A kind of method for preparing ortho esters by phase transfer catalysis in microstructure reactor

A technology of microstructure reactor and phase transfer catalysis, which is applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve the problems of high safety hazards, long cycle time, high cost, etc., and achieve high safety and reaction The effect of short time and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

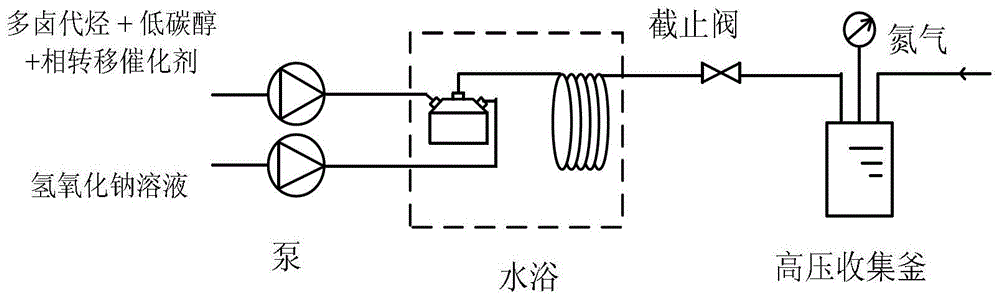

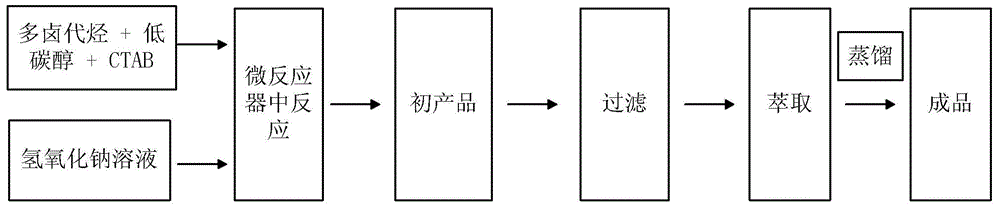

[0017] The schematic diagram of the preparation of the original esters in this embodiment is as follows figure 1 As shown, mix chloroform, ethanol and cetyltrimethylammonium bromide evenly, cetyltrimethylammonium bromide is 5% of the ethanol mass, and configure 30% mass concentration of sodium hydroxide Solution, chloroform, ethanol and sodium hydroxide are fed according to the molar ratio of 0.75:1:4, and the raw materials are pumped into the microstructure reactor whose temperature is controlled at 60°C by the high performance liquid chromatography pump, and the micromixer is used for changing Thermal mixer (SIMHEX, IMM, Germany), the channel size is 25×25×20 (μm) (length*width*height), the residence time extension tube uses 25m inner diameter of 0.5mm, FEP tube, the reaction time is controlled at After 15 minutes, the obtained reaction product entered the high-pressure collection kettle, and the pressure of the reaction system was controlled at 2 MPa. The collected product...

Embodiment 2

[0019] Mix 1,1,1-trichloroethane, ethanol and cetyltrimethylammonium bromide evenly, cetyltrimethylammonium bromide is 2% of the mass of ethanol, and configure 40% mass concentration The sodium hydroxide solution, 1,1,1-trichloroethane, ethanol and sodium hydroxide are fed according to the molar ratio of 1.5:1:1, and the raw materials are pumped into the room with a temperature controlled at 80°C by a high performance liquid chromatography pump. In the micro-structure reactor, the micro-mixer is a cross-toed mixer (HPIMM, IMM, Germany), its channel size is 25×21×37 (μm) (length*width*height), and the residence time extension tube uses 10m inner diameter 1.0mm, FEP tube, the obtained reaction product enters the high-pressure collection kettle, and the pressure of the reaction system is controlled at 0.4MPa. The collected product is first filtered to remove sodium chloride, the filtrate is extracted with chloroform, and the organic phase is distilled to obtain the product trieth...

Embodiment 3

[0021] Mix chloroform, methanol and cetyltrimethylammonium bromide evenly, cetyltrimethylammonium bromide is 8% of the quality of methanol, and configure a 45% mass concentration of sodium hydroxide solution, three Chloromethane, methanol and sodium hydroxide are fed in a molar ratio of 2.5:1:5, and the raw materials are pumped into the microstructure reactor with a temperature controlled at 40°C by a high performance liquid chromatography pump, and the micromixer is a T-type mixer (mikroglas, Germany), the channel size is 200×25 (μm) (width*height), the residence time extension tube uses 5m stainless steel 316L tube with inner diameter of 0.5mm and 2m inner diameter of 6mm, the reaction time is controlled at 60min, the obtained reaction The product enters the high-pressure collection kettle, and the pressure of the reaction system is controlled at 4MPa. The collected product is first filtered to remove sodium chloride, the filtrate is extracted with chloroform, and the organi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com