Lactic acid-amino acid copolyester amide and preparation method thereof

A polyester amide and amino acid technology, which is applied in the field of copolyester amide, can solve the problems of low material strength, poor thermal stability, and limitations, and achieve the effects of excellent physical properties, improved performance, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

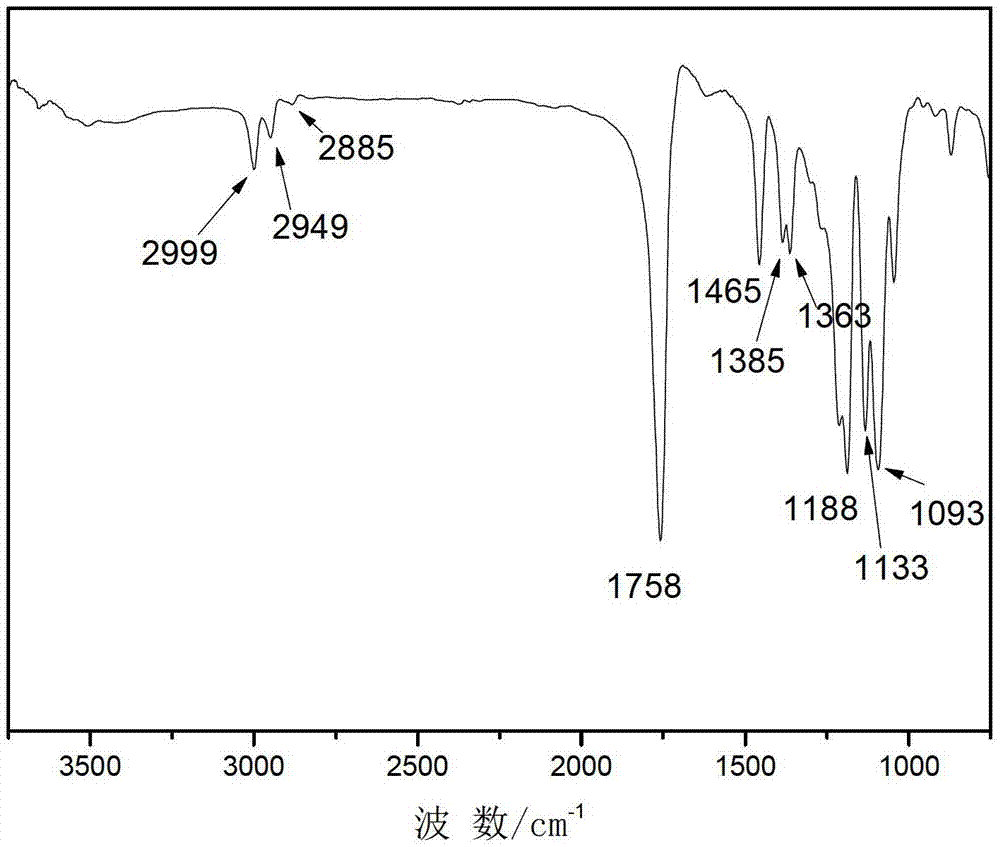

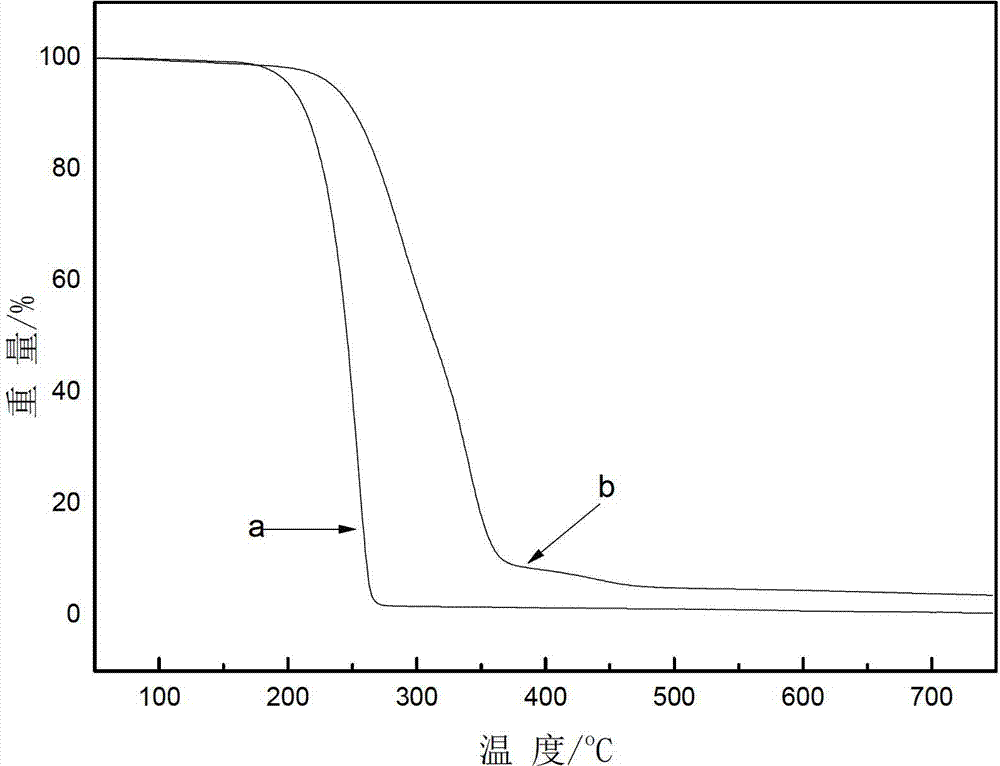

[0024] Preparation of Lactic Acid-5wt% Amino Undecanoic Acid Copolyester Amide by In Situ Melt Polycondensation

[0025] First mix the weighed L-lactic acid and aminoundecanoic acid (5wt%), heat and stir at 100°C for 2 hours; then add the mixture into the reaction bottle, and the amount of addition should not exceed 2 / 3 of the volume. Replace the air in the bottle with nitrogen for 4-5 times, connect the vacuum device, heat to 130°C, depressurize to 100 Torr (Torr), stir at 400r / min, react for 3h; then raise the temperature to 150°C, depressurize to 10 Torr (Torr), reacted for 4h, obtained viscous lactic acid-aminoundecanoic acid oligomer; in the oligomer obtained before, add 0.4wt% composite binary catalyst tin protochloride (SnCl 2 ) and p-toluenesulfonic acid (TSA), SnCl 2 The molar ratio with TSA is 1:1, then gradually heated to 190°C, the pressure dropped to 10 Torr (Torr) in 1.5h, and reacted under this condition for 10h.

[0026] The reaction formula is as follows:

...

Embodiment 2

[0036] Preparation of Lactic Acid-20wt% Amino Undecanoic Acid Copolyester Amide by In Situ Melt Polycondensation

[0037] First mix the weighed L-lactic acid and aminoundecanoic acid (20wt%), heat and stir at 110°C for 2 hours; then add the mixture into the reaction bottle, and the amount of addition should not exceed 2 / 3 of the volume. Replace the air in the bottle with nitrogen for 4-5 times, connect the vacuum device, heat to 140°C, decompress to 100 Torr (Torr), stir at 400r / min, and react for 3h; then the temperature rises to 170°C, and the pressure is reduced to 10 Torr (Torr), reacted for 4h to obtain a viscous lactic acid-aminoundecanoic acid oligomer; in the oligomer obtained before, add 0.6wt% composite binary catalyst stannous chloride (SnCl2) and p-toluene Sulfonic acid (TSA), SnCl 2 The molar ratio with TSA is 1:1, then gradually heated to 200°C, the pressure dropped to 10 Torr (Torr) in 1.5h, and reacted for 10h under this condition.

[0038] The Mw of the lact...

Embodiment 3

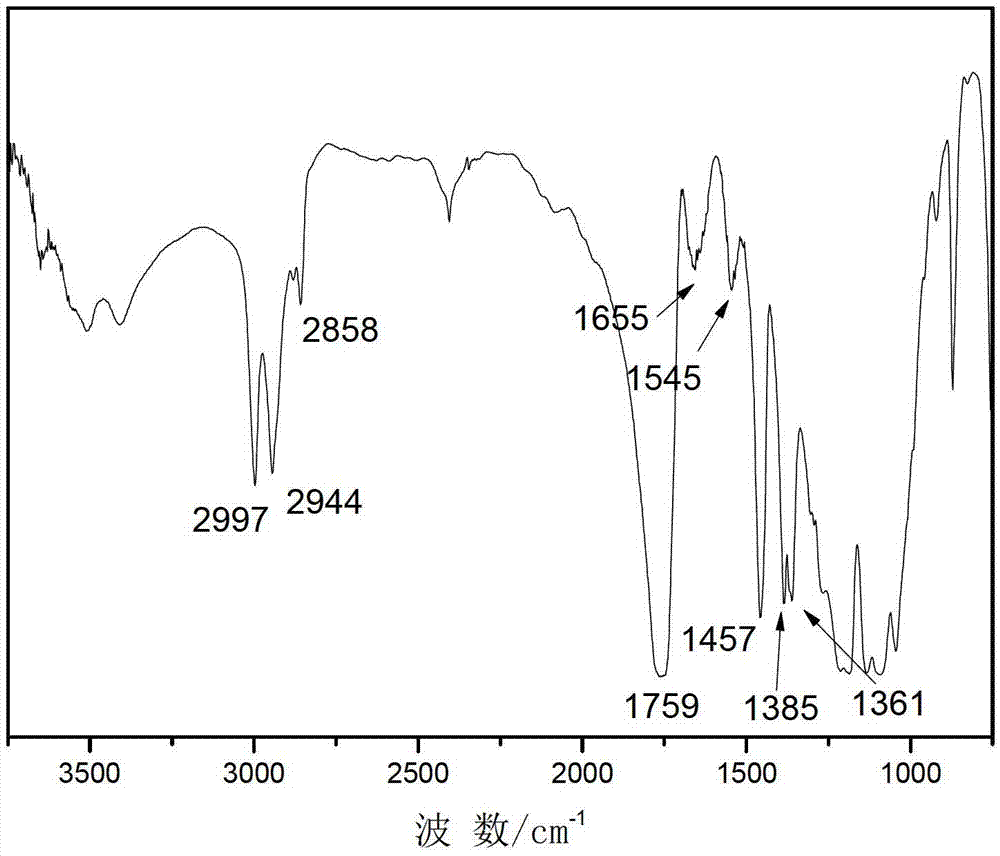

[0040] Preparation of lactic acid-20wt% aminopropionic acid copolyesteramide by in-situ melt polycondensation

[0041]First mix the weighed L-lactic acid and aminopropionic acid (20wt%), heat and stir at 110°C for 2 hours; then add the mixture into the reaction bottle, and the amount of addition should not exceed 2 / 3 of the volume. Replace the air in the bottle with nitrogen for 4-5 times, connect the vacuum device, heat to 130°C, depressurize to 100 Torr (Torr), stir at 400r / min, react for 3h; then raise the temperature to 150°C, depressurize to 10 Torr (Torr), reacted for 4h to obtain a viscous lactic acid-alanine oligomer; in the oligomer obtained before, add 0.6wt% composite binary catalyst tin protochloride (SnCl2) and p-toluenesulfonate acid (TSA), SnCl 2 The molar ratio with TSA is 1:1, then gradually heated to 200°C, the pressure dropped to 10 Torr (Torr) in 1.5h, and reacted for 10h under this condition.

[0042] The reaction formula is as follows:

[0043]

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com