Method for synthesising grafted copolymer by simultaneous chemoenzymatic process and one-pot process

A technology of graft copolymer and chemical enzymatic method, which is applied in the field of synthesis and preparation of polymer materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: chemical enzymatic method simultaneously one pot synthesis brush type graft copolymer PHAZPMA-g-(PCL) (PEG)

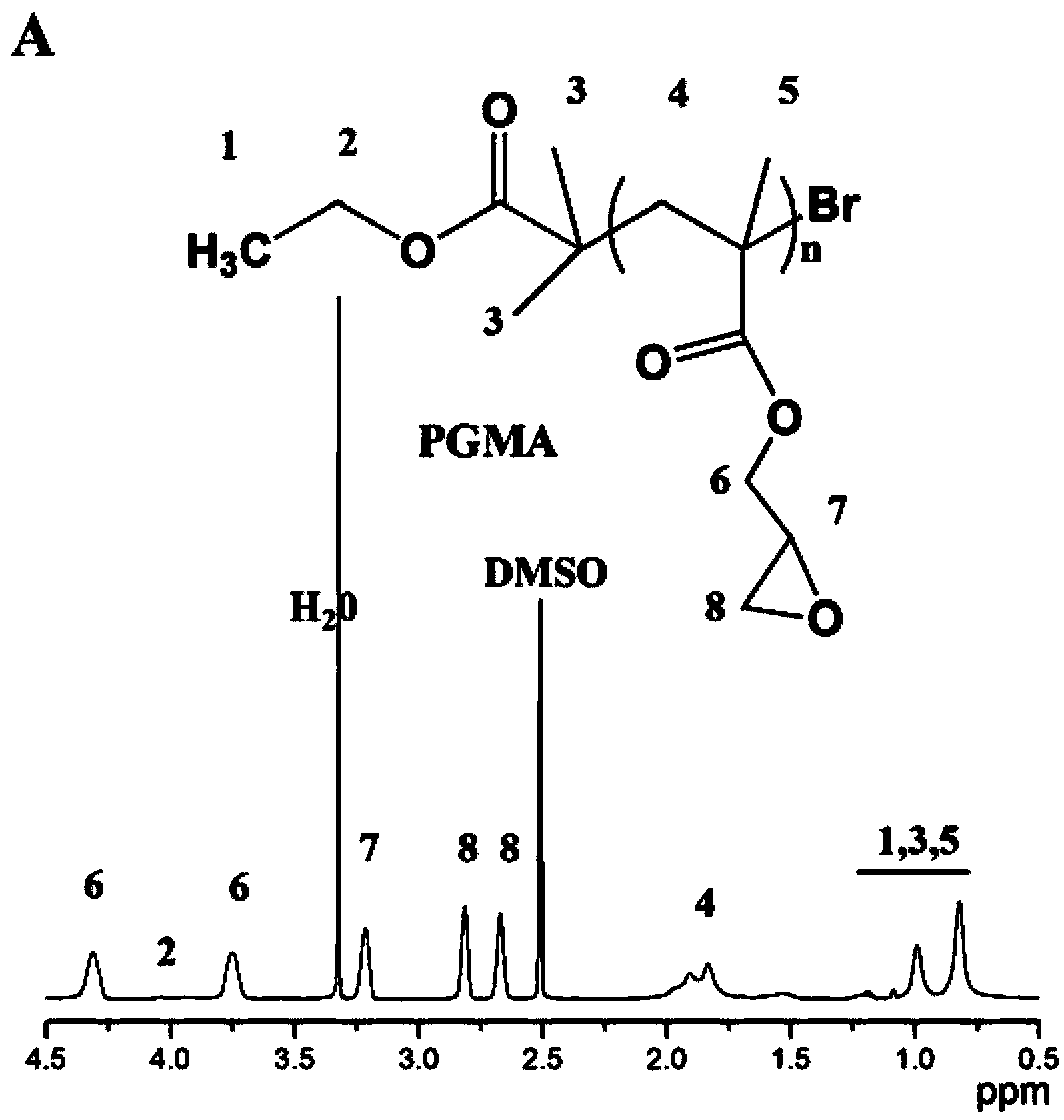

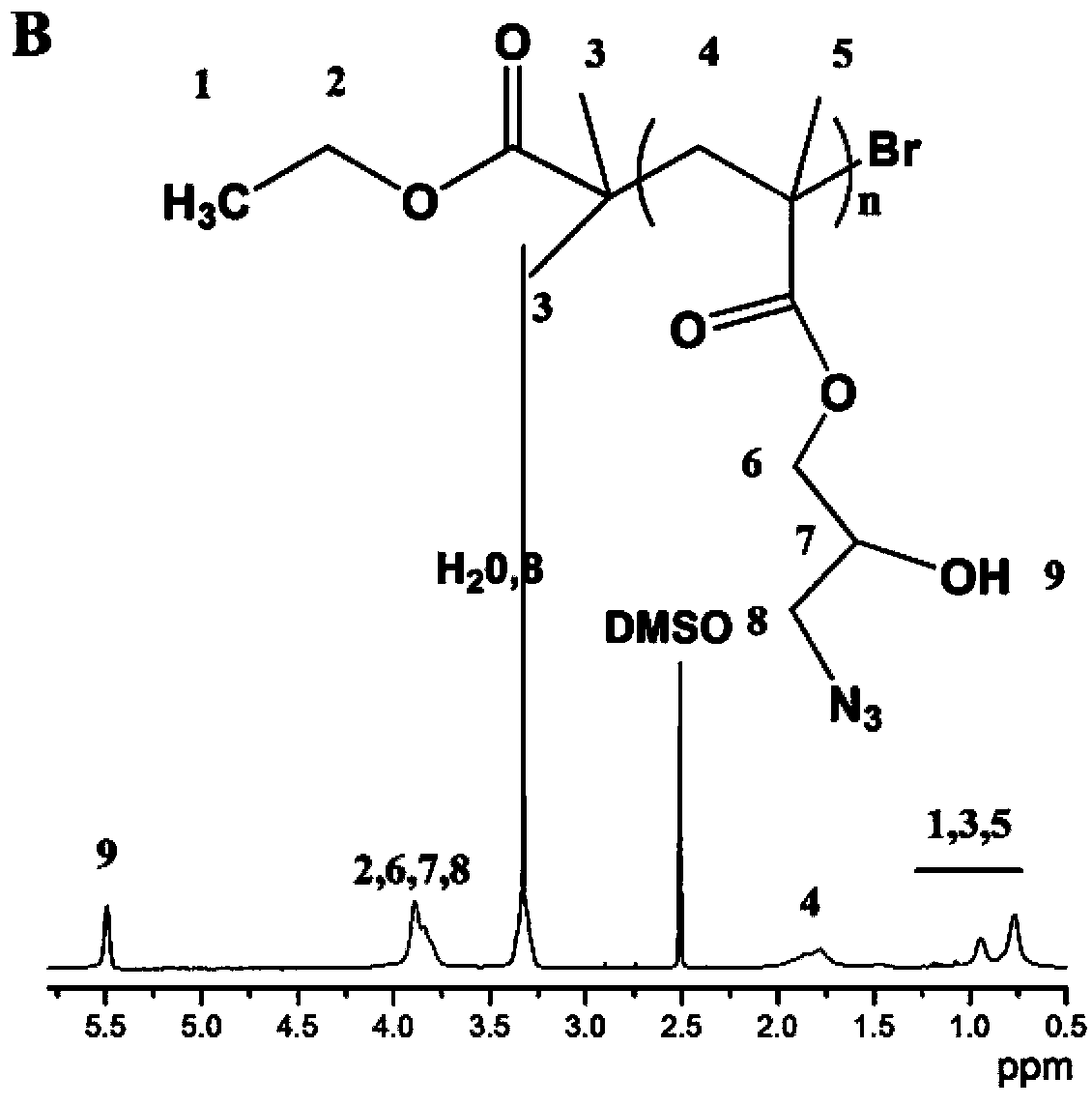

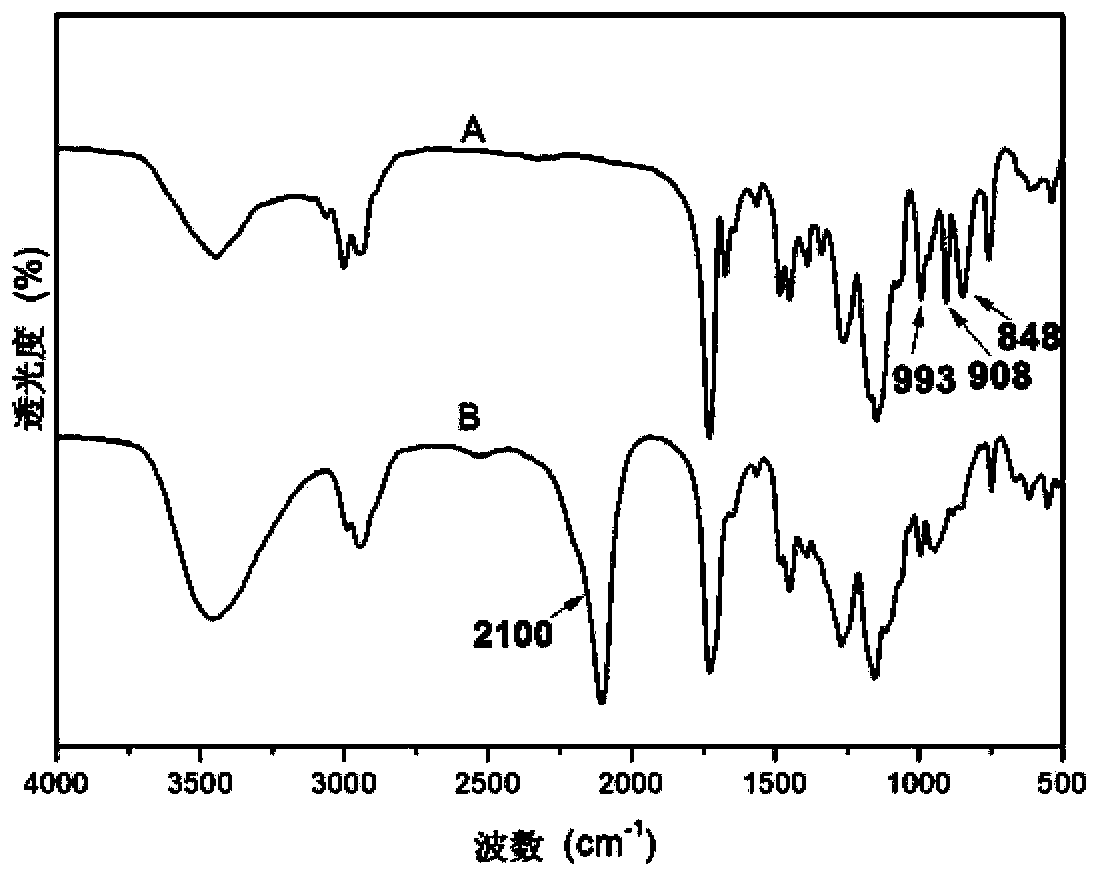

[0044] Synthesis of multifunctional macromolecular initiator PHAZPMA:

[0045] The solid components in the reaction system include: atom transfer radical polymerization catalyst system CuCl (0.06mg) and bpy (0.018mg) were transferred to a 50mL reaction bottle under the protection of argon. The liquid components in the reaction system: add argon to the reaction bottle after fully deoxygenating, in which: initiator 2-bromoisobutyrate ethyl 30 μL, atom transfer radical polymerization monomer glycidyl methacrylate (GMA) 2mL, solvent dimethylformamide (DMF) 1.4mL, seal the reaction bottle and place it in a 60°C oil bath with constant temperature and magnetic stirring for reaction. After reacting for 1-24h according to the required molecular weight, dissolve the mixture in chloroform Over neutral Al 2 o 3 The atom transfer radical polymerization catal...

Embodiment 2

[0059] Example 2: One-pot synthesis of centipede-like copolymer PHAZPMA-g-(P10-HD) (PEG) by chemical enzymatic method

[0060] The multifunctional initiator was synthesized as in Example 1.

[0061] Alkyne-PEO 2000 ) is synthesized with embodiment 1.

[0062] The reaction bottle was subjected to strict baking, vacuum degassing and argon cooling, and after repeating three times, the solid component in the reaction system was added: lipase Novozyme435 (enzymatically polymerized monomer 10-hydroxydecanoic acid (10-HD ) 5% by weight), activated molecular sieves ( Molecular sieve, activated by firing in a muffle furnace at 1000°C), catalyst system cuprous chloride / 2,2-bipyridine (CuCl / bpy), sealed. After three times of vacuum degassing and filling with argon, the liquid components: 10-hydroxydecanoic acid (10-HD) (7.52g), Alkyne-PEO 2000 Dissolve the polyfunctional macromolecular initiator PHAZPMA in 4mL of toluene, pass through argon gas to fully remove oxygen, use a sample i...

Embodiment 3

[0063] Embodiment 3: chemical enzymatic method one pot synthesis centipede shape copolymer PHAZPMA-g-(PCL) (FA)

[0064] The synthesis of multifunctional initiator PHAZPMA is as in Example 1.

[0065] Synthesis of Alkyne-Folic Acid (Alkyne-FA):

[0066] Weigh 0.50g folic acid (FA), dissolve it in 20mL DMSO, transfer to a 50mL reaction bottle, add 0.30g pentynoic acid (large excess), EDC0.58g, DMAP0.12g, place the reaction bottle at room temperature, Stir magnetically for 24h. After the reaction is over, use 1mol / L hydrochloric acid to wash the product solution repeatedly, then wash with water several times and concentrate, add chloroform to dissolve and add an appropriate amount of MgSO 4 Dry, filter to remove MgSO 4 , After distilling off the filtrate, put it into a vacuum oven for drying. Yield 82%.

[0067]

[0068] The reaction bottle was subjected to strict baking, vacuum degassing and argon cooling, and after repeated three times, the solid components in the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com