Method for preparing magnesium-lithium alloy surface micro-arc oxidation self-assembling super hydrophobic composite coating

A technology of micro-arc oxidation and magnesium-lithium alloy, which is applied in anodic oxidation and other directions to achieve the effect of improving corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

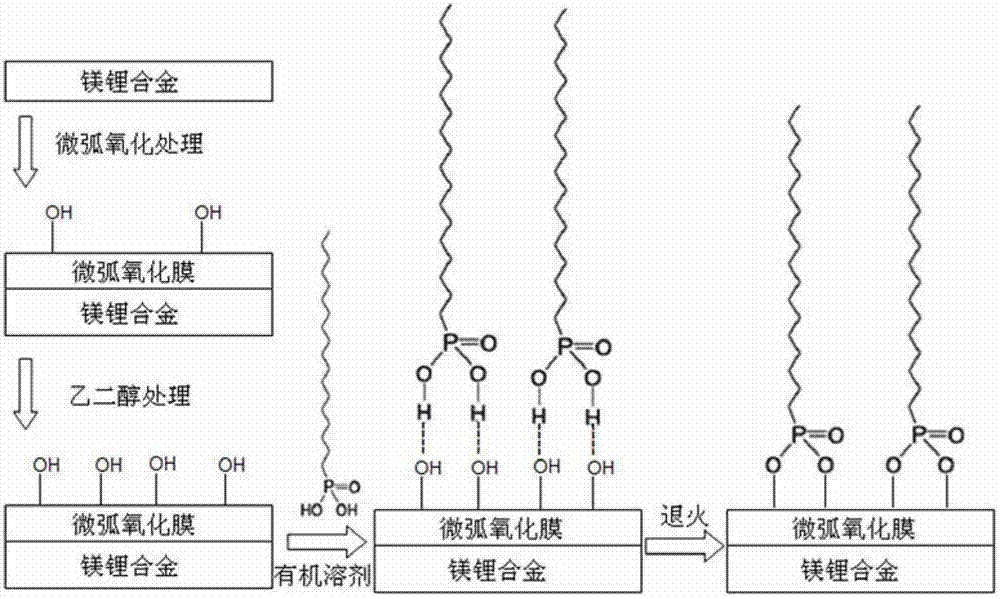

Method used

Image

Examples

specific Embodiment approach 1

[0032] (1) Pretreatment

[0033] In order to obtain a film with good adhesion, a series of pre-treatment work must be carried out, such as grinding, surface degreasing and cleaning, ultrasonic cleaning, in order to obtain a clean alloy surface.

[0034] The specific pretreatment process is to grind the sample with 240#, 400#, 1000#, 2000# sandpaper in sequence, immerse in acetone solution for ultrasonic treatment for 10-20 minutes, then rinse with distilled water, dry it, and put it in a desiccator for later use .

[0035] (2) Micro-arc oxidation

[0036] Electrolyte composition: silicate 5-20g / L, sodium hydroxide 2-8g / L, triethanolamine 5-20g / L. Add the weighed medicines into a beaker filled with a certain amount of distilled water in turn, and stir continuously to dissolve it, and finally add distilled water to dilute to the required concentration. Connect the pre-treated magnesium-lithium alloy with an aluminum wire and put it into a stainless steel electrolytic cell as ...

specific Embodiment approach 2

[0039] (1) Pretreatment of magnesium-lithium alloy surface

[0040] The magnesium-lithium alloy substrate is pre-treated by grinding, surface degreasing and cleaning, and ultrasonic cleaning.

[0041] (2) Micro-arc oxidation

[0042] The pretreated magnesium-lithium alloy is placed in the alkaline silicate electrolyte system, and the plasma electrolytic oxidation treatment is carried out by means of DC pulse output; the pulse frequency is 1000-2000Hz, the duty ratio is 5-20%, and the current density is 3- 8A / cm 2 , Processing time 5-10 minutes. The samples after micro-arc oxidation treatment were rinsed with deionized water, dried, and placed in a desiccator for later use.

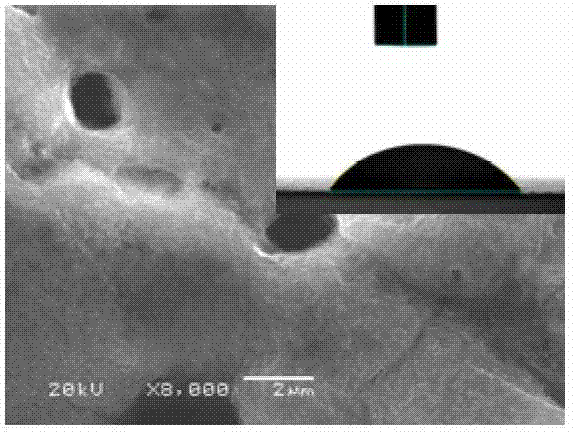

[0043] (3) Construction of superphobic composite coating

[0044] Soak the micro-arc oxidation film in ethylene glycol solution, rinse it with deionized water and ethanol successively after taking it out, place it in an oven to dry, and cool it at room temperature. Then put it into the self-assembly s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com