Feed adhesion agent

An adhesive and feeding technology, applied in the direction of adhesive type, protein adhesive, cellulose adhesive, etc., can solve the problems of complicated operation, polluted water body, slow digestion and absorption, etc. Convenient, easy to produce effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation of embodiment 1 feed binder

[0030] Materials: kelp, kelp, kelp, spirulina, spirulina, Schizochytrium, Nannochloropsis or chlorella and their processing by-products (purchased from the market), povidone-K30 (purchased from the market), carboxymethyl fiber Su Na (purchased from the market), Qiangqiang powder (produced by Shanghai Ximenong Biotechnology Co., Ltd.), pellet feed (purchased from the market).

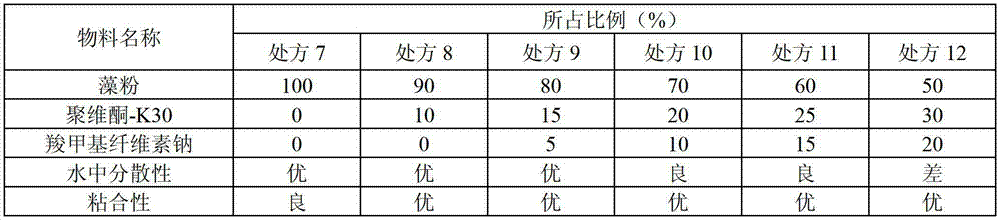

[0031] Prescription: See Table 1, Table 2

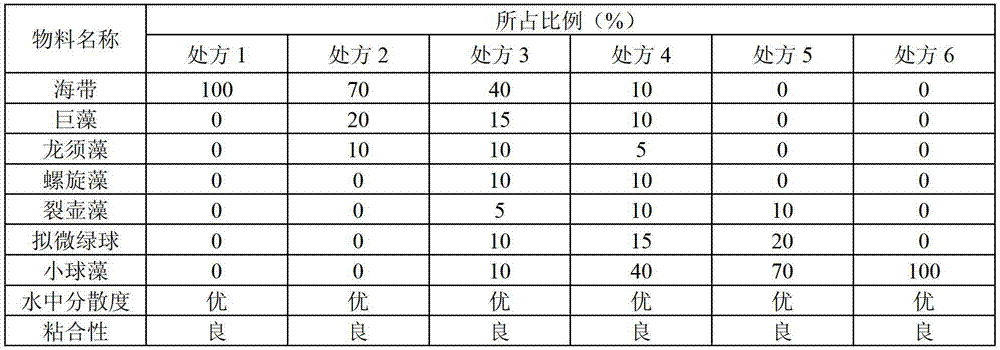

[0032] Table 1 Screening scheme and results of feed algae powder prescription

[0033]

[0034] Preparation method: take algae for feeding, spread out and ventilate and dry at 60°C until the water content is less than 1% (measured according to the "weight loss on drying method" in the Chinese Veterinary Medicine Code), mix according to the ratio specified in the prescription, and then pulverize with a high-efficiency pulverizer When the particle size is greater than 80 meshes (measured according to the "...

Embodiment 2

[0044] Application of embodiment 2 feed adhesive on pig breeding

[0045] Materials: Adhesive for feed (prepared according to prescription 8); Jianzhu Powder (produced by Chengdu Qiankun Animal Pharmaceutical Co., Ltd.); red yeast rice flour (purchased from the market); pelleted feed (purchased from the market); experimental pigs (from a pig in Chengdu 50 healthy pigs with a weight of about 50kg).

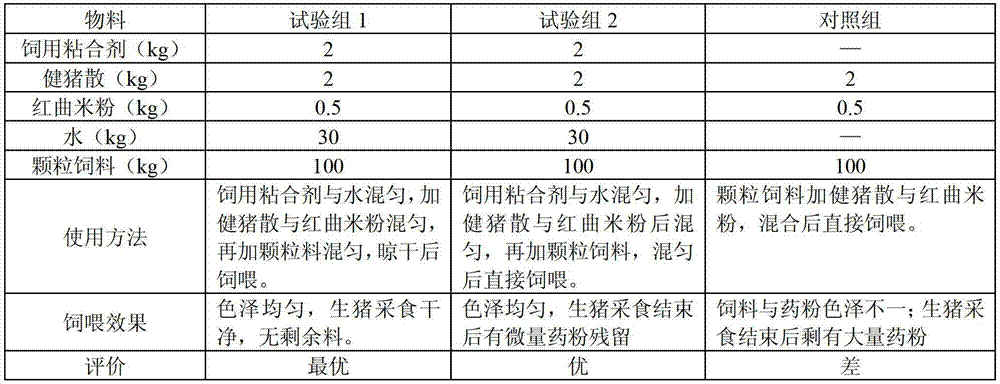

[0046] Method: See Table 3.

[0047] Table 3 The experimental methods and results of the application of feed adhesives in pig breeding

[0048]

[0049] It can be seen from Table 3 that the application of feed binders can greatly improve the distribution uniformity of powder additives in pellet feed, ensure that the additives are eaten by pigs together with the feed, and overcome the difficulty of mixing powder additives with pellets. Disadvantages of using materials together. Considering the operability and the utilization rate of additives, it is better to use feed binders,...

Embodiment 3

[0050] Application of embodiment 3 feed binder on broiler breeding

[0051] Materials: Feed binder (prepared according to prescription 8); Jianji Powder (produced by Chengdu Qiankun Animal Pharmaceutical Co., Ltd.); red yeast rice flour (purchased from the market); pelleted feed (purchased from the market); chicken for experiment (a chicken from Leshan 1000 healthy broilers with a field weight of about 1.5kg).

[0052] Method: See Table 4.

[0053] Table 4 The experimental methods and results of the application of feed binders in broiler farming

[0054]

[0055]It can be seen from Table 4 that the application of feed binders can greatly improve the distribution uniformity of powder additives in pellet feed, ensure that the additives are eaten by the chickens together with the feed, and overcome the difficulty of mixing powder additives. Disadvantages of using pellets together. Considering the operability and the utilization rate of additives, it is better to use feed bi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com