Icing-proof coating with low ice adhesion, and preparation method and application thereof

An anti-icing and adhesion technology, used in coatings, devices for coating liquids on surfaces, etc., can solve the problems of large labor and material resources, limited temperature range, reduced anti-icing and frost resistance, etc., to improve mechanical performance and resistance. Abrasiveness, good mechanical properties, and the effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

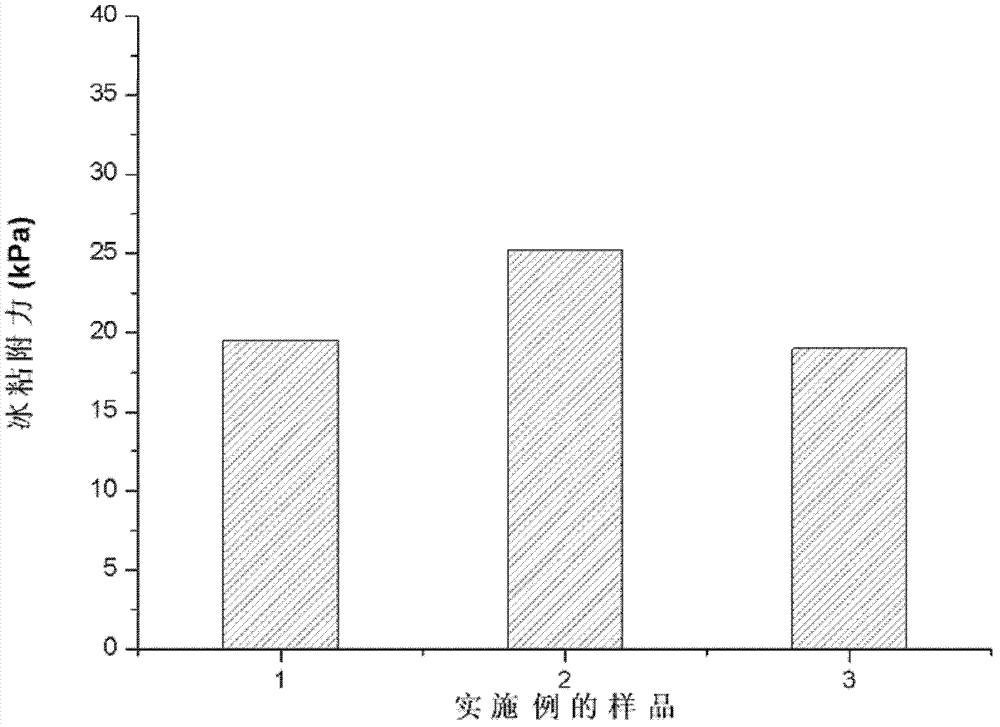

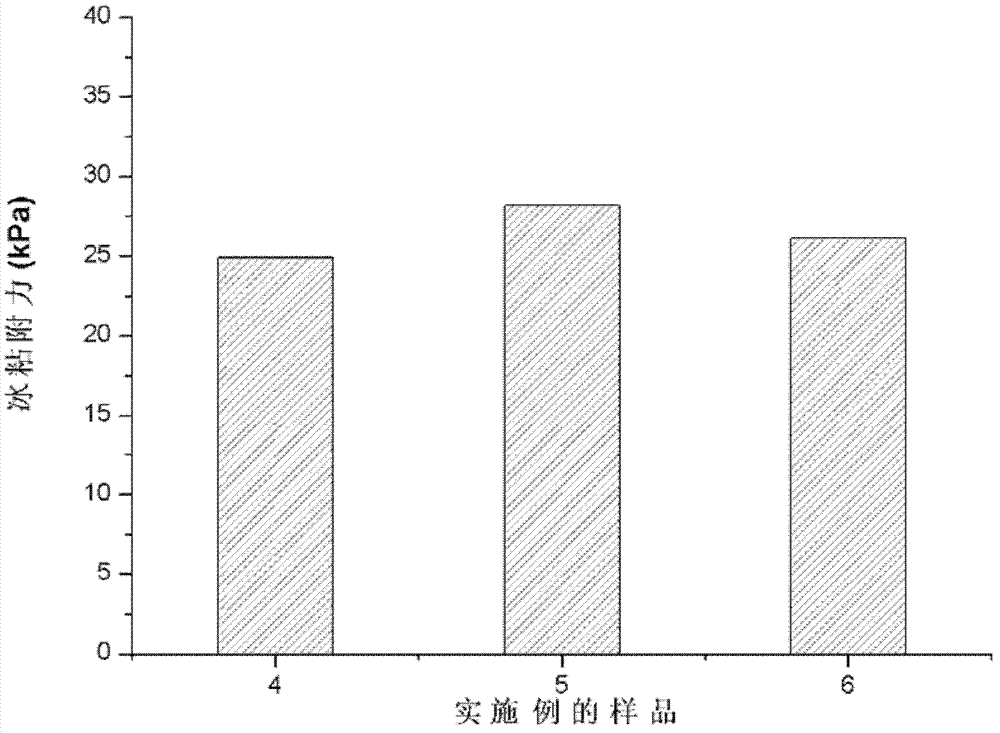

Embodiment 1

[0041] (1), preparation of cross-linked hydrophilic polyelectrolyte

[0042] The mass fraction is 30% acrylic acid, 5% divinylbenzene, 5% vinyl trimethoxysilane, 0.1% phenyl bis(2,4,6-tri Toluyl) phosphine oxide was dissolved in the remaining amount of methanol, after stirring evenly, at 10mw / cm 2 Under light conditions (wavelength: 365nm), free radical polymerization was initiated by phenylbis(2,4,6-trimethylbenzoyl)phosphine oxide for 15 minutes to obtain cross-linked polyacrylic acid.

[0043] (2), preparation of anti-icing coating

[0044] The anti-icing coating is obtained by mixing 30% of diatomite and 70% of the total mass of the anti-icing coating with the cross-linked polyacrylic acid prepared in step (1) and ball milling for 48 hours.

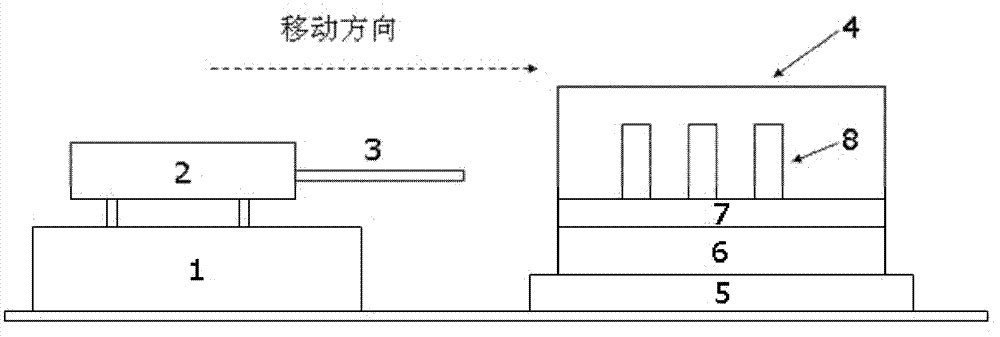

[0045] (3) Application of anti-icing coating

[0046] The anti-icing coating prepared in step (2) is directly coated on the surface of the aluminum sheet and dried to form a film. After being dried and formed into a film, it is pla...

Embodiment 2

[0049] (1), preparation of cross-linked hydrophilic polyelectrolyte

[0050] The mass fraction is 40% vinylbenzene sulfonic acid, the mass fraction is 5% diphenylmethane diisocyanate, the mass fraction is 5% vinyltriethoxysilane, and the mass fraction is 0.2% 2-hydroxyl-2 -Methyl-1-phenylacetone was dissolved in the remaining amount of ethanol, after stirring evenly, at 20mw / cm 2 Under light conditions (wavelength: 365 nm), free radical polymerization was initiated by 2-hydroxy-2-methyl-1-phenylacetone for 15 minutes to obtain cross-linked polyvinylbenzenesulfonic acid.

[0051] (2), preparation of anti-icing coating

[0052] The activated alumina that accounts for 20% of the total mass of the anti-icing coating and the cross-linked polyvinylbenzenesulfonic acid that accounts for 80% of the total mass of the anti-icing coating are mixed and ball milled for 72 hours to obtain the anti-icing coating ice paint.

[0053] (3) Application of anti-icing coating

[0054] The anti-...

Embodiment 3

[0057] (1), preparation of cross-linked hydrophilic polyelectrolyte

[0058] The mass fraction is 60% allylsulfonic acid, the mass fraction is 5% N,N-methylenebisacrylamide, the mass fraction is 5% allyltrimethoxysilane, and the mass fraction is 0.5% 1-Hydroxycyclohexyl phenyl ketone was dissolved in the remaining amount of isopropanol, after stirring evenly, at 30mw / cm 2 Under light conditions (wavelength: 365nm), free radical polymerization was initiated by 1-hydroxycyclohexyl phenyl ketone for 15 minutes to obtain cross-linked polyallyl sulfonic acid.

[0059] (2), preparation of anti-icing coating

[0060] The clay that accounts for 10% of the total mass of the anti-icing coating and the cross-linked polyallyl sulfonic acid that accounts for 90% of the total mass of the anti-icing coating are mixed and ball milled for 120 hours to obtain the anti-icing coating .

[0061] (3) Application of anti-icing coating

[0062] The anti-icing coating prepared in step (2) is direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com