Ecological environment-friendly dust inhibitor

An environmentally friendly and inhibitory technology, applied in other chemical processes, chemical instruments and methods, etc., can solve problems such as pollution, driving safety threats, and aggravated compaction, and achieve huge economic benefits, wide applicability, and soil improvement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

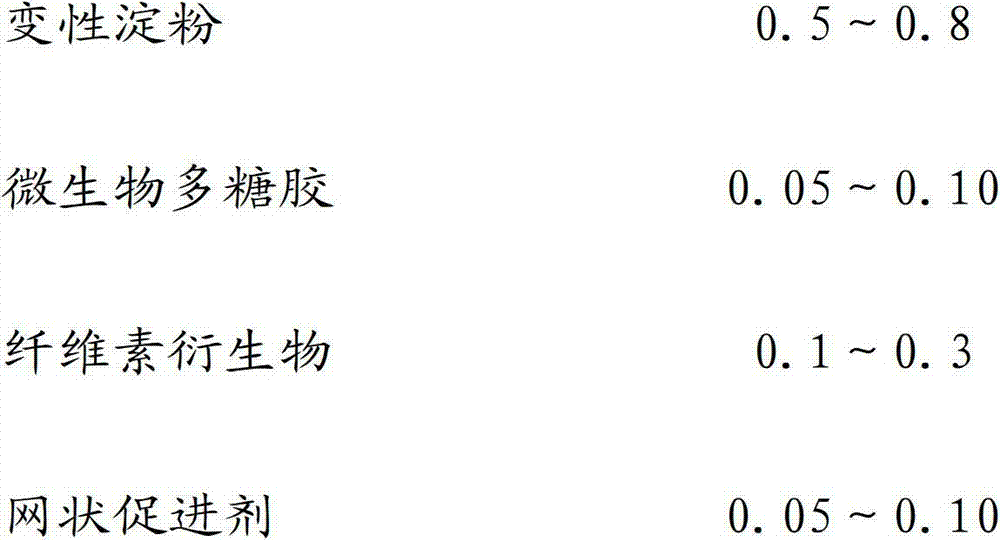

[0043] In the preparation tank, first add 439.7kg tap water, turn on the stirring, then add 3.5kg pregelatinized starch, 0.4kg gellan gum, 1.0kg sodium carboxymethyl cellulose, 0.25kg aluminum chloride, 0.4kg sodium aluminosilicate, 0.25kg polyvinyl alcohol, stir for 1.5h to fully dissolve the materials to obtain the finished product.

Embodiment 2

[0045] In the preparation tank, first add 494.05kg tap water, turn on the stirring, and then add 3.0kg pregelatinized starch, 0.35kg xanthan gum, 1.5kg sodium hydroxyethylcellulose, 0.35kg sodium titanate, 0.45kg glucose, 0.30kg polymer Acrylamide, stir for 1.5h to fully dissolve the materials to obtain the finished product.

Embodiment 3

[0047] In the preparation tank, first add 493.55kg tap water, turn on the stirring, then add 4.0kg pregelatinized starch, 0.25kg pullulan, 1.25kg sodium hydroxypropyl methylcellulose, 0.25kg sodium tetraborate, 0.4kg gas phase Silica, 0.3kg polyvinyl alcohol, stir for 1.5h to fully dissolve the materials to obtain the finished product.

[0048] The gum used in existing dust inhibitor products is generally plant seed gum. Compared with the performance of the microbial polysaccharide gum used in the present invention, it has the following differences:

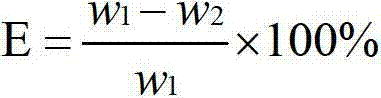

[0049]

[0050]

[0051] It can be seen from the above table that the microbial polysaccharide gum dust suppressant has higher heat resistance, acid and alkali resistance, salt tolerance, enzymatic resistance and wider applicability than the plant seed gum dust suppressant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com