Method for producing metal complex quantum crystals

A metal complex and quantum crystal technology, applied in the direction of silver compounds, silver compounds, silver organic compounds, etc., can solve the problems of sample deterioration, poor repeatability of measurement results, and difficulty in real-time detection, and achieve good repeatability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

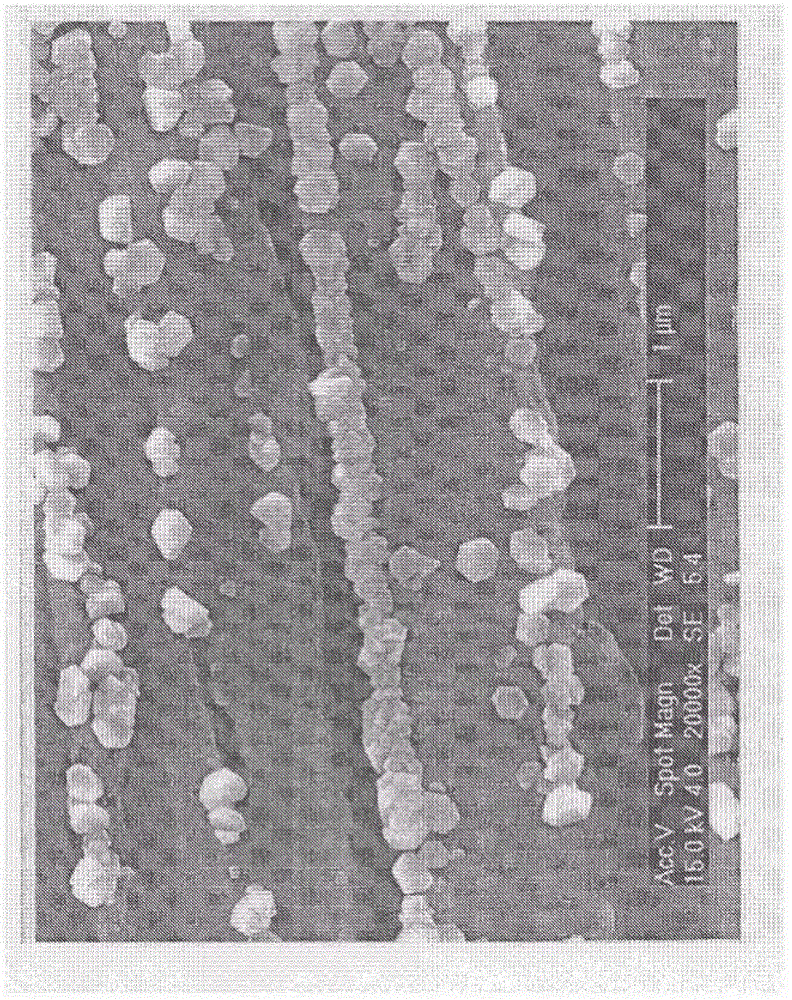

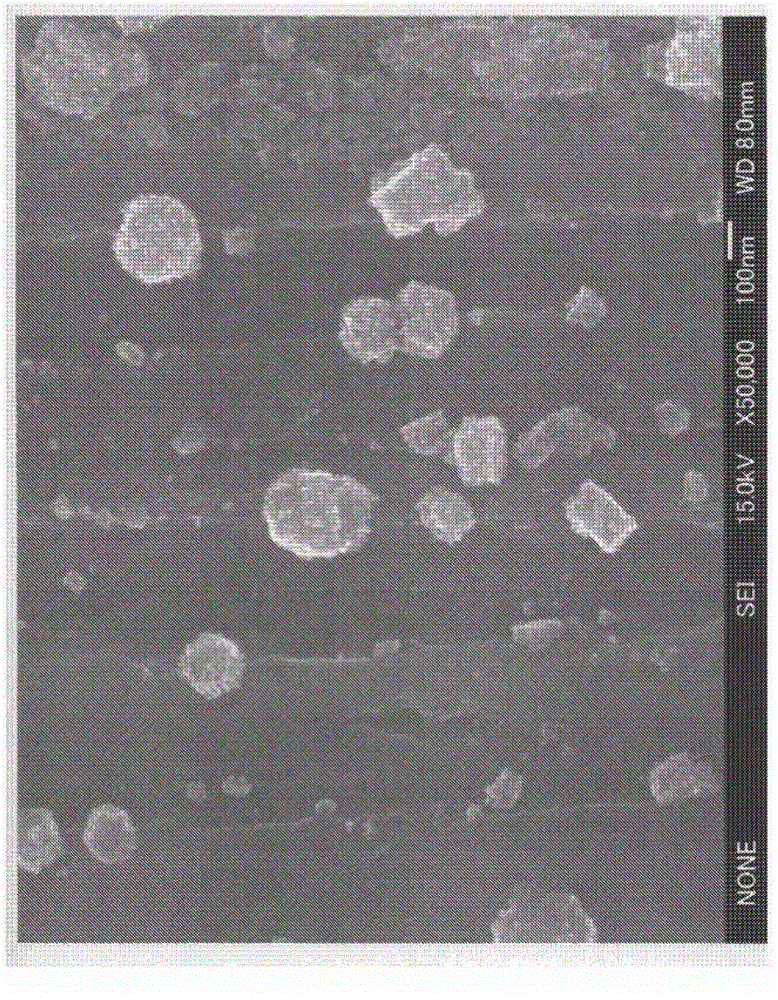

[0040] In this embodiment, silver chloride is dissolved in an aqueous solution of sodium thiosulfate by a common method, diluted with pure water appropriately so that the silver concentration becomes 500-2000 ppm, and 10-20 ppm of amino acid (L-propionic acid) is added to prepare Silver nanocluster (silver complex) aqueous solution (colorless and transparent). Next, on a brass (Cu60; Sn40) substrate with a clean surface, silver nanocluster aqueous solution (10 μL) was added dropwise at intervals, and after 3 minutes, blown with nitrogen gas to dry the water droplets, and the surface plasmon resonance excited SERS was prepared. substrate. figure 2 A scanning electron micrograph (20,000 magnifications) showing the state of the surface formed on the substrate. Such as figure 2 As shown, hexagonal plate crystals of 100-150 nm are formed. In addition, when the crystal formed on the phosphor bronze substrate was observed with a scanning electron microscope (50,000 and 200,000 m...

Embodiment 2

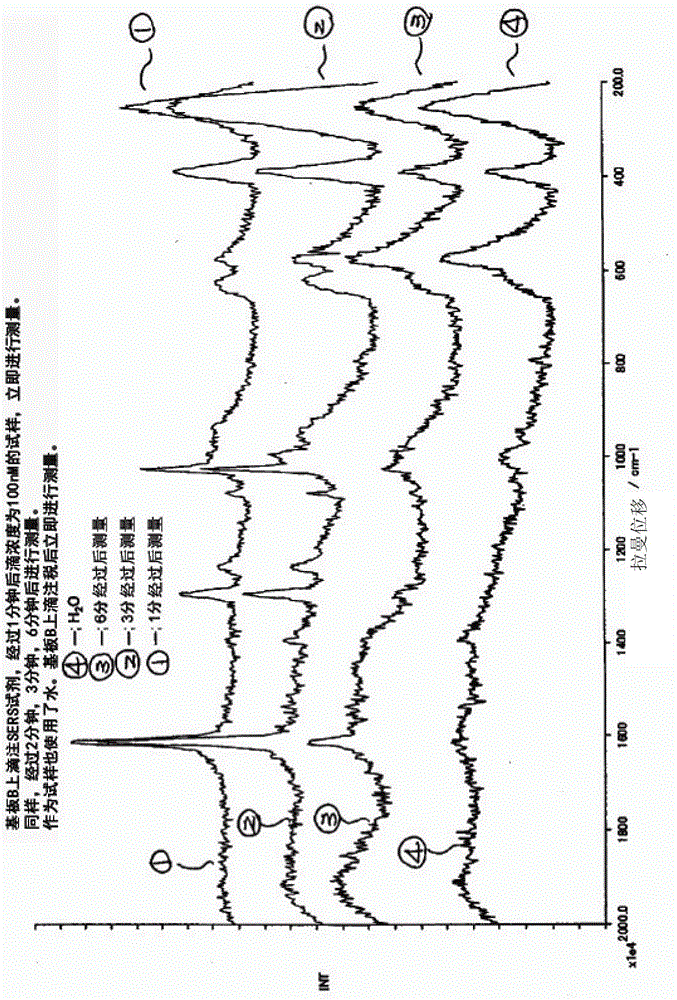

[0042] Prepare a 1000ppm (silver weight conversion) silver complex solution of silver nitrate by a common method, drop it on the phosphor bronze substrate, and spray it with nitrogen gas after 3 minutes to stop the aggregation. Pure water and 4,4-linked Pyridine was diluted to 100nM with pure water and dropped on each substrate, and the Raman spectrometer of Japan Co., Ltd. LAMBDA VISION was used to measure the surface plasmon with a laser with a wavelength of 785nm (laser output power 80mmW, spot size 50μΦ) as excitation light. Somatokinon enhancement effect. As a result, the Raman scattering spectrum was confirmed up to 100 nM (see FIGS. 4( a ) and ( b )).

Embodiment 3

[0044] Change the tested sample to Rhodamine 6G. Do not use amino acid, utilize common method to prepare silver thiosulfate (complex aqueous solution 100ppm, and utilize this silver thiosulfate complex aqueous solution to prepare measurement substrate on phosphor bronze plate as embodiment 1, and rhodamine A 6G (R6G) aqueous solution was dropped on the measurement substrate and measured. As a result, a Raman spectrometer of Kaiser Corporation was used to irradiate a laser with an excitation wavelength of 514 nm, and a Raman spectrum of 1 μM was confirmed ( Figure 5 ). In the past Raman scattering spectrum confirmed by Dr. Papnin using the substrate prepared by the vapor deposition method, only the Raman spectrum of 100 μM was confirmed, so it is certain that the enhancement effect of 100 times was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com