Preparation method for high unsaturated isoamyl alcohol polyoxyethylene ether

A technology of prenol polyoxyethylene ether and prenol, which is applied in the field of polyether synthesis in organic chemistry, can solve the problem that the molecular weight of polycarboxylic acid-based water reducing agent is difficult to meet the design requirements, the product has high PEG content, and The problems such as low flash point of pentenol can save the dehydration time, narrow molecular weight distribution and high relative molecular weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

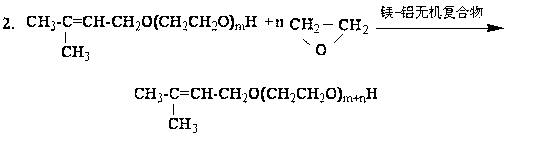

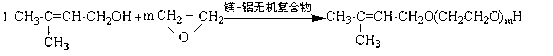

Method used

Image

Examples

Embodiment 1

[0038] Example 1 Preparation of magnesium-aluminum inorganic composite catalyst 1

[0039] Mix and grind 0.01mol aluminum nitrate and 0.09mol magnesium nitrate, add 1000ml deionized water to fully disperse, add 0.1mol sodium hydroxide and 0.03mol sodium carbonate under stirring, raise the temperature to 70°C and continue stirring for 24 hours, then place in a 70°C water bath Stand and age for 24 hours, wash with suction and water, extrude the filter cake, dry at room temperature for 8 hours, then dry in an oven above 120°C until no weight loss, and grind for later use.

Embodiment 2

[0040] Example 2 Preparation of magnesium-aluminum inorganic composite catalyst 2

[0041] Mix and grind 0.01mol aluminum nitrate, 0.01mol aluminum sulfate, 0.01mol aluminum chloride, 0.1mol magnesium nitrate, 0.05mol magnesium chloride and 0.03mol ferric chloride, add 1000ml deionized water to fully disperse, add 0.2mol sodium hydroxide under stirring and 0.03mol sodium carbonate, heated up to 60°C and continued to stir for 24 hours, then stood and aged in a 70°C water bath for 24 hours, filtered and washed with water, extruded the filter cake, dried at room temperature for 8 hours, and then Dry in an oven at 120°C until there is no weight loss, and grind for later use.

Embodiment 3

[0042] Example 3 Preparation of magnesium-aluminum inorganic composite catalyst 3

[0043]Mix and grind 0.01mol aluminum sulfate, 0.19mol aluminum chloride, 0.04mol magnesium sulfate, 0.06mol magnesium nitrate, 0.1mol magnesium chloride, 0.04mol nickel chloride and 0.06mol iron oxide, add 1000ml deionized water to fully disperse, add under stirring 0.15mol sodium hydroxide and 0.03mol sodium carbonate, heated to 75°C and continued to stir for 24 hours, then left to age in a 70°C water bath for 24 hours, filtered and washed with water, extruded the filter cake, and dried at room temperature for 8 hours , and then dried in an oven above 120°C until no weight loss, and then ground for later use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com