Ceramic paint and preparation method thereof as well as heating furnace tube

A technology of ceramic coating and ceramic powder, which is applied in the field of heating furnace tubes, can solve the problems of poor wear resistance, corrosion resistance, fouling resistance and slagging performance of coatings, and achieves high thermal radiation rate, improved wear resistance, high heat The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

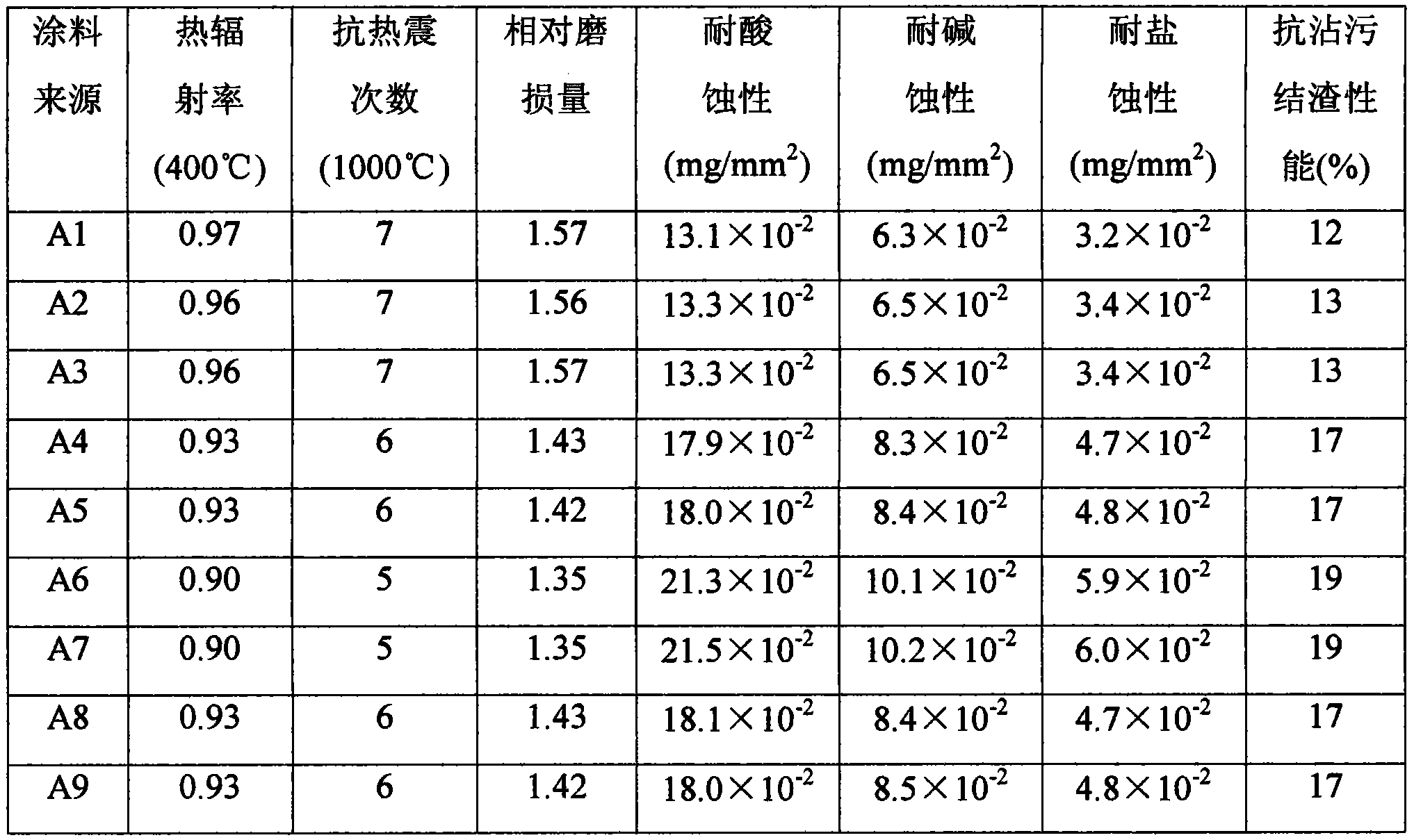

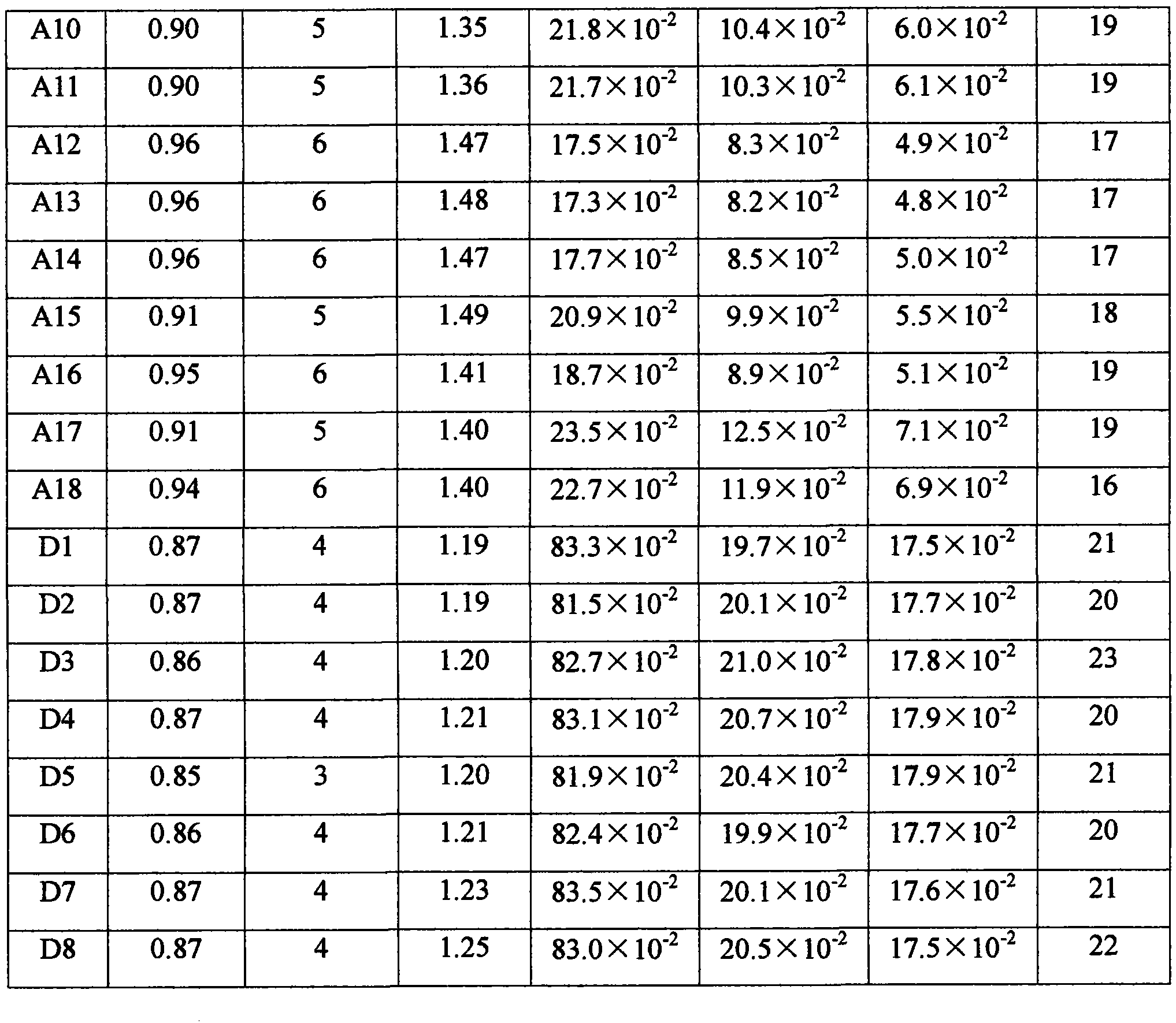

Examples

preparation example Construction

[0039] Preferably, in order to ensure that the ceramic coating has better overall performance, the preparation method of the ceramic coating comprises the following steps:

[0040] (1) mixing and grinding the ceramic powder and the rare earth metal oxide to obtain a first mixed powder;

[0041] (2) mixing and grinding the first mixed powder with the transition metal oxide, the selectively added functional material with high thermal conductivity and the titanium alloy to obtain a second mixed powder;

[0042] (3) Mixing the second mixed powder with the binder.

[0043] In the above method, the amount and substance of the ceramic powder, the rare earth metal oxide, the transition metal oxide, the binder, and the selectively added high thermal conductivity functional material and the titanium alloy The kind is such that the finally prepared ceramic paint satisfies the basic embodiment, preferred embodiment or most preferred embodiment of the aforementioned ceramic paint of the p...

Embodiment 1

[0050] This example is used to illustrate the ceramic coating provided by the present invention and its preparation method.

[0051] 86 parts by weight of CaHPO 4 2H 2 O and 14 parts by weight of calcium carbonate were mixed to obtain 100 parts by weight of ceramic powder. The ceramic powder is mixed with 30 parts by weight of rare earth metal oxide (composed of yttrium oxide, lanthanum oxide and cerium oxide, and the weight ratio of yttrium oxide, lanthanum oxide and cerium oxide is 1:1.3:1.6), and wet Ball milling for 5 hours; then add 60 parts by weight of transition metal oxide (made up of titanium oxide, chromium oxide, zinc oxide, vanadium oxide, manganese oxide and iron oxide, and titanium oxide, chromium oxide, zinc oxide, vanadium oxide, manganese oxide The weight ratio of iron oxide and iron oxide is 100:100:60:20:10:15), 30 parts by weight of silicon carbide and 20 parts by weight of titanium-molybdenum alloy (purchased from Wenzhou Tongda Bimetal Co., Ltd.), and ...

Embodiment 2

[0053] This example is used to illustrate the ceramic coating provided by the present invention and its preparation method.

[0054] 88 parts by weight of CaHPO 4 2H 2 O and 12 parts by weight of calcium carbonate were mixed to obtain 100 parts by weight of ceramic powder. The ceramic powder is mixed with 40 parts by weight of rare earth metal oxide (composed of yttrium oxide, lanthanum oxide and cerium oxide, and the weight ratio of yttrium oxide, lanthanum oxide and cerium oxide is 1:1.1:2), and wet Ball milling for 5 hours; then add 40 parts by weight of transition metal oxide (made up of titanium oxide, chromium oxide, zinc oxide, vanadium oxide, manganese oxide and iron oxide, and titanium oxide, chromium oxide, zinc oxide, vanadium oxide, manganese oxide and the weight ratio of iron oxide is 100:120:40:10:20:5), 10 parts by weight of silicon nitride and 40 parts by weight of titanium-lead alloy (purchased from Jinan Xinhaitong Special Alloy Co., Ltd.), and again Wet b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com