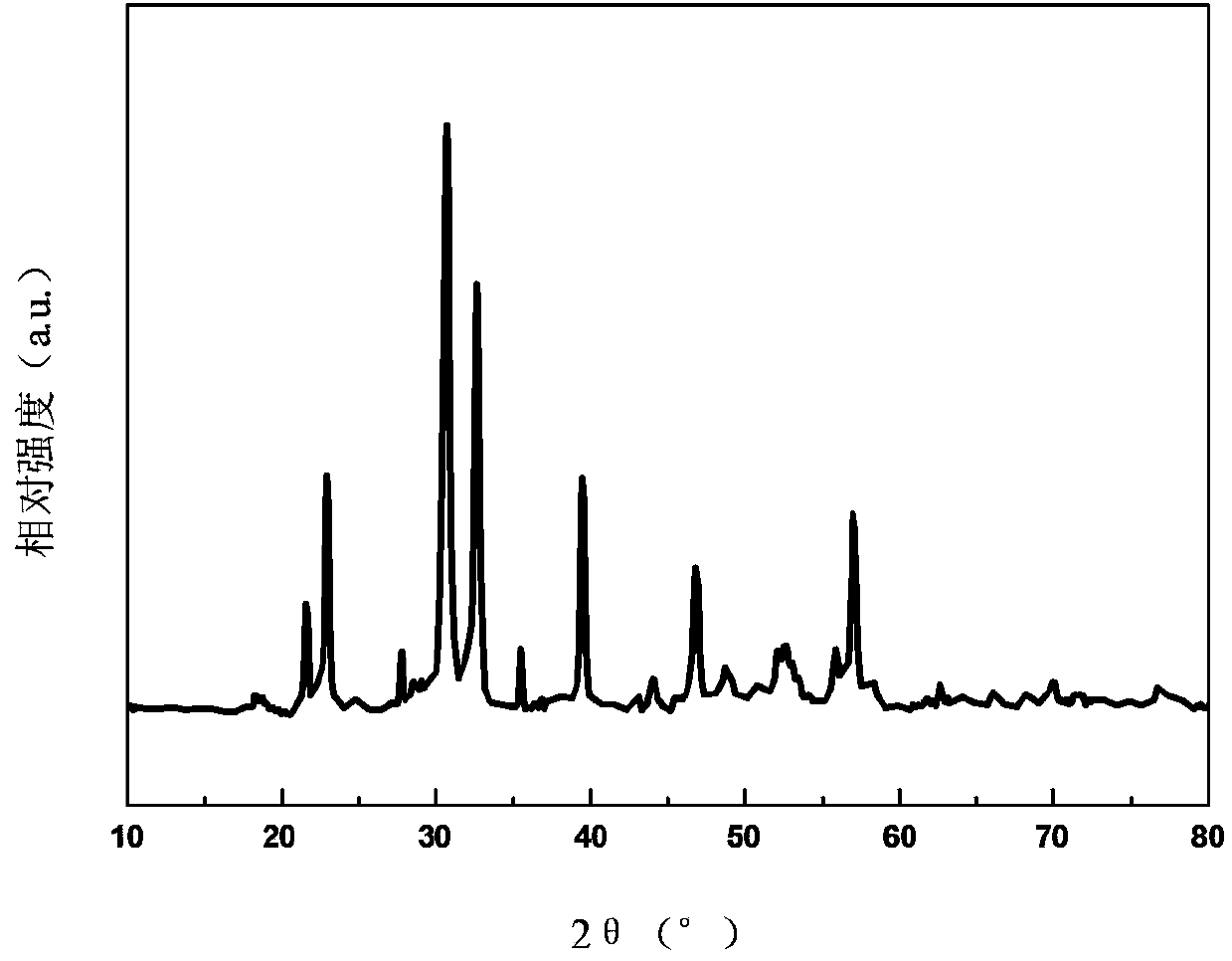

Nine-layer-structure titanium iron bismuth cobalt oxide multiferroic ceramic material and preparation method thereof

A technology of bismuth iron cobaltate and ceramics, which is applied in the field of nine-layer layered bismuth titanium iron cobaltate ceramic materials and its preparation, can solve the problems of unevenness, long experiment period, high reaction temperature, etc., and achieve improved ferromagnetic properties, Improved electrical performance and low burn-in temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

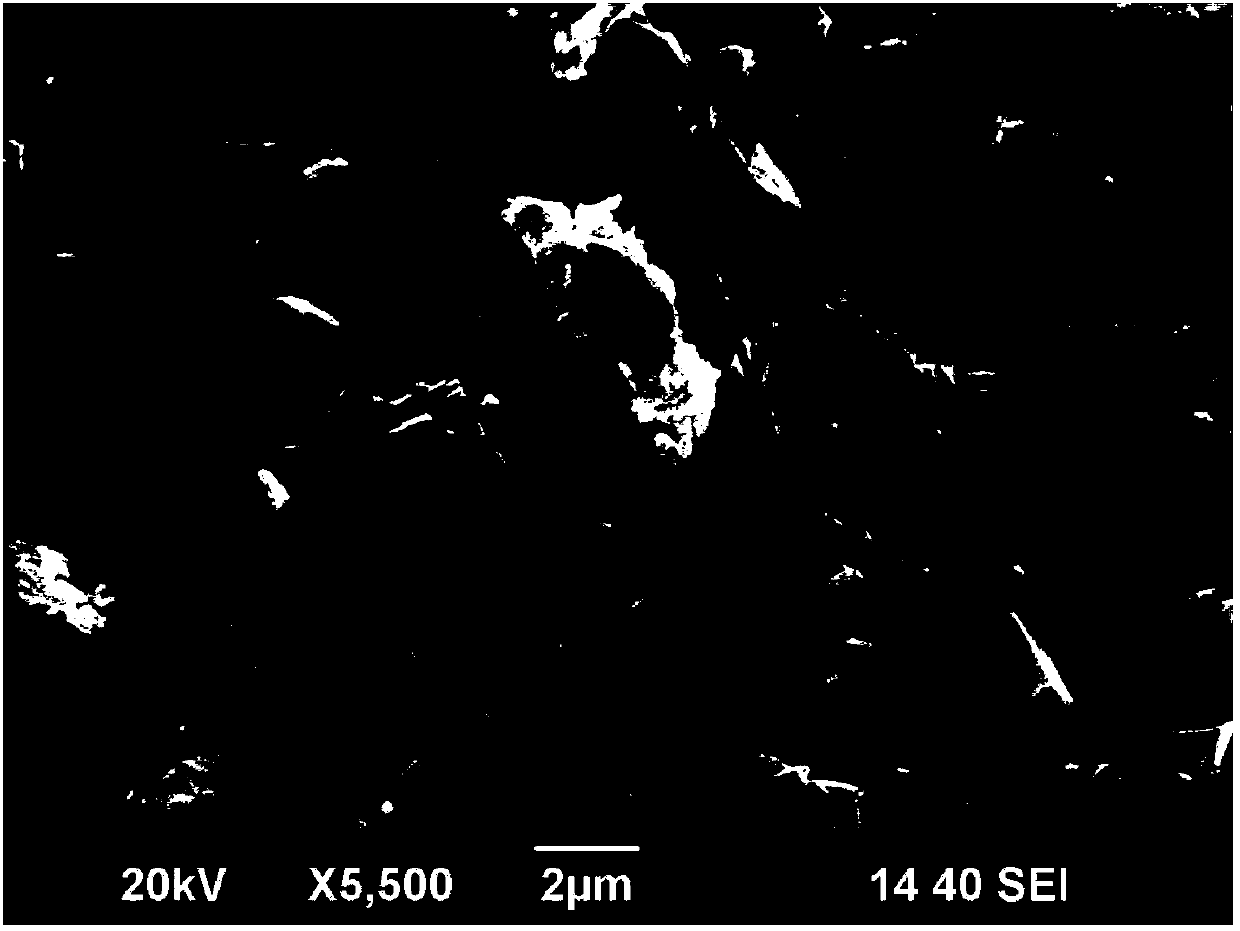

Embodiment 1

[0016] According to the purity of each raw material listed in Table 1 and its weighing amount, get chemically pure n-butyl titanate (C 16 h 36 o 4 Ti), analytically pure bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), analytically pure ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and analytically pure cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 (0) is a raw material, after being accurately weighed in a molar ratio of 3:10:5:1, it is dissolved in 100ml mass percent concentration and is 80% nitric acid aqueous solution, and a complexing agent composed of ethylenediaminetetraacetic acid and citric acid is added. The amount to be added is such that the molar ratio of ethylenediaminetetraacetic acid and citric acid in the complexing agent to the metal ions contained in the solution is 0.7:1:1, and stirred at a constant speed until a clear solution is formed.

[0017] The purity and usage amount of concrete various raw materials are shown in the following table 1 ...

Embodiment 2

[0028] According to the requirements of each raw material purity listed in Table 2 and its weighing quality, get chemically pure n-butyl titanate (C 16 h 36 o 4 Ti), analytically pure bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), analytically pure ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) and analytically pure cobalt nitrate hexahydrate (Co(NO 3 ) 2 ·6H 2 (0) is a raw material, after being accurately weighed in a molar ratio of 3:10:5.5:0.5, it is dissolved in 100ml mass percent concentration and is 70% nitric acid aqueous solution, and a complexing agent composed of ethylenediaminetetraacetic acid and citric acid is added, and Add the amount so that the molar ratio of ethylenediaminetetraacetic acid, citric acid in the complexing agent and the metal ions contained in the solution is 0.5:1:1, and stir at a constant speed until a clear solution is formed.

[0029] The purity and consumption of concrete various raw materials are shown in the following table...

Embodiment 3

[0040] According to the requirements of each raw material purity listed in Table 3 and its weighing quality, get chemically pure n-butyl titanate (C 16 h 36 o 4 Ti), analytically pure bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O) and analytically pure ferric nitrate nonahydrate (Fe(NO 3 ) 3 9H 2 O) as a raw material, after being accurately weighed in a molar ratio of 3:10:6, it is dissolved in 100ml of a mass percentage concentration of 90% nitric acid aqueous solution, and a complexing agent composed of ethylenediaminetetraacetic acid and citric acid is added, the amount of Make the molar ratio of ethylenediaminetetraacetic acid in the complexing agent, citric acid and the metal ions contained in the solution to be 1:1:1, and stir at a constant speed until a clear solution is formed.

[0041] The purity and consumption of concrete various raw materials are shown in the following table 3 in the present embodiment:

[0042] Prepare Bi in the embodiment 3 of table 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com