Preparation method of aminated magnetic graphene

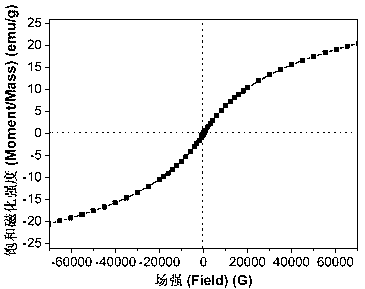

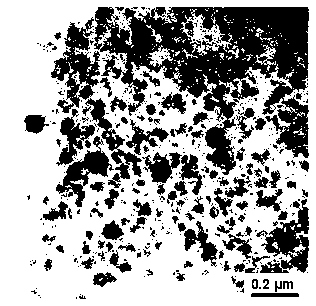

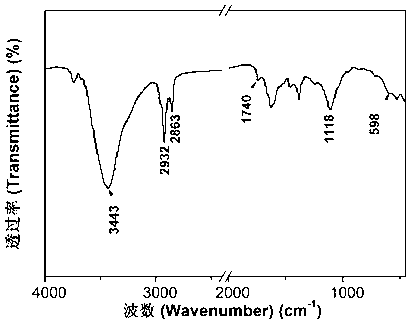

A magnetic graphene, amination technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as reducing the saturation magnetization of composite materials, achieve good superparamagnetic properties, good application prospects, synthesis The effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Add 3 millimoles of ferric chloride to 40 milliliters of graphene oxide solution with a concentration of 4 mg / ml, and stir for 1 hour to prepare a graphene oxide solution containing ferric chloride.

[0018] (2) Add 9 millimoles of dimethylaminoethyl methacrylate to the graphene oxide solution containing ferric chloride prepared in step (1), stir for 30 minutes, and obtain dimethylaminoethyl methacrylate and Graphene oxide mixed solution of ferric chloride.

[0019] (3) the graphene oxide mixed solution containing dimethylaminoethyl methacrylate and ferric chloride that step (2) makes is transferred in the hydrothermal reaction kettle of 100 milliliters, reacts 8 hours at 150 ℃, Then cooled to room temperature, centrifuged and washed with water, then vacuum-dried at 60° C. for 24 hours to prepare aminated magnetic graphene.

Embodiment 2

[0021] (1) Add 4 mmoles of iron sulfate to 40 milliliters of graphene oxide solutions with a concentration of 0.5 mg / ml, and stir for 1.5 hours to obtain a graphene oxide solution containing iron sulfate.

[0022] (2) Add 12 millimoles of diethylaminoethyl methacrylate to the graphene oxide solution containing ferric sulfate prepared in step (1), and stir for 45 minutes to obtain a solution containing diethylaminoethyl methacrylate. and graphene oxide mixed solution of ferric sulfate.

[0023] (3) the graphene oxide mixed solution containing diethylaminoethyl methacrylate and ferric sulfate that step (2) makes is transferred in the hydrothermal reaction kettle of 100 milliliters, reacts 12 hours at 200 ℃, Then cooled to room temperature, centrifuged and washed with water, then vacuum-dried at 60° C. for 24 hours to prepare aminated magnetic graphene.

Embodiment 3

[0025] (1) Add 6 mmoles of ferric nitrate to 40 milliliters of graphene oxide solution with a concentration of 6 mg / ml, and stir for 2 hours to prepare a graphene oxide solution containing ferric nitrate.

[0026] (2) Add 25 millimoles of dimethylaminoethyl acrylate to the graphene oxide solution containing ferric nitrate prepared in step (1), stir for 120 minutes to obtain dimethylaminoethyl acrylate and ferric nitrate Graphene oxide mixed solution.

[0027] (3) Transfer the graphene oxide mixed solution containing dimethylaminoethyl acrylate and ferric nitrate prepared in step (2) into a 100 ml hydrothermal reactor, react at 160°C for 16 hours, and then cool to room temperature, centrifuged and washed with water, then vacuum-dried at 60° C. for 24 hours to prepare aminated magnetic graphene.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com