Mobile kitchen garbage solid, oil, water three-phase separation and wastewater purification device

A technology for purifying food waste and waste water, which is applied in the field of water three-phase separation and waste water purification treatment, solid, oil, and mobile devices, which can solve the problem of large equipment footprint, large volume and floor area, and multiple processes And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

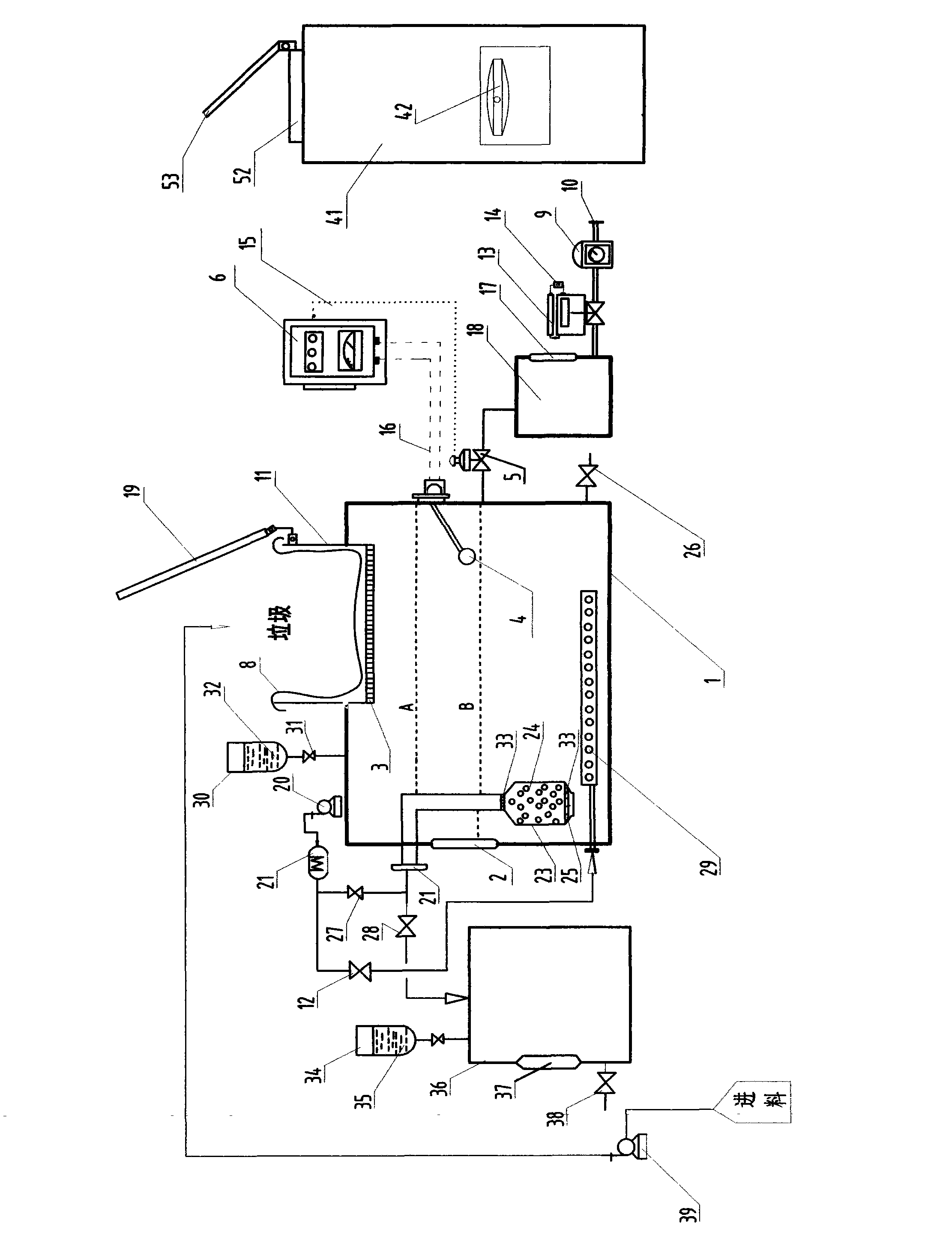

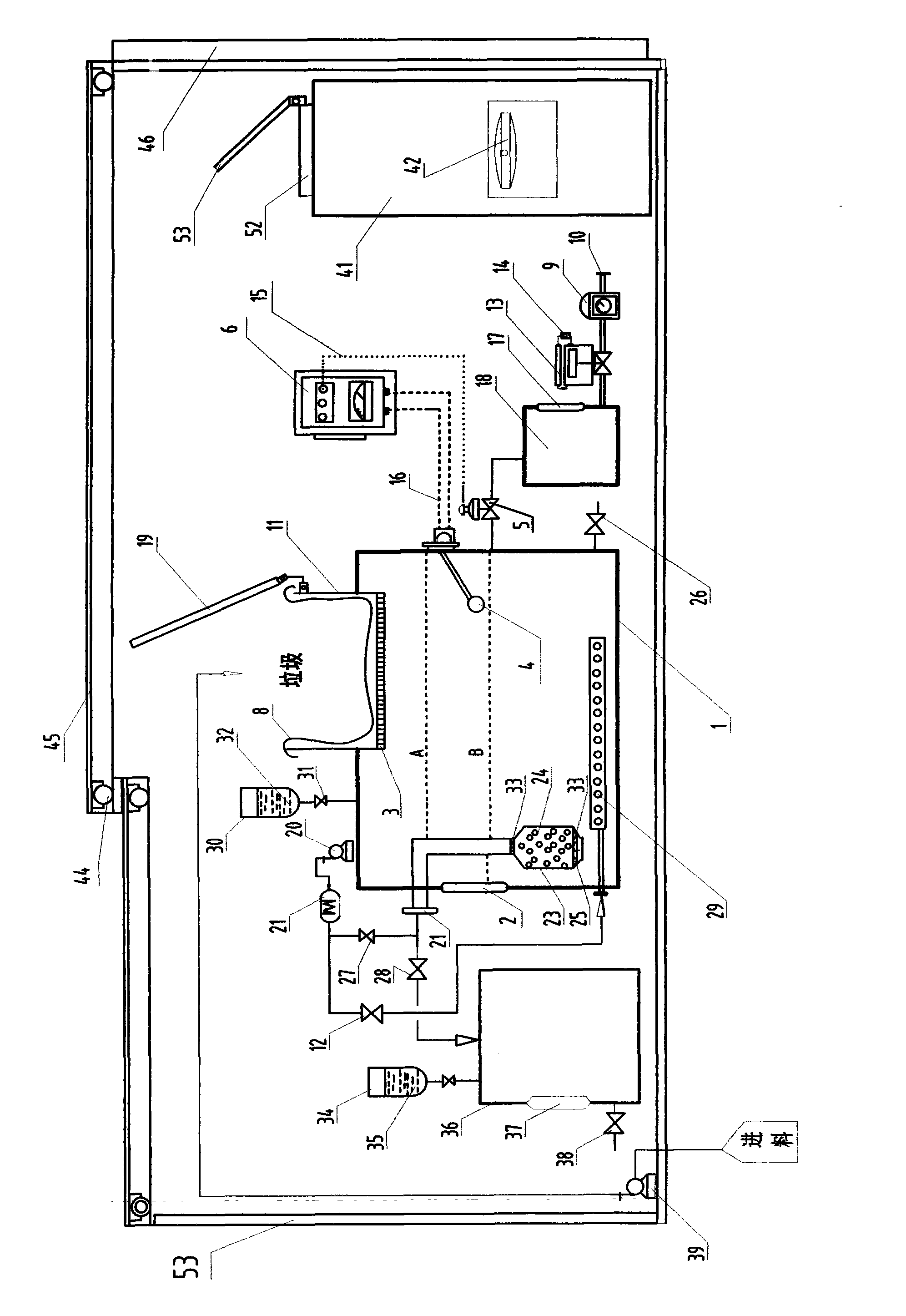

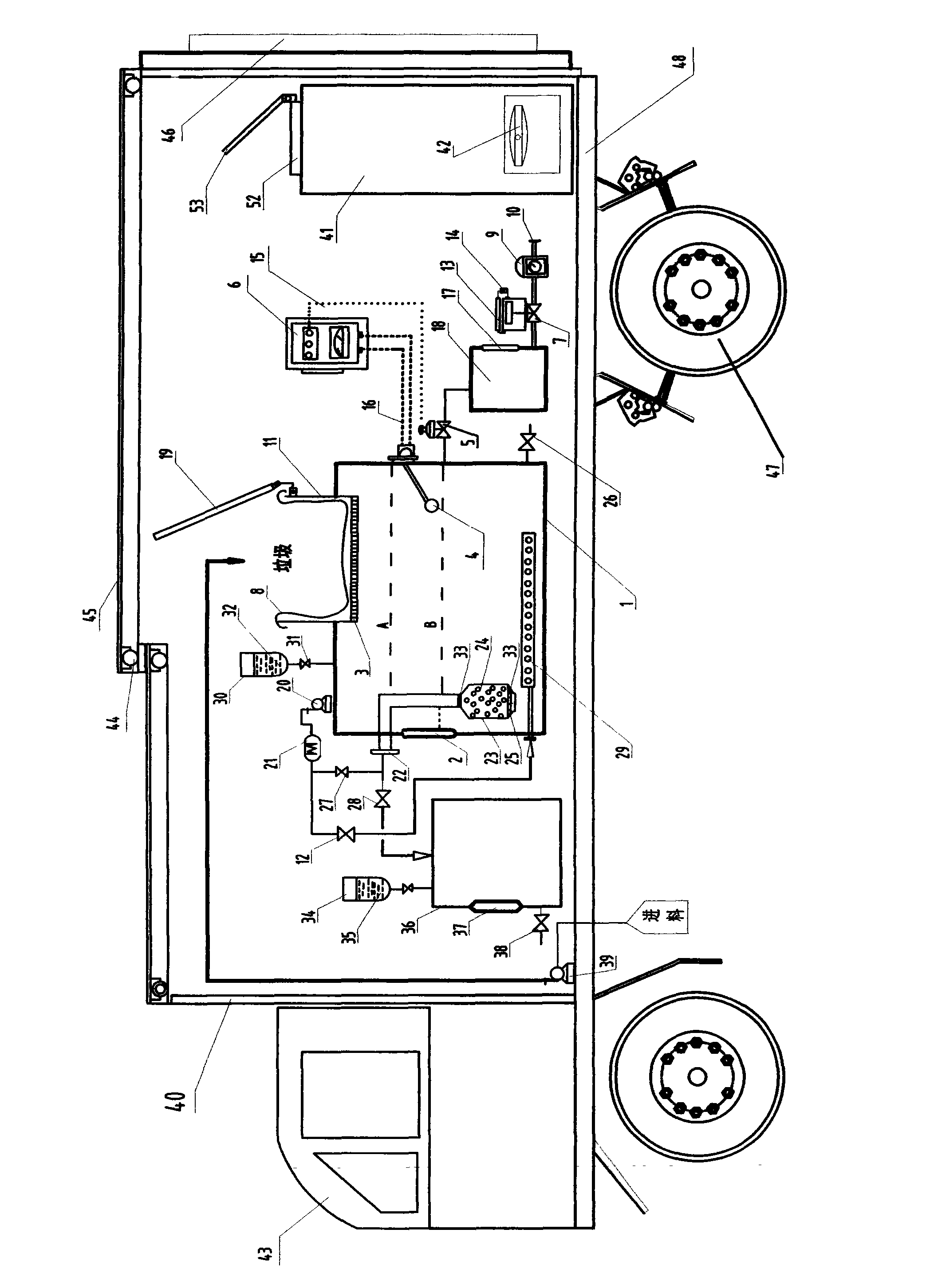

[0061] according to figure 1 , figure 2 , image 3 with Figure 4 As shown, the present embodiment 1 adopts Dongfeng Chenglong M3V box truck (model is LZ5161XXYLAS, engine: Yuchai YC4E160-33 / 160, 160 horsepower; cargo box is 7.65 meters long, 2.4 meters wide, and 2.5 meters high; load 10 tons ) as a transport vehicle (43); the "equipment for solid, oil, and water three-phase separation of kitchen waste and waste water purification and up-to-standard treatment" is arranged in the cargo compartment (40) of the transport vehicle (43), Lay one deck steel plate on the cargo compartment (40) bottom surface of vehicle (43), make steel plate and the chassis girder (48) of vehicle (43) firmly fix, and become a whole, be combined into " mobile Solid, oil and water three-phase separation of food waste and waste water purification treatment device", or simply "kitchen waste treatment vehicle";

[0062] The "equipment for solid, oil, and water three-phase separation of kitchen waste a...

Embodiment 2

[0099] according to figure 1 , figure 2 with Figure 4 Shown, present embodiment 2 adopts the rectangular casing (53) of 304 stainless steel materials, and described casing (53) size is: long 5 meters, wide 2 meters, high 1.8 meters; "Equipment for solid, oil, and water three-phase separation of kitchen waste and waste water purification and up-to-standard treatment" is configured and fixed in the box (53) as a whole, and combined into the "mobile kitchen waste" described in the present invention Solid, oil, water three-phase separation and waste water purification treatment device"; using cranes (or forklifts), and conventional flat-bed diesel trucks, will be equipped with "solid, oil, water three-phase Separation and waste water purification standard treatment equipment "box (53) is hoisted, transported, and unloaded and placed near the canteen of a certain university to perform solid-liquid separation and oil-water separation of the kitchen waste in the university cantee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com