Composite negative pole material for lithium-ion battery and manufacturing method of negative pole material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, non-aqueous electrolyte battery electrodes, circuits, etc., can solve problems such as SnO, and achieve the effects of enhancing conductivity, suppressing volume expansion effect, and improving surface utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

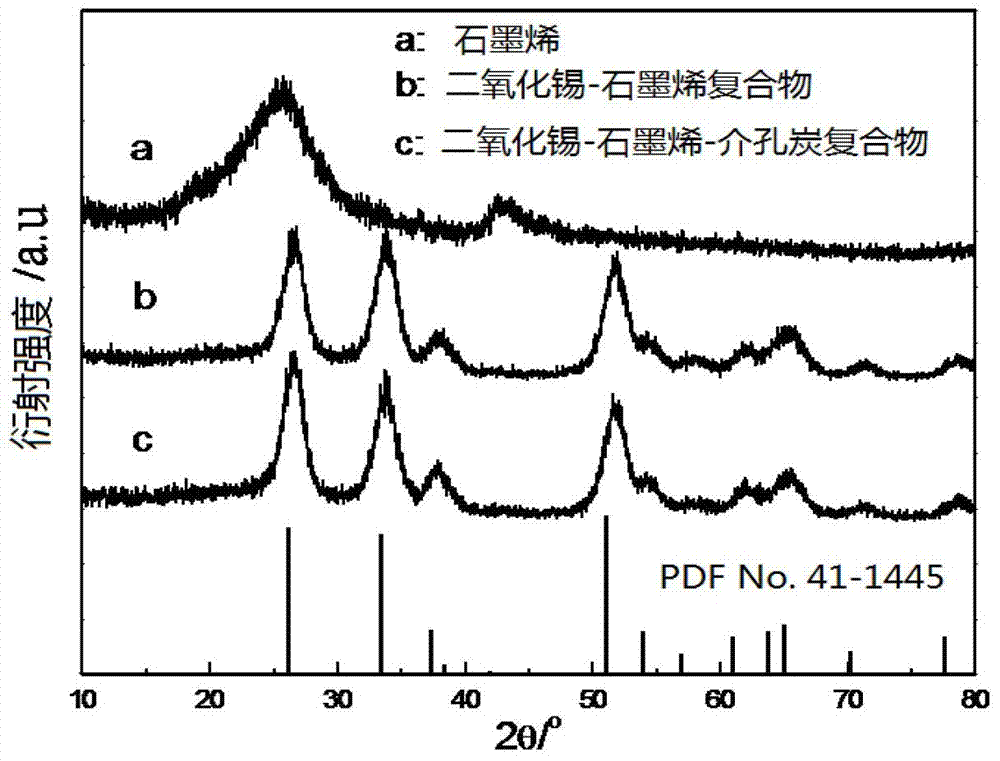

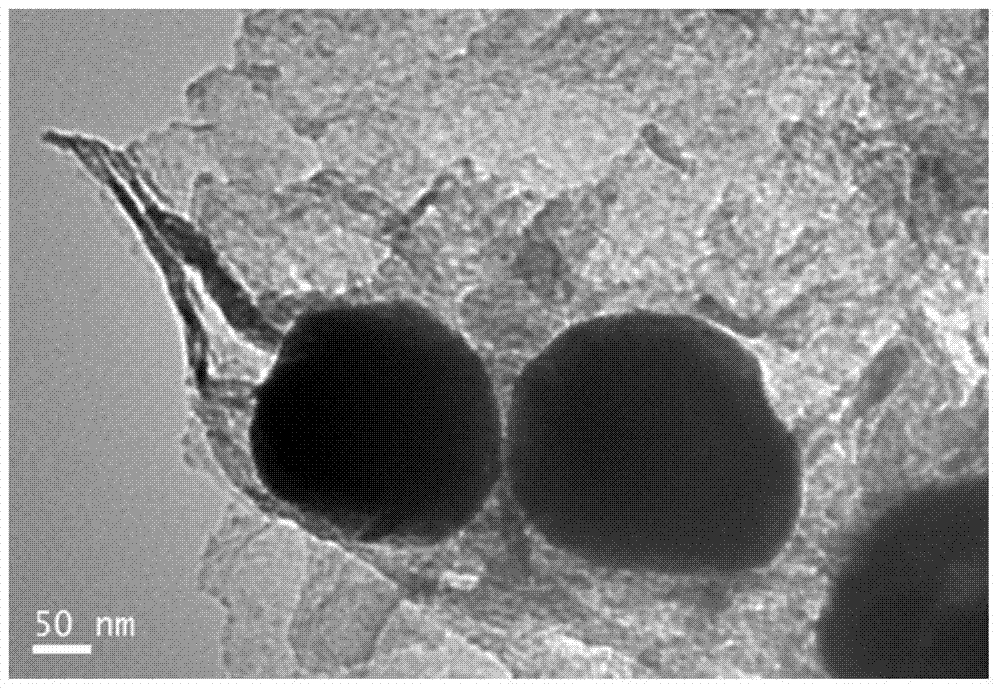

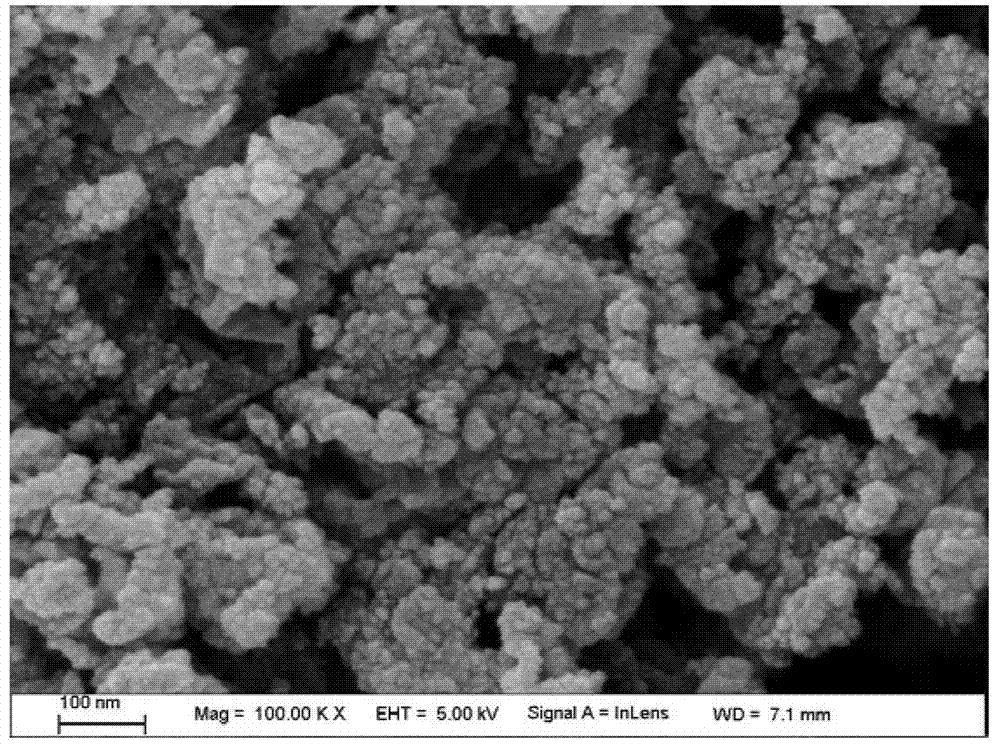

[0030] Graphite oxide (GO) was prepared by the Hummers method. Tin chloride pentahydrate (SnCl 4 ·5H 2 O) ultrasonically dissolve in deionized water equivalent to 280 times its mass, adjust the pH to 10 with 1% ammonia water, then ultrasonically disperse GO in deionized water equivalent to 20,000 times its mass, adjust the pH with 1% ammonia water to 10, then SnCl 4 : GO = 7.2: 1 mass ratio Mix the two, transfer to a high-pressure hydrothermal kettle, 160 ° C hydrothermal reaction for 24 hours, after cooling, suction filtration, and water washing, ultrasonically disperse in deionized water equivalent to 3500 times its mass. Add 20% ethanol solution of phenolic resin (molecular weight about 200), phenolic resin and SnCl 4 The mass ratio of the mixture is 0.92:1. After stirring for 20 minutes, it is transferred to a high-pressure hydrothermal kettle, subjected to a hydrothermal reaction at 160°C for 10 hours, cooled, filtered with suction, washed with water, dried in vacuum, ...

Embodiment 2

[0033] SnCl 4 ·5H 2 O was ultrasonically dissolved in deionized water equivalent to 280 times its mass, and the pH was adjusted to 9 with 1% ammonia water, and then GO was ultrasonically dispersed in deionized water equivalent to 20,000 times its mass, and the pH was adjusted to 9 with 1% ammonia water. 9, followed by SnCl 4 : GO = 4.3: 1 mass ratio, mix the two, transfer to a high-pressure hydrothermal kettle, 120 ℃ hydrothermal reaction for 24 hours, after cooling, suction filtration, and water washing, ultrasonically disperse it in a deionized solution equivalent to 3500 times its mass water, add glucose, glucose and SnCl 4 The mass ratio is 4.6:1, stirred for 20 minutes, transferred to a high-pressure hydrothermal kettle, hydrothermally reacted at 120°C for 10 hours, cooled, filtered with suction, washed with water, dried in vacuum, ground and pulverized. Under high-purity nitrogen, the obtained sample was sintered at 400 ° C for 5 h, and cooled to room temperature to o...

Embodiment 3

[0035] SnCl 4 ·5H 2 O was ultrasonically dissolved in deionized water equivalent to 280 times its mass, and the pH was adjusted to 10 with 1% ammonia water, and then GO was ultrasonically dispersed in deionized water equivalent to 20,000 times its mass, and the pH was adjusted to 10, then with SnCl 4 : GO = 5.3: 1 mass ratio, mix the two, transfer to a high-pressure hydrothermal kettle, 140 ℃ hydrothermal reaction for 24 hours, after cooling, suction filtration, and water washing, ultrasonically disperse it in a deionized solution equivalent to 3500 times its mass In water, add 20% ethanol solution of phenolic resin (molecular weight about 200), phenolic resin and SnCl 4 The mass ratio is 0.92:1, stirred for 20 minutes, transferred to a high-pressure hydrothermal kettle, hydrothermally reacted at 140°C for 10 hours, cooled, filtered with suction, washed with water, dried in vacuum, ground and pulverized. Under high-purity nitrogen, the obtained sample was sintered at 500 ° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com