Conductive polymer composite conductive paper and preparation method and application thereof

A conductive polymer, composite conductive technology, used in paper, paper, textiles and paper making, etc., can solve the problems of poor fiber-to-paper strength, low retention of conductive materials, poor coating adhesion, etc., to achieve strength retention Good, high cost to solve, high conductivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

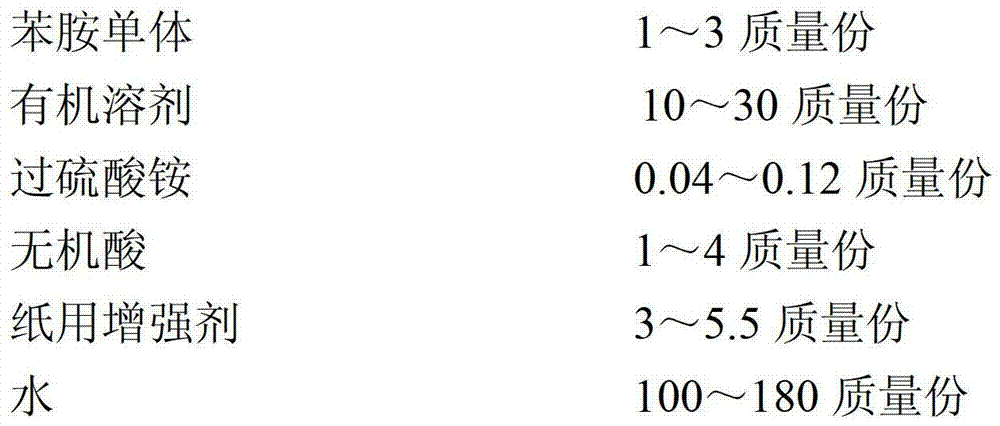

Method used

Image

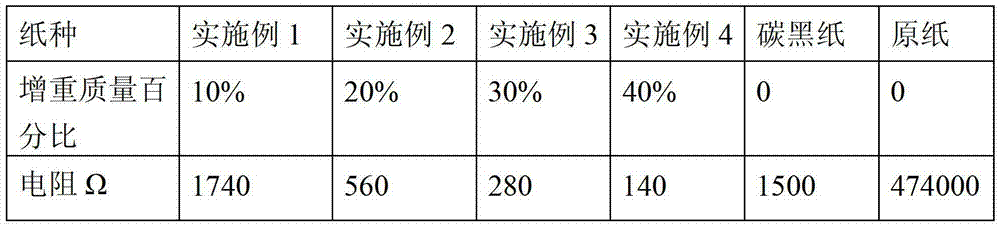

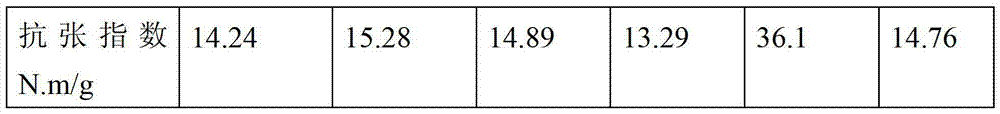

Examples

Embodiment 1

[0038] The preparation method of conductive polymer composite conductive paper of the present invention comprises the following steps:

[0039] (1) 1 mass part of aniline monomer is dissolved in 10 mass parts of acetone;

[0040] (2) Dissolve 0.04 parts by mass of ammonium persulfate in 100 parts by mass of distilled water, add 1 part by mass of hydrochloric acid, and mix well.

[0041] (3) Impregnate 4 parts by mass of paper with reinforcing agent melamine formaldehyde resin MF (for industrial products) to treat the paper substrate (qualitative filter paper, 18CM specification) for 3 minutes, take out and squeeze out excess water, and dry completely at 100°C;

[0042] (4) Drop the solution prepared in step (1) onto the paper substrate treated in step (3) to infiltrate it. Take out and squeeze out the excess liquid, that is, put it in the solution prepared in step (2) for 10 seconds. Take out and squeeze excess water and dry naturally;

[0043] (5) Repeat the step (4) twice ...

Embodiment 2

[0046] The preparation method of conductive polymer composite conductive paper of the present invention comprises the following steps:

[0047] (1) Dissolving 3 parts by mass of aniline monomer in 20 parts by mass of chloroform;

[0048] (2) Dissolve 0.12 parts by mass of ammonium persulfate in 150 parts by mass of distilled water, add 3 parts by mass of sulfuric acid with a mass fraction of 98%, and mix well.

[0049] (3) Impregnate 5.5 parts by mass of paper with the strengthening agent urea-formaldehyde resin UF (for industrial products) to treat the paper substrate (18CM quantitative filter paper) for 10 minutes, take it out and press out the excess water, and dry it completely at 110°C;

[0050] (4) Drop (1) onto the substrate treated in step (3) to infiltrate it, take it out and press out the excess liquid, that is, put it in (2) for 20 seconds, take it out and squeeze out the excess water and dry it naturally;

[0051] (5) Repeat the step (4) three times to obtain cond...

Embodiment 3

[0054] The preparation method of conductive polymer composite conductive paper of the present invention comprises the following steps:

[0055] (1) Dissolving 2 parts by mass of aniline monomer in 30 parts by mass of carbon tetrachloride;

[0056] (2) Dissolve 0.1 part by mass of ammonium persulfate in 100 parts by mass of distilled water, add 2 parts by mass of phosphoric acid, and mix well.

[0057] (3) Impregnate 4 parts by mass of paper with the strengthening agent polyamide epichlorohydrin PAE (for industrial products) to treat the paper substrate (the paper substrate is 18CM qualitative filter paper) for 5 minutes, take out and squeeze out the excess water, and put it at 105°C completely dry;

[0058](4) Drop (1) onto the substrate treated in step (3) to infiltrate it, take it out and press out the excess liquid, that is, put it in (2) for 20 seconds, take it out and squeeze out the excess water and dry it naturally;

[0059] (5) Repeat step (4) 4 times to obtain condu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com