Three-dimensional boron nitride foam and preparation method thereof

A boron nitride, hexagonal boron nitride technology, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., to achieve the effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

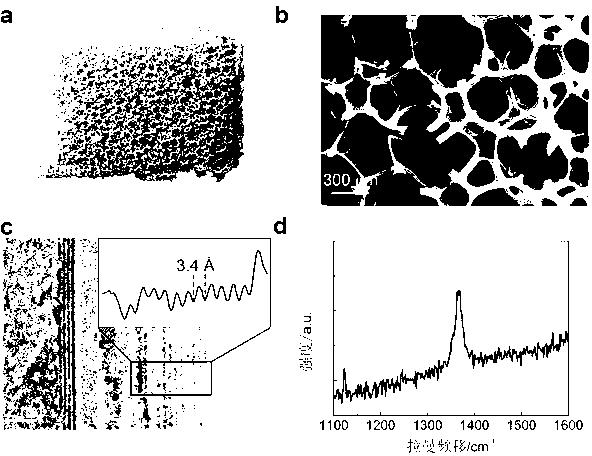

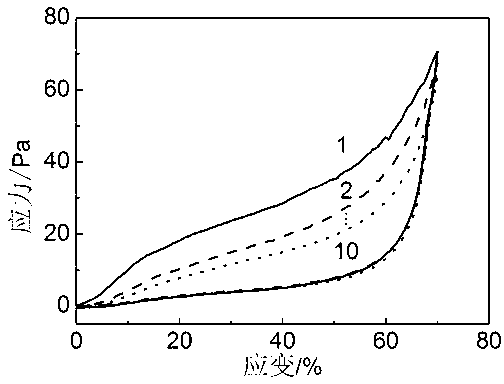

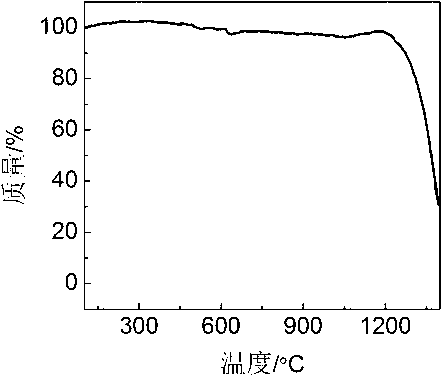

[0023] First, weigh 0.5g of borane ammonium complex and place it in a non-working oven, place nickel foam with a size of 20mm×100mm×1.6mm in the central area of the tube furnace, turn on the vacuum pump, and pass the flow through the flowmeter The hydrogen gas is 10 mL / min, heated to 1000°C at a rate of 10°C / min and kept for 30 minutes, then the oven is heated to 100°C to preheat the reaction source, and the boron nitride film is grown for 60 minutes. After the end, the tube furnace was turned on, and the temperature was rapidly cooled to room temperature at a speed of 100°C / min.

[0024] Then, the anisole solution of polymethyl methacrylate (4wt%) was added dropwise to the surface of foamed nickel with a boron nitride film, dried and placed in a 3mol / L hydrochloric acid solution, and placed at 80°C 10h to dissolve nickel foam. After washing with deionized water, the sample was placed in air at 700°C and heated for 30 min to remove polymethyl methacrylate on the surface of ...

Embodiment 2

[0028] First, weigh 0.5g of borane ammonium complex and place it in a non-working oven, place nickel foam with a size of 50mm×5mm×1.6mm in the central area of the tube furnace, turn on the vacuum pump, and pass the flow through the flow meter The hydrogen gas is 10 mL / min, and the hydrogen gas is heated to 1200°C at a rate of 10°C / min and kept for 30 minutes, then the oven is heated to 120°C to preheat the reaction source, and then the boron nitride film is grown for 60 minutes. After the end, the tube furnace was turned on and cooled slowly to room temperature at a rate of 10°C / min.

[0029] Then, the ethyl lactate solution of polypropylene (2wt%) was added dropwise to the surface of nickel foam with a boron nitride film, dried and placed in a 5mol / L ferric chloride solution, and placed at 90°C for 5h Dissolves nickel foam. After washing with deionized water, the samples were heated in air at 800°C for 10 min to remove the polypropylene on the boron nitride surface.

[00...

Embodiment 3

[0032] First, weigh 0.5g of borane ammonium complex and place it in a non-working oven, place nickel foam with a size of 20mm×100mm×1.6mm in the central area of the tube furnace, turn on the vacuum pump, and pass the flow through the flowmeter It is a mixed gas of hydrogen and argon at 50 mL / min, where the volume ratio of hydrogen is 20%, and the hydrogen is heated to 800°C at a speed of 10°C / min and kept for 30 minutes, and then the temperature of the oven is raised to 80°C to preheat the reaction source. After heating, the boron nitride thin film starts to grow, and the growth time is 120min. After the end, the tube furnace was turned on and cooled slowly to room temperature at a rate of 10°C / min.

[0033] Then, the anisole solution of polystyrene (4wt%) was added dropwise to the surface of nickel foam with a boron nitride film, dried and placed in 1mol / L nitric acid solution, and placed at 60°C for 20h to dissolve the foam nickel. After washing with deionized water, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com