Poly-o-aminophenol antibacterial material and preparation method thereof

A technology of poly-ortho-aminophenol and antibacterial materials, which is applied in the field of antibacterial materials, can solve the problems of complex process, single preparation method, and low yield, and achieve the effects of good thermal stability, simple preparation process, and excellent antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

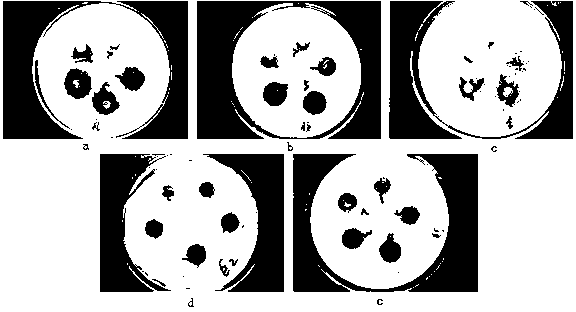

[0022] First prepare 1000ml of nitric acid solution with a molar concentration of 1.0mol / L, divide it into two equal parts, add 10.9g of o-aminophenol to one part, stir well to form A liquid; add 5.7g of ammonium persulfate to the other acidic solution , stir evenly to form liquid B, quickly pour liquid B into liquid A at room temperature, and then let it stand for reaction at room temperature for 20 hours; then use reduced-pressure filtration to separate the system formed by the reaction, and remove Wash with ionic water until the filtrate is neutral and colorless; vacuum-dry the obtained solid at 60-80°C for 12 hours to obtain a powdered poly-o-aminophenol polymer antibacterial material; poly-o-aminophenol is in the form of spherical particles Structure, the diameter is 20~50μm, known from the antibacterial results (inhibition zone method, the diameter of the attached sample paper is 6mm, the concentration is 1mg / ml): the diameter of the antibacterial zone of the obtained pol...

Embodiment 2

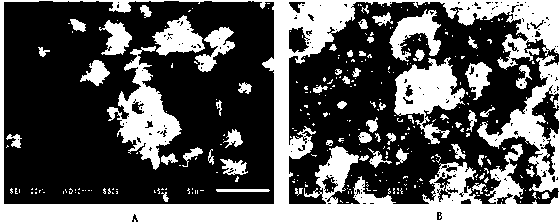

[0024] First prepare 200ml of sulfuric acid solution with a molar concentration of 1.0mol / L, divide it into two equal parts, add 5.45g o-aminophenol to one part, stir well to form A liquid; add 5.7g ammonium persulfate to the other acidic solution , stir evenly to form liquid B, quickly pour liquid B into liquid A at room temperature, and then stand for reaction at 0°C for 8 hours; then use reduced-pressure filtration to separate the system formed by the reaction, and use 1mol / L sulfuric acid solution, Wash with deionized water separately until the filtrate is neutral and colorless; vacuum-dry the obtained solid at 60-80°C for 12 hours to obtain a powdered poly-o-aminophenol polymer antibacterial material, in which poly-o-aminophenol is in the form of chrysanthemum Petal-shaped particle structure, with a diameter of about 20 μm, and its appearance is as follows figure 1 As shown in (A), it is known from the antibacterial results (inhibition zone method, the diameter of the att...

Embodiment 3

[0026] First prepare 400ml of hydrochloric acid solution with a molar concentration of 1.0mol / L, divide it into two equal parts, add 21.8g o-aminophenol to one part, stir well to form A liquid; add 4.56g ammonium persulfate to the other acidic solution , stir evenly to form liquid B, quickly pour liquid B into liquid A at room temperature, and then let stand for reaction at room temperature for 30 hours; then use vacuum filtration to separate the formed system, and use 1mol / L hydrochloric acid solution to remove Wash with deionized water until the filtrate is neutral and colorless; vacuum-dry the obtained solid at 60-80°C for 12 hours to obtain a powdered poly-o-aminophenol polymer antibacterial agent; wherein poly-o-aminophenol is smooth and micro Spherical particle structure, with a diameter of about 20 μm, and its shape is as follows figure 1 As shown in (B); from the antibacterial results (inhibition zone method, the diameter of the attached sample paper is 6mm, the concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com