Method for preparing quinazoline-2-thioketone

A quinazoline and the quinazoline technology are applied in the field of preparation of organic nitrogen heterocyclic compounds, and can solve the problems of increasing the preparation cost, the complexity of the process, the unsafe reaction route, the complex reaction process, and the like, and achieve a simple preparation process. Controllable, favorable for purification, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment one: catalyst [(Me 3 Si) 2 N] 3 La(μ-Cl)Li(THF) 3 Synthesis

[0035] -10°C, the n - BuLi in hexane solution (60 mmol, 2.52 M) was slowly added to the (Me 3 Si) 2 NH (60 mmol) in a 100 mL Schlenk reaction flask for 30 minutes at room temperature. The above reaction solution was added to anhydrous LaCl 3 (20 mmol) in THF (30 mL) and stirred overnight at room temperature. The solvent was removed under reduced pressure, and the obtained solid powder was extracted with hot toluene to remove LiCl, concentrated, placed at 0°C, and a large number of crystals were precipitated, which was the desired lanthanum siliconamide compound, with a yield of 85%.

[0036] Other catalysts can refer to the preparation method of Example 1.

Embodiment

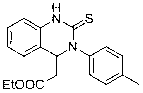

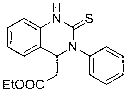

[0037] Example: [(Me 3 Si) 2 N] 3 Yb( m -Cl)Li(THF) 3 Catalytic reaction of ethyl o-aminocinnamate and phenylisothiocyanate to prepare quinazoline-2-thione

[0038] In the reaction flask treated with dehydration and deoxygenation, weigh [(Me 3 Si) 2 N] 3 Yb( m -Cl)Li(THF) 3 (0.0455 g, 0.05 mmol ), added ethyl o-aminocinnamate (0.1912 g, 1 mmol ) and phenylisothiocyanate (0.1622 g, 1.2 mmol ) in sequence, stirred at 50°C for 5 hours after mixing, added water Terminate the reaction, extract three times with ethyl acetate, dry the extract with anhydrous sodium sulfate, filter, remove the solvent under reduced pressure, and finally perform flash column chromatography on a silica gel column (eluent: ethyl acetate:petroleum ether=1:10) to obtain White solid product, 80% yield.

[0039] The theoretical molecular formula of the obtained product and the main NMR test data are as follows. It can be seen from the analysis that the actual synthesized product is consistent with t...

Embodiment 3

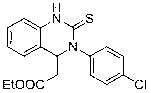

[0042] Embodiment three: [(Me 3 Si) 2 N] 3 Sm( m -Cl)Li(THF) 3 Catalytic reaction of ethyl o-aminocinnamate and phenylisothiocyanate to prepare quinazoline-2-thione

[0043] In the reaction flask treated with dehydration and deoxygenation, weigh [(Me 3 Si) 2 N] 3 Sm( m -Cl)Li(THF) 3 (0.0445 g, 0.05 mmol ), added ethyl o-aminocinnamate (0.1912 g, 1 mmol ) and phenylisothiocyanate (0.1622 g, 1.2 mmol ) in sequence, stirred at 50°C for 5 hours after mixing, added water Terminate the reaction, extract three times with ethyl acetate, dry the extract with anhydrous sodium sulfate, filter, remove the solvent under reduced pressure, and finally perform flash column chromatography on a silica gel column (eluent: ethyl acetate:petroleum ether=1:10) to obtain White solid product, 90% yield.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com