Light emitting diode (LED) epitaxial wafer with N type insertion layer with trapezoidal structure and growth method thereof

A technology of LED epitaxial wafer and trapezoidal structure, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of enhanced vertical confinement and reduced electron quantity, and achieve the effects of avoiding confinement, improving crystal quality and promoting lateral movement of electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

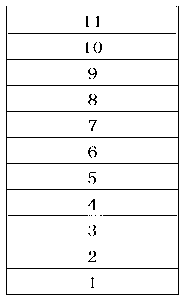

[0024] Such as figure 1 The shown LED epitaxial wafer structure includes, from bottom to top, substrate 1, low-temperature GaN buffer layer 2, GaN undoped layer 3, first N-type GaN layer 4, N-type AlGaN insertion layer 5, second N-type GaN layer 6 , multiple quantum well layer 7 , low-temperature P-type GaN layer 8 , P-type AlGaN layer 9 , high-temperature P-type GaN layer 10 , and P-type contact layer 11 .

[0025] In this example, high-purity hydrogen (H2) or nitrogen (N2) is used as carrier gas, trimethylgallium (TMGa), triethylgallium (TEGa), trimethylaluminum (TMAl), trimethylindium (TMIn ) and ammonia (NH3) as sources of Ga, Al, In, and N, respectively, and silane (SiH4) and magnesocene (CP2Mg) as N and P-type dopants, respectively.

[0026] The method for growing a GaN-based LED epitaxial structure with an N-type insertion layer of a trapezoidal structure in this embodiment includes the following specific steps:

[0027] Step 1: Clean the substrate 1 at a high tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com