Composite plant fiber material capable of resisting biological violation and preparation method thereof

A plant fiber and composite material technology, applied in the field of biomass composite materials, can solve the problem of single protective function, achieve long-term protective function, and overcome the effect of uneven distribution of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The method for preparing composite materials bonded by thermosetting resins includes:

[0027] A) drying the plant fiber raw material unit to a moisture content of 2% to 9%;

[0028] B) Apply preservatives, adhesives and waterproofing agents to the dried plant units so that they are evenly distributed on the units to obtain blanks with glue, wax and preservatives applied. Among them, the mass ratio of adhesive, waterproofing agent and dry plant unit is (3%-15%): (0.5-1.5%): 100%; borate, copper compound and iodide three types of preservatives and composite materials The mass ratio of dry plant fiber raw materials is (0.5%-4.0%): (0.5%-4.0%): (0.1%-1.5%): 100%. The three types of preservatives are evenly mixed and applied to the unit, or Borates and copper compounds are homogeneously mixed, and iodides are applied to the unit after being homogeneously mixed with liquid glue or paraffin emulsion;

[0029] C) The above blanks are evenly paved into a slab with a single-la...

Embodiment 1

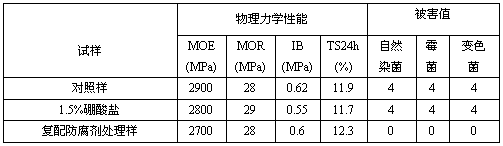

[0036] The moso bamboo is degreened and yellowed and processed into regular large pieces of shavings, and dried to a moisture content of 5%. Apply 8% urea-formaldehyde resin (with 1% hardener added) and 1% paraffin emulsion. After uniformly mixing zinc borate (0.5% of the mass of dry shavings) and copper carbonate (0.5% of the mass of dry shavings) and applying it to the shavings, uniformly mixing IPBC (0.5% of the mass of dry shavings) and adhesive The billet was obtained from the shavings, paved into a three-layer bamboo oriented strand board (OSB) slab, and pressed into a board by a hot pressing process at a temperature of 160°C-170°C, a pressure of 3.0MPa-3.5MPa, and a time of 60s / mm. At the same time, a blank control sample and a comparative test plate with zinc borate added as a preservative were prepared. According to LY / T 1580-2010 "Oriented Strand Board" test static bending strength MOR (parallel and perpendicular surface orientation direction), elastic modulus MOE (...

Embodiment 2

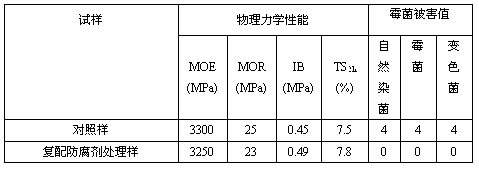

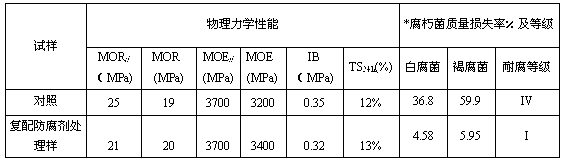

[0041] Cut moso bamboo into shavings with a flaking machine, dry to a moisture content of 5% to 6%, apply 8% PF resin and 1% paraffin wax emulsion, and mix zinc borate (0.8% of the mass of dry shavings) in a roller glue mixer. ), calcium borate (0.8% of the mass of dry shavings) and copper carbonate (1.0% of the mass of dry shavings) were uniformly mixed and applied to the shavings, and IPBC (0.4% of the mass of dry shavings) and adhesive were evenly mixed and applied to the The blank was obtained from the shavings, and the blank was paved into a slab, and pressed into a slab with a hot pressing temperature of 160°C, a pressure of 5.0 MPa, and a time of 80 s / min. According to the standard LY / T 1580-2010 "Oriented Strand Board", GB / T 18261- 2000 "Test Method for Controlling Wood Mold and Blue Stain Bacteria by Antifungal Agents", LY / T 1283-1998 "Toxicity Test of Wood Preservatives on Decaying Fungi" Laboratory test method" and GB / T 13942.1-2009 "Test method for natural durabili...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com