polyvinyl chloride centrifuge tube and add hydroxyl cucurbitan (HO) 2n Q [n] (n=5,6) 20mg, dichloromethane (CH 2 Cl 2 ) 700 μL, hydroxyl-terminated polydimethylsiloxane (OH-PDMS) 150 μL, hydrogen-containing silicone oil (PMHS) 30 μL, tetraethyl silicate (TEOS) 250 μL, γ-glycidyl etheroxypropyl trimethoxy Then add 600 μL of 95% trifluoroacetic acid (TFA), shake for 3 min, and centrifuge at 12000 r / min for 5 min. Take the supernatant as a sol-gel coating.

Embodiment 3

[0035] Example 3 Preparation of Fibers for Solid Phase Microextraction

[0036] Pretreatment of quartz fiber: Take a quartz fiber with a length of 10 cm and a diameter of 20 μm, of which 1 cm is used as an adhesive sol-gel coating. After soaking in acetone for 3 hours and drying, place in 1 mol / L NaOH solution for 1 hour to carry out hydroxylation treatment on the quartz surface, and then put it in 0.1 mol / L HCl solution for 30 minutes to neutralize the residual NaOH on the surface, distilled water Wash and dry under nitrogen protection.

[0037] After the treated quartz fiber was inserted into the sol-gel coating solution for 30 min, it was pulled vertically, and the coating thickness was controlled by dipping times. Put the coated quartz fiber at room temperature for 24 h.

[0038] Remove the jacket of the 5 μL micro-sampler needle, cut off 2 cm from the front end, and assemble it with the inner core of the 1 μL micro-sampler. And glue the finished quartz fiber to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com