Anti-stress relaxation beryllium free copper alloy with high strength and high elasticity as well as preparation and processing methods thereof

A technology of beryllium copper alloy and processing method, which is applied in the field of high strength, high elasticity, stress relaxation resistance, beryllium copper alloy and its preparation and processing, can solve the problems of high environmental protection requirements, long production process, high production cost, etc., and achieve machinable Excellent performance, reduced production energy consumption, high fatigue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

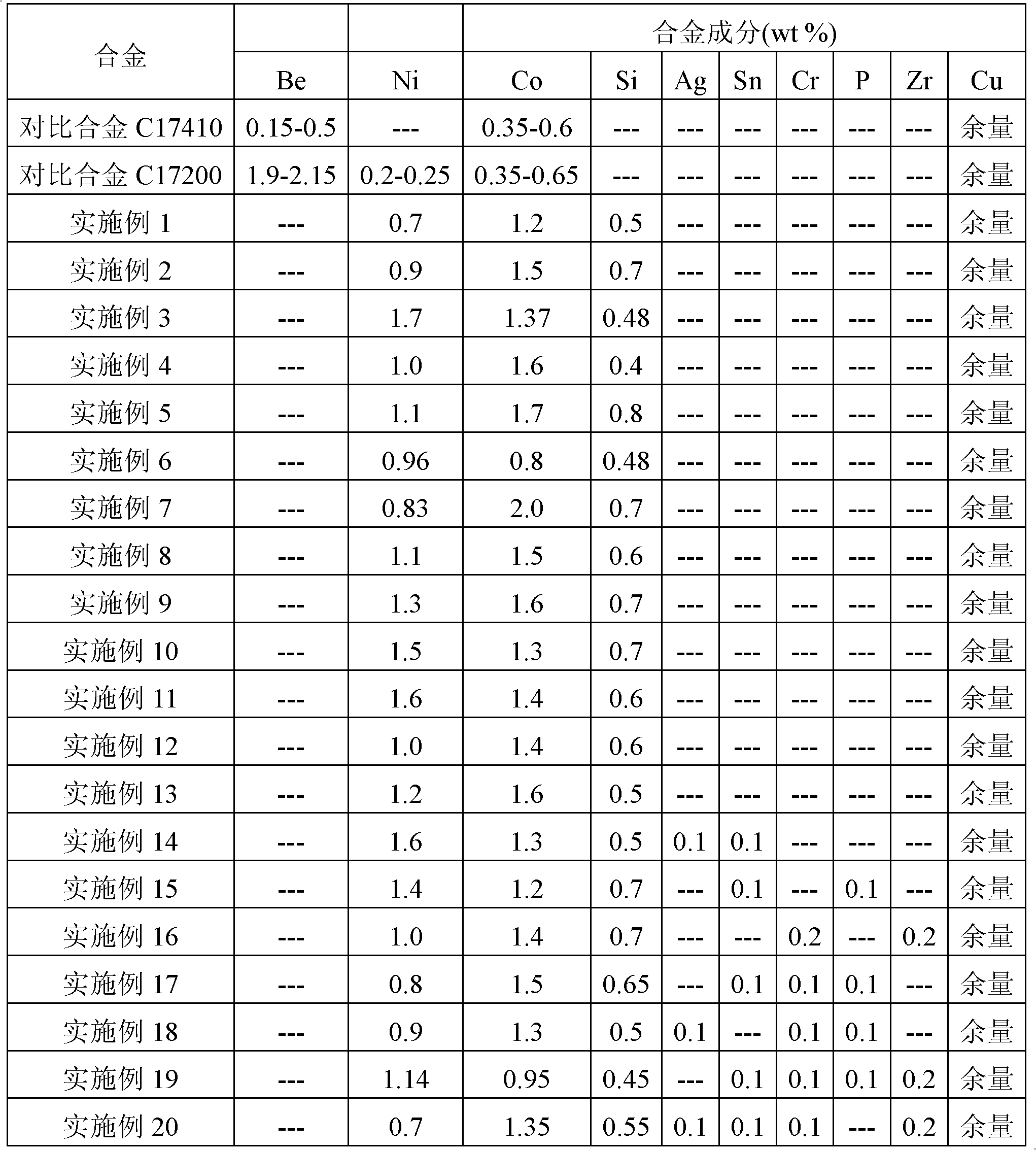

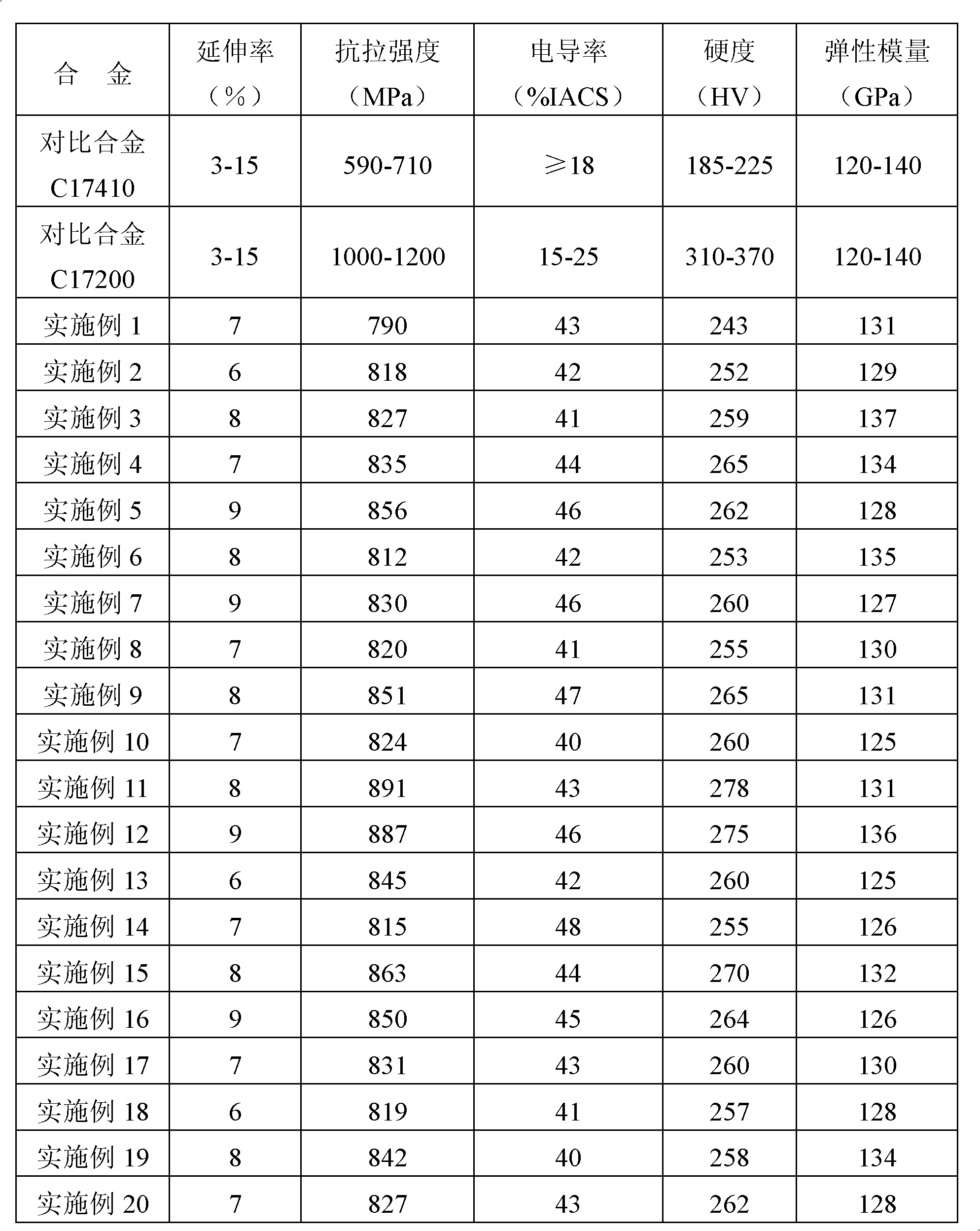

[0029] The alloy of the invention is smelted using the following raw materials: electrolytic copper, pure nickel, cobalt powder and pure silicon. The composition of the alloy is shown in Example 1 of Table 1.

[0030] 1. Melting: use non-vacuum induction furnace for melting. The order of adding the alloy is: first add Cu, after melting, then add Ni and Si, add covering agent (charcoal) and keep warm for 5-10min, after fully degassing and removing impurities, then cover with burning charcoal about 10mm thick. Then add cobalt powder (covered with copper foil), the melting temperature is 1280°C, keep the temperature for 10 minutes, let it stand for 5-10 minutes, and then cast it out of the furnace, the casting temperature is 1200°C.

[0031] 2. Face milling: face milling of the alloy (2mm milling on the upper and lower surfaces, 1mm milling on the left and right sides).

[0032] 3. Hot rolling: the alloy is heated, the heating temperature is 970° C., the holding time is 2 hours...

Embodiment 2

[0040] The alloy of the invention is smelted using the following raw materials: electrolytic copper, pure nickel, cobalt powder and pure silicon. The composition of the alloy is shown in Example 2 of Table 1.

[0041] 1. Melting: use non-vacuum induction furnace for melting. The order of adding the alloy is: first add Cu, after melting, then add Ni and Si, add covering agent (charcoal) and keep warm for 5-10min, after fully degassing and removing impurities, then cover with burning charcoal about 10mm thick. Then add cobalt powder (covered with copper foil), the melting temperature is 1250°C, keep the temperature for 10 minutes, let it stand for 5-10 minutes, and then cast it out of the furnace, the casting temperature is 1150°C.

[0042] 2. Face milling: face milling of the alloy (2mm milling on the upper and lower surfaces, 1mm milling on the left and right sides).

[0043] 3. Hot rolling: the alloy is heated, the heating temperature is 950° C., the holding time is 2.5 hou...

Embodiment 3

[0051] The alloy of the invention is smelted using the following raw materials: electrolytic copper, pure nickel, cobalt powder and pure silicon. The composition of the alloy is shown in Example 3 of Table 1.

[0052] 1. Melting: use non-vacuum induction furnace for melting. The order of adding the alloy is: first add Cu, after melting, then add Ni and Si, add covering agent (charcoal) and keep warm for 5-10min, after fully degassing and removing impurities, then cover with burning charcoal about 10mm thick. Then add cobalt powder (covered with copper foil), the melting temperature is 1300°C, hold the temperature for 10 minutes, let it stand for 5-10 minutes, and then cast it out of the furnace, the casting temperature is 1200°C.

[0053] 2. Face milling: face milling of the alloy (2mm milling on the upper and lower surfaces, 1mm milling on the left and right sides).

[0054] 3. Hot rolling: the alloy is heated, the heating temperature is 950° C., the holding time is 2.5 hou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com